Axial thrust balancing structure and method for adjustable steam extraction type steam turbine

A technology of axial thrust and balanced structure, which is applied in the direction of mechanical equipment, machines/engines, etc., can solve the disadvantages of increasing power generation and heat supply, increasing the power consumption loss of steam turbine operation, and increasing the cost of adjustable extraction steam turbines, etc. problem, to achieve the effect of ensuring the axial thrust range, increasing power generation, and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

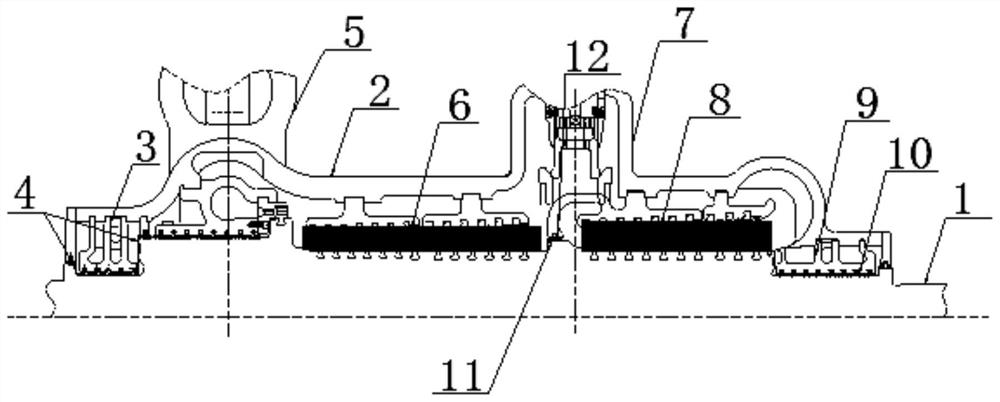

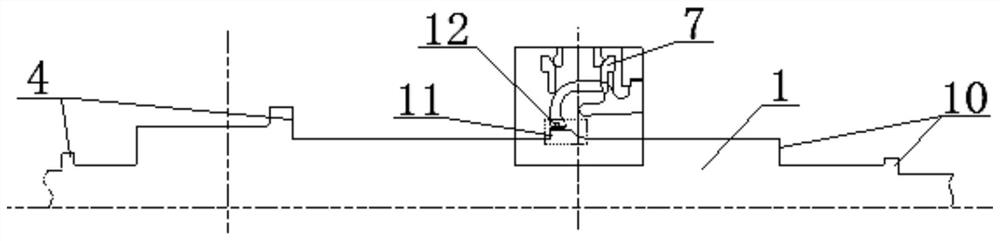

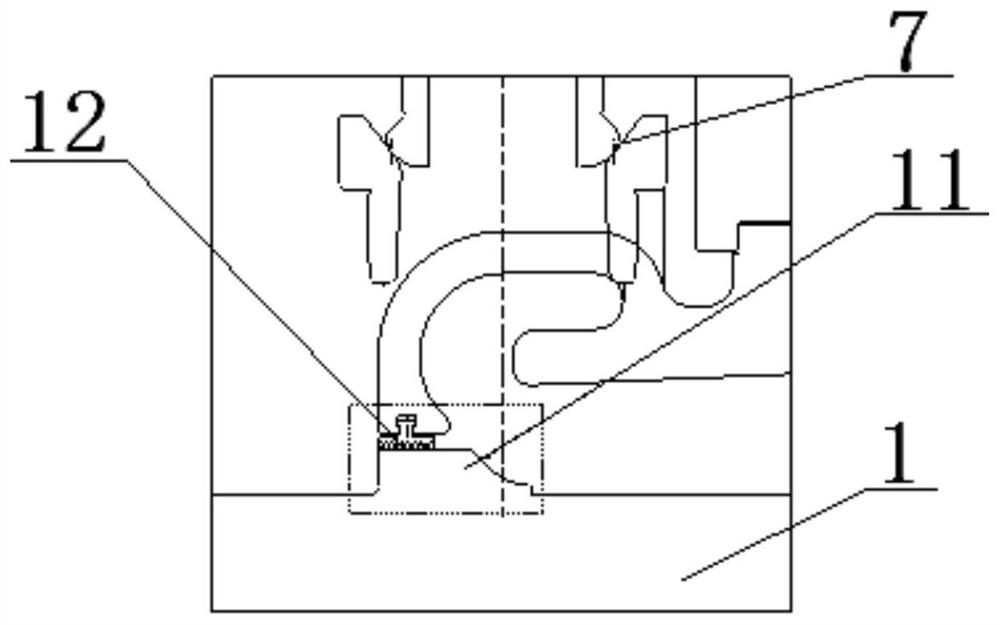

[0043] The steam extraction method of the adjustable steam extraction steam turbine of the present invention is a steam extraction regulating valve structure, see for details figure 1 , figure 2 and image 3 As shown, including rotor 1 and cylinder 2.

[0044]A main steam valve 5 is connected to the steam inlet at the front end of the cylinder 2, and a steam extraction regulating valve 7 is connected to the steam extraction port in the middle of the cylinder 2.

[0045] The front end of the rotor 1 is provided with a balance piston 4 at the front shaft seal with a rotor shoulder structure, and the rear end of the rotor 1 is provided with a balance piston 10 at the rear shaft seal with a rotor shoulder structure.

[0046] The rotor 1 is assembled in the cylinder 2 through the supporting structures at both ends, the front shaft seal 3 is arranged between the front end of the cylinder 2 and the front end of the rotor 1, the rear shaft seal 9 is arranged between the rear end of...

Embodiment 2

[0074] The steam extraction method of the adjustable steam extraction steam turbine of the present invention is a steam extraction rotating baffle structure, see for details Figure 5 and Image 6 As shown, including rotor 1 and cylinder 2.

[0075] A main steam valve is connected to the steam inlet at the front end of the cylinder, and a steam extraction rotary baffle 13 is arranged at the steam extraction port in the middle of the cylinder 2 .

[0076] The front end of the rotor is provided with a balance piston at the front shaft seal with a rotor shoulder structure, and the rear end of the rotor is provided with a balance piston at the rear shaft seal with a rotor shoulder structure.

[0077] The rotor is assembled in the cylinder through the support structures at both ends, the front shaft seal is set between the front end of the cylinder and the front end of the rotor, the rear shaft seal is set between the rear end of the cylinder and the rear end of the rotor, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com