High-pressure sterilizer for laboratory

A high-pressure sterilization and laboratory-used technology, which is applied to sanitary equipment for toilets, water supply devices, heating, etc., can solve problems such as troublesome and time-consuming, and achieve the effects of simple operation, improved work efficiency, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

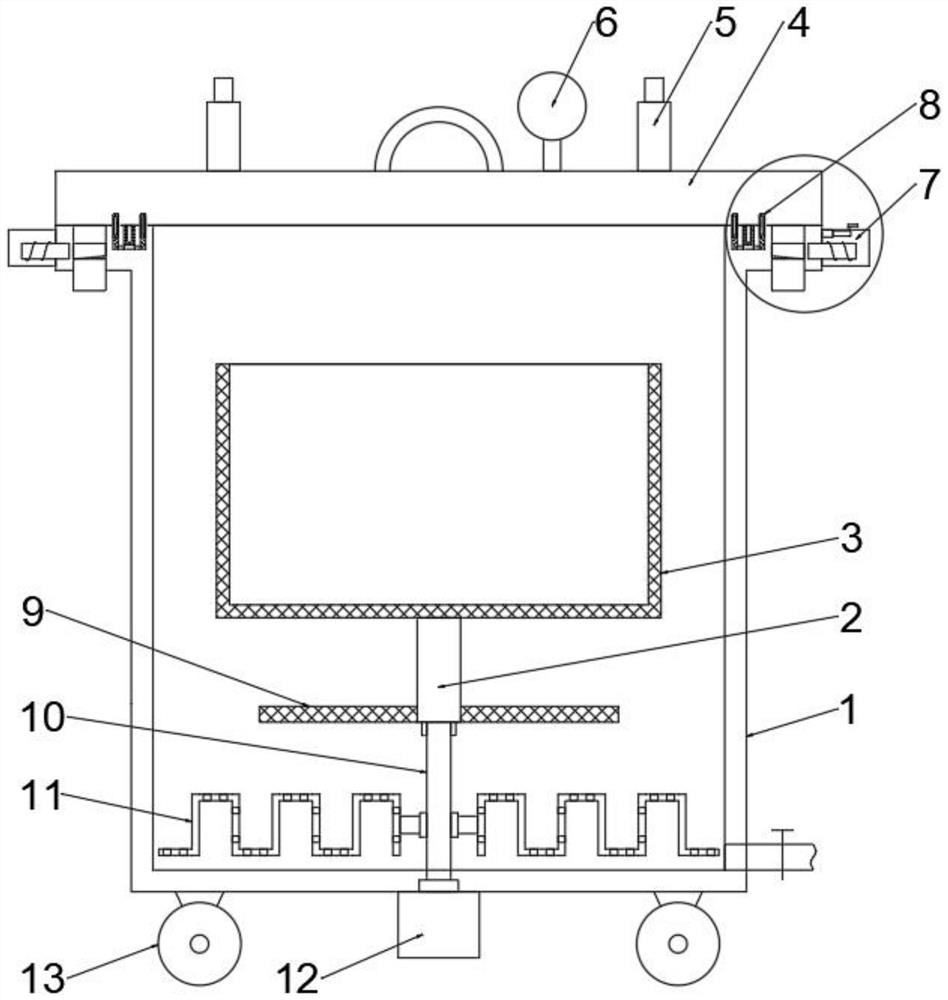

[0059] Embodiments of the present invention provide a laboratory autoclave, such as Figure 1-3As shown, including the tank body 1 and the tank cover 4 installed on the tank body 1, rollers 13 can be evenly and symmetrically installed on the bottom of the tank body 1 to facilitate movement. The tank cover 4 is equipped with a manual air release valve 5 and a pressure gauge 6. The manual air release valve 5 is used to discharge the air in the tank body 1, the pressure gauge 6 is used to monitor the pressure in the tank body 1, and the tank cover 4 is equipped with a handle for easy access;

[0060] The autoclave also includes:

[0061] The placing net frame 3 arranged in the tank body 1 is used for placing items to be sterilized, such as laboratory test tubes, beakers, Erlenmeyer flasks and other tools;

[0062] The heating assembly arranged on the tank body 1 is used to heat the water in the tank body 1 to generate water vapor;

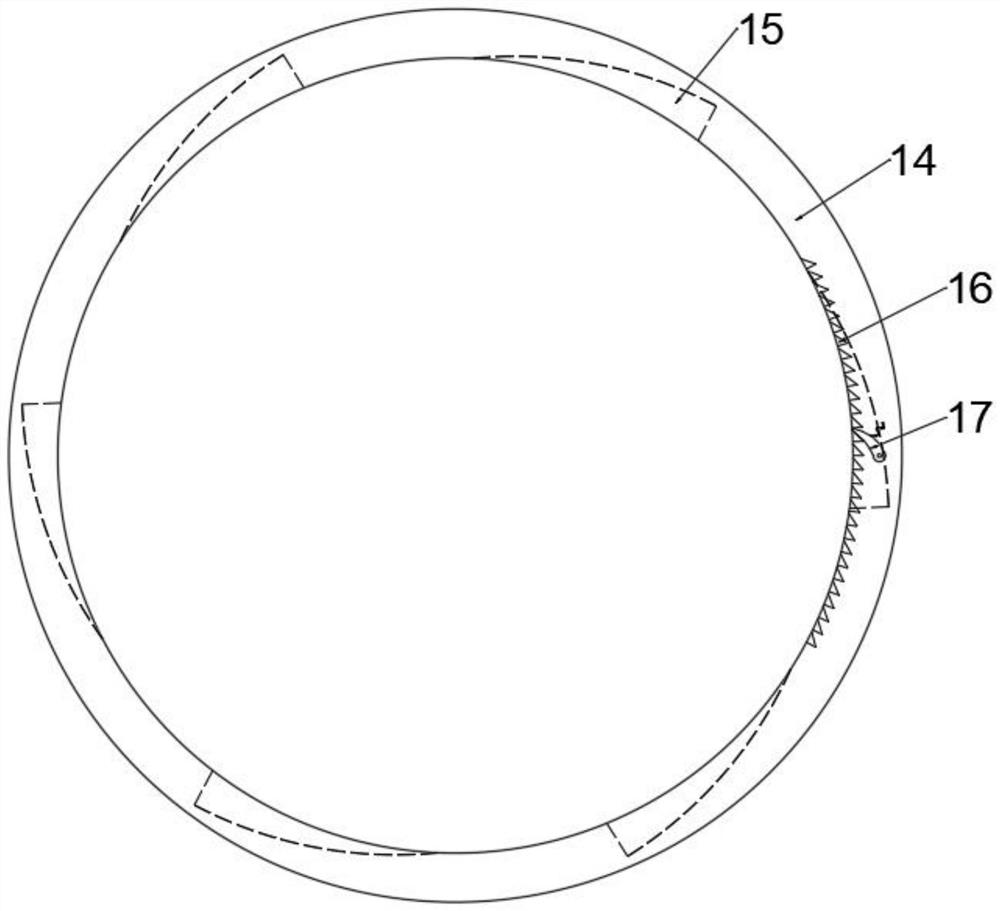

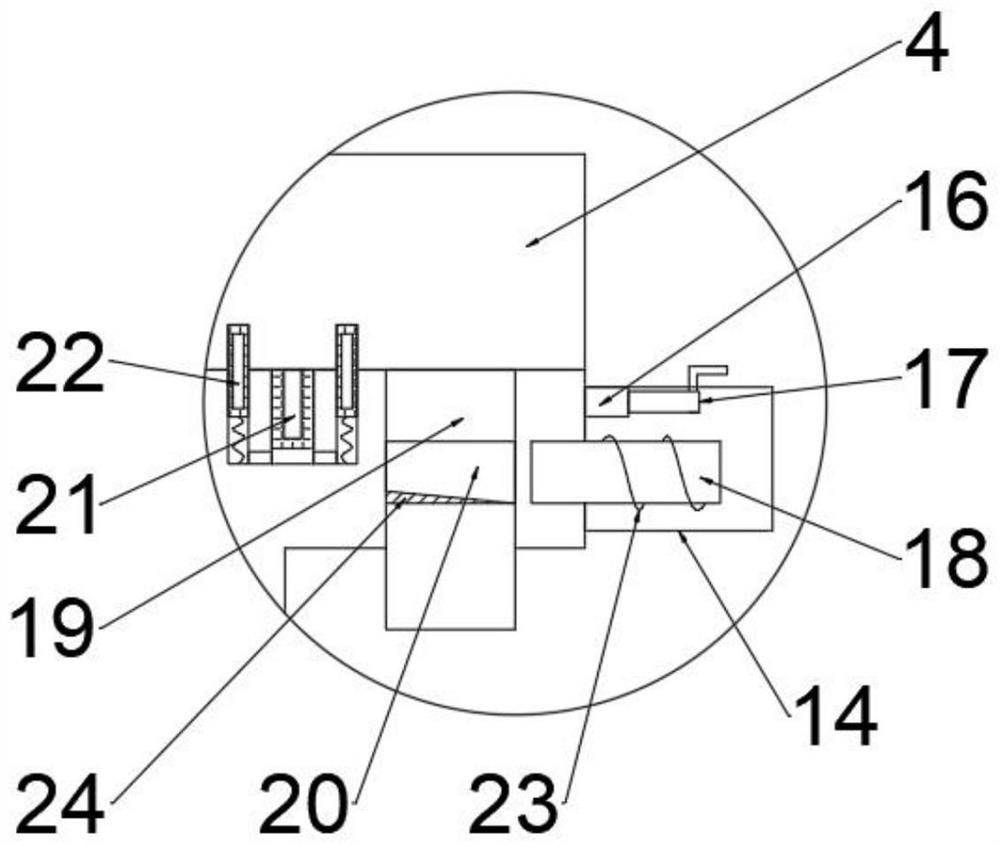

[0063] A connection assembly 7 for quickly co...

Embodiment 2

[0081] This embodiment is on the basis of embodiment 1, as Figure 4-5 shown, also includes:

[0082] A plurality of deflectors 25 arranged on the outside of the screen frame 3 are used to guide the rising water vapor into the screen frame 3, and the plurality of deflectors 25 are fixed on the inner wall of the tank body 1 at intervals from top to bottom , the distance between a plurality of shrouds 25 and the placement screen frame 3 gradually increases from top to bottom;

[0083] Water vapor all moves upwards directly, causing a certain degree of loss, and is also unfavorable for the side sterilization of the article. Through the guide cover 25, its inner side wall is inwardly arc-shaped, and the rising water vapor is changed to flow direction, from the placement net. The side of the frame 3 flows into the net frame to sterilize the side of the article, which improves the sterilization effect.

[0084] Preferably, the bottom end of the connection sleeve 2 is fixed with a ...

Embodiment 3

[0086] This embodiment is on the basis of embodiment 2, as Figure 6-7 As shown, it also includes a plurality of groups of guide assemblies mounted on the support net plate 9 at intervals in the circumferential direction, and the guide assemblies include:

[0087] At least one fan blade 26 installed on the supporting grid plate 9 and distributed radially through the installation shaft;

[0088] Worm wheel 27 fixed on the mounting shaft;

[0089] Rotate the worm screw 29 installed on the support screen 9, the worm screw 29 is engaged with the worm wheel 27;

[0090] The impeller 28 fixed on the worm 29, the impeller 28 is partly submerged in the water in the tank body 1, and the impeller 28 is driven to rotate by hydraulic force so that the worm 29 rotates, and the blades of the impeller 28 are preferably arc-shaped;

[0091] When the rotating shaft 10 drives the support screen 9 to rotate, the impeller 28 revolves accordingly and moves relative to the water. The force of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com