System and method for additive forming of metal parts

A technology of additive molding and metal parts, which is applied in the field of metal 3D printing, can solve the problems of unsmooth powder falling, easy clogging, and easy powder sputtering, etc., and achieve the effects of improving reliability, smooth pushing, and accurate powder feeding volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

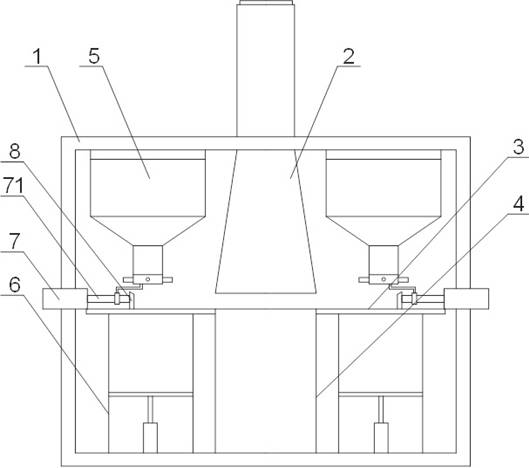

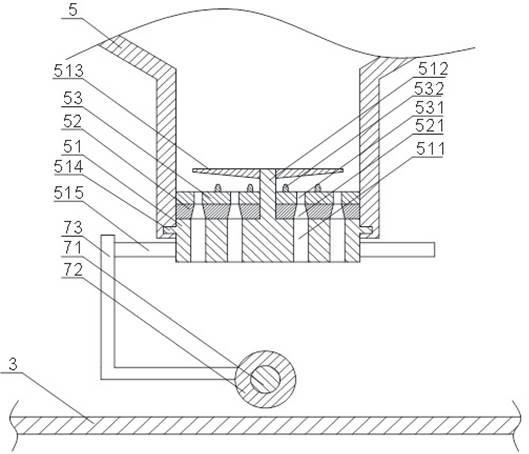

[0057] like Figure 1 to Figure 3 A metal part additive molding system as shown includes a molding chamber 1, and a powder spreading platform 3 is arranged in the molding chamber 1, and a molding cylinder 4 and a lower powder box 6 are arranged under the powder spreading platform 3, and the powder spreading platform 3 is provided. An upper powder box 5 is arranged above the platform 3, and a first driving device 7 is arranged on the powder spreading platform 3. The first driving device 7 is used to drive the scraper 8 to be transferred from the upper powder box 5 or the lower powder box 6 to the powder spreading. The metal powder on the platform 3 is scraped and sent to the forming cylinder 4 for printing. The heat insulating frame 2 is arranged above the forming cylinder 4, and the bottom of the upper powder box 5 is provided with a feeding tray 52. The feeding tray 52 is provided with several The second through hole 521 , a rotating plate 51 rotatable relative to the unloa...

Embodiment 2

[0063] On the basis of Example 1, as Figure 2 to Figure 5 In the illustrated metal parts additive molding system, the rotating plate 51 is provided with a connecting column 512, the connecting column 512 movably penetrates the unloading plate 52 and extends to the top of the unloading plate 52, the connection The column 512 is provided with a stirring plate 53 located above the unloading plate 52. The stirring plate 53 is provided with a plurality of third through holes 531. In the open state, the third through holes 531 are connected to the first through holes. 511 and the second through hole 521 together constitute a blanking channel.

[0064] In some embodiments, the connecting column 512 is provided with a first stirring member 513 , and the diameter of the first stirring member 513 gradually decreases along the direction from the connecting column 512 to the inner wall of the upper powder box 5 .

[0065] In some embodiments, an annular second stirring member 532 is dis...

Embodiment 3

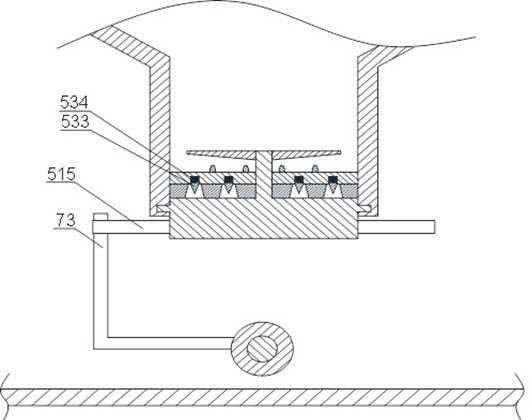

[0072] On the basis of Example 2, as image 3 , Figures 6 to 8 As shown, a first groove is formed on the lower surface of the stirring plate 53, a spring 534 is arranged in the first groove, and a scraper 533 is connected to the spring 534. In the open state, the The scraping member 533 is integrally located in the first groove. In the closed state, the scraping member 533 enters the second through hole 521 to scrape the metal powder in the second through hole 521 .

[0073] like Figure 8 As shown, in the open state, the scraper is entirely located in the first groove, the spring is compressed at this time, and the bottom of the scraper is in contact with the upper surface of the unloading tray. like Figure 7 As shown, in the closed state, with the rotation of the stirring plate, the first groove is aligned with the second through hole, and the scraper that loses its blocking is squeezed into the second through hole under the force of the spring, scraping , Squeeze the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com