Intelligent sorting device for panel furniture

A sorting device, a technology of panel furniture, applied in the direction of sorting, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of sticking dust and debris, no furniture cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

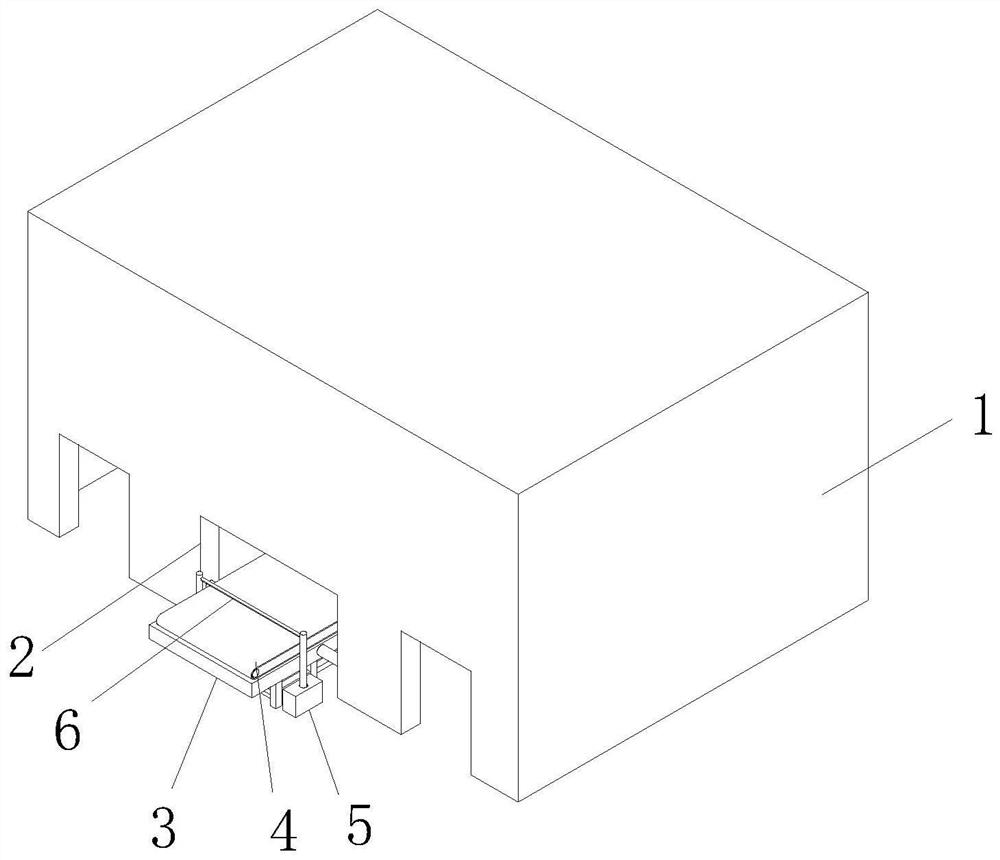

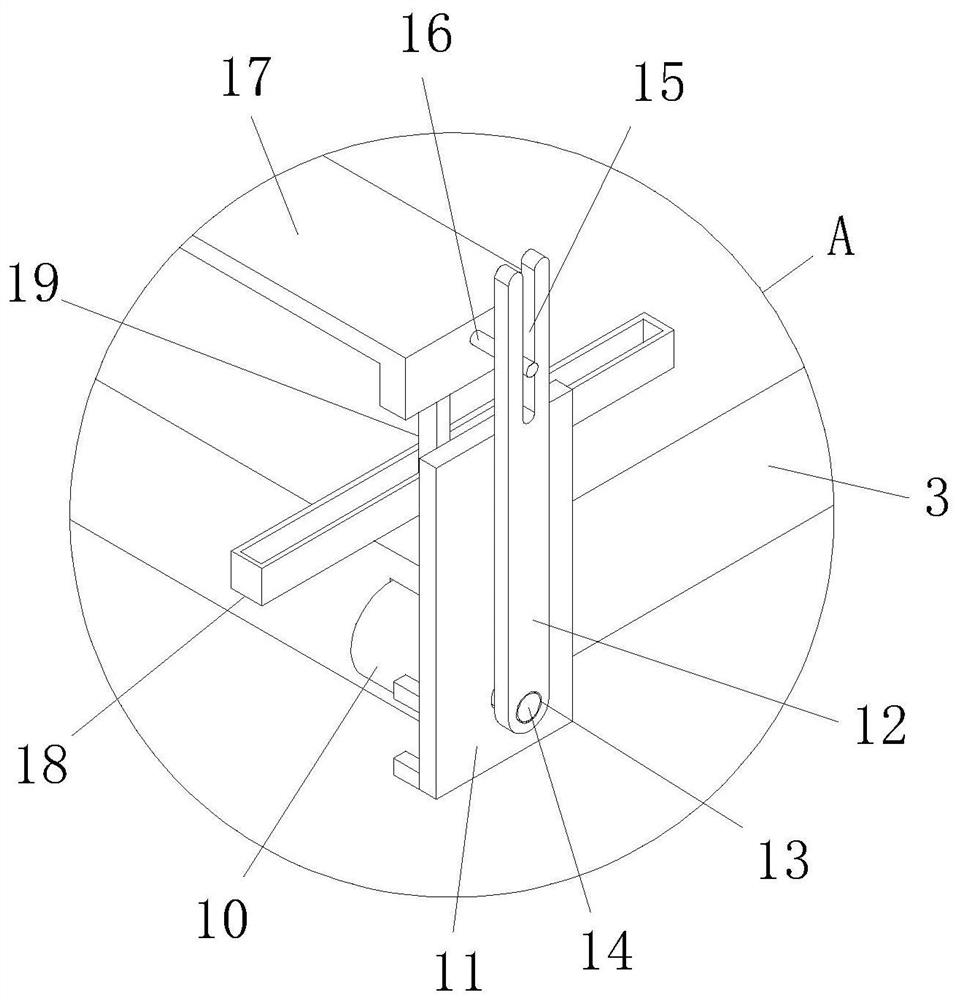

[0031] Example 1: Please refer to Figure 1-5, a panel furniture intelligent sorting device, including a warehouse 1, the outer wall of the warehouse 1 is provided with a warehouse door 2, the warehouse door 2 is a rectangular through hole, the interior of the warehouse door 2 is fixedly installed with a frame 3, and the frame 3 runs through the warehouse 1, a conveyor belt 4 is provided on the upper wall of the frame 3, two cylinders 5 are fixedly installed on the outer wall of the frame 3, and a brush 6 is fixedly installed between the piston rods of the two cylinders 5, and the outer wall of the frame 3 is provided with There are two circular grooves, and the interior of the two circular grooves on the outer wall of the frame 3 is fixedly equipped with a stepper motor 10, and the outer wall of the frame 3 is fixedly installed with two connecting plates 11, the connecting plate 11 is a rectangular structure, and the connecting plate The outer wall of 11 is provided with circ...

Embodiment 2

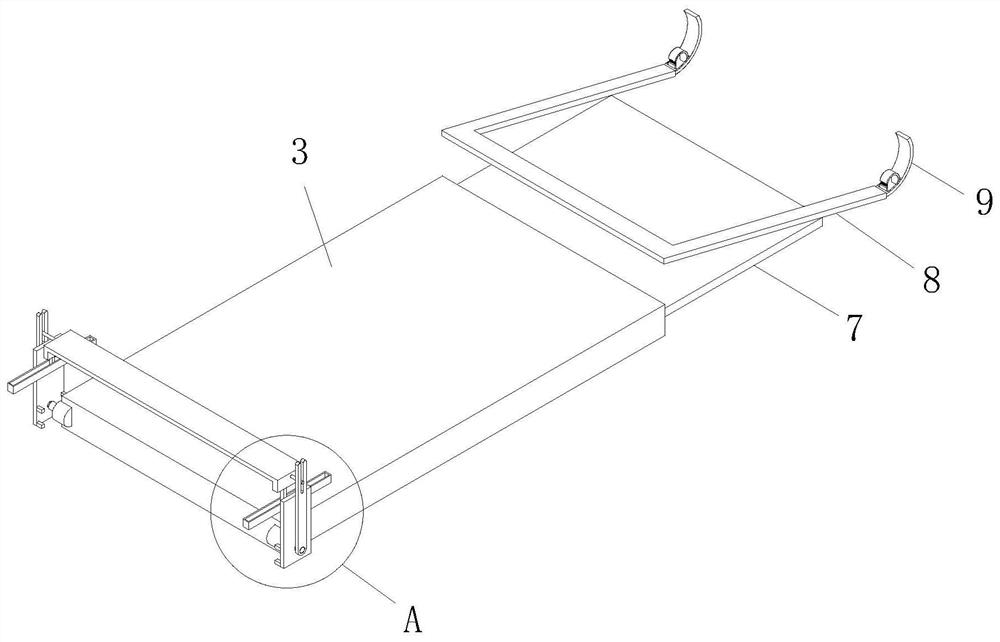

[0033] Embodiment two: on the basis of embodiment one, as figure 2 , the outer wall of the frame 3 is fixedly equipped with a fixed plate 7, the fixed plate 7 is a rectangular structure, the top of the fixed plate 7 is fixedly installed with a guide frame 8, the guide frame 8 is a frame shape and the guide frame 8 is in a downwardly inclined state, the guide frame The outer wall of 8 is fixedly installed with two abutment frames 9, and the abutment frame 9 is an arc structure.

[0034] Working principle: A guide frame 8 is fixedly installed on the top of the fixed plate 7. The guide frame 8 is frame-shaped and the guide frame 8 is inclined from top to bottom toward the side away from the frame 3. When the fixed frame 17 slides back and forth, it will Drive the cleaning brush 21 on the elastic frame 20 to slide back and forth on the surface of the panel furniture sliding on the conveyor belt 4. After the panel furniture slides to the end of the frame 3 on the conveyor belt 4, ...

Embodiment 3

[0035] Embodiment three: on the basis of embodiment two, as Figure 6 , the outer wall of the bracket 9 is provided with a notch 26, the notch 26 is an arc-shaped through hole, and the inside of the notch 26 is fixedly installed with an elastic elastic clamp 27, the elastic clamp 27 is a U-shaped structure, and the elastic clamp 27 The outer wall is provided with a connection groove 28, and the anti-slip block 29 is a rectangular groove. The interior of the connection groove 28 is fixedly equipped with an anti-slip block 29, the anti-slip block 29 is a spherical structure, and the anti-slip block 29 is made of elastic rubber material. The inner wall area of the connecting groove 28 is set.

[0036] Working principle: through the fixed installation of elastic elastic clamp 27 inside the notch 26, when the fixed frame 17 slides back and forth, it will drive the cleaning brush 21 on the elastic frame 20 to slide back and forth on the surface of the panel furniture that slides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com