Card type certificate cleaning method and equipment

A technology for cleaning equipment and certificates, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of toxic gas, easy open flame, waste cards, etc., and achieve the effect of high cleaning power, convenient combination, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

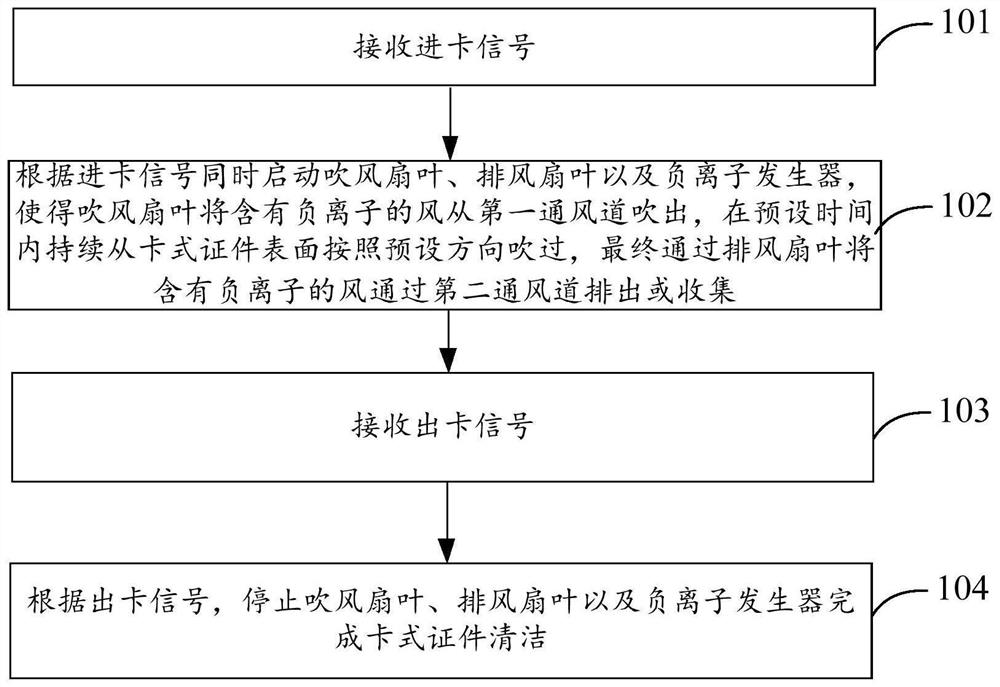

[0035] refer to figure 1 , shows a flow chart of steps of a method for cleaning a card-type certificate according to Embodiment 1 of the present application.

[0036] The method for cleaning card-type certificates in this embodiment includes the following steps:

[0037] Step 101, receiving a card-in signal;

[0038] Optionally, receiving the card entering signal includes: regularly monitoring the trigger signal of the card entering sensor interface, and receiving the card entering signal.

[0039] In one embodiment, before the surface information of the card is etched by laser, it needs to be transported to the laser etching position through the card transport structure, which is also the position for negative ion cleaning. Before the location, when the card-feeding sensor installed on the card-type document transmission structure detects that the card-type document enters from the card-feeding entrance, it will receive the card-feeding signal from the controller by regular...

Embodiment 2

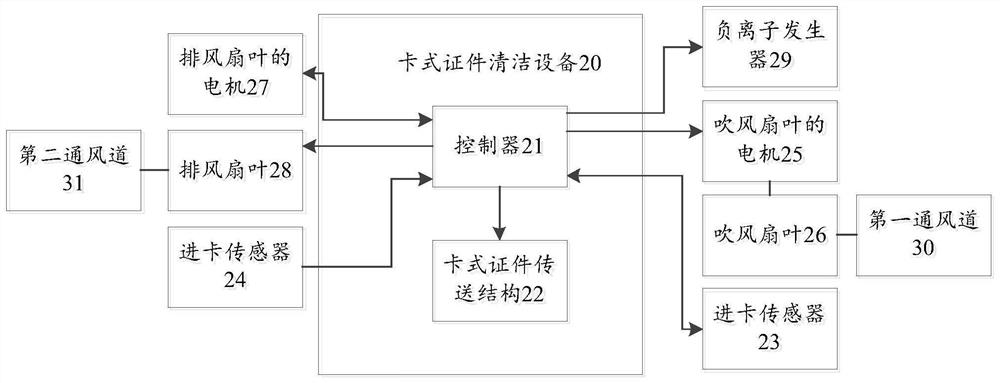

[0053] refer to figure 2 , shows a schematic block diagram of a card-type document cleaning device according to Embodiment 1 of the present application.

[0054] According to the second aspect of the embodiment of the present application, a card-type document cleaning device 20 is provided, including: a controller 21, a card-type document transmission structure 22, a card-in sensor 23, a card-out sensor 24, and a motor 25 for blowing fan blades , blowing fan blade 26, motor 27 of exhaust fan blade, exhaust fan blade 28, negative ion generator 29;

[0055] The card certificate transmission structure 22 is used to transmit the card certificate;

[0056] The card-feeding sensor 23 is used to send a card-feeding signal to the controller 21 when it is detected that the card-type certificate is passed into the cleaning platform;

[0057] Controller 21 is used to control the motor 25 of blowing fan blade, the blowing fan blade 26, the motor 27 of exhaust fan blade, the exhaust fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com