A fully automatic stair handrail processing equipment

A technology for stair handrails and processing equipment, which is used in wood processing appliances, manufacturing tools, multi-purpose machinery, etc., and can solve problems such as low production efficiency and inapplicability to mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The following description serves to disclose the invention to enable those skilled in the art to practice the invention. The preferred embodiments described below are given by way of example only, and other obvious modifications will occur to those skilled in the art.

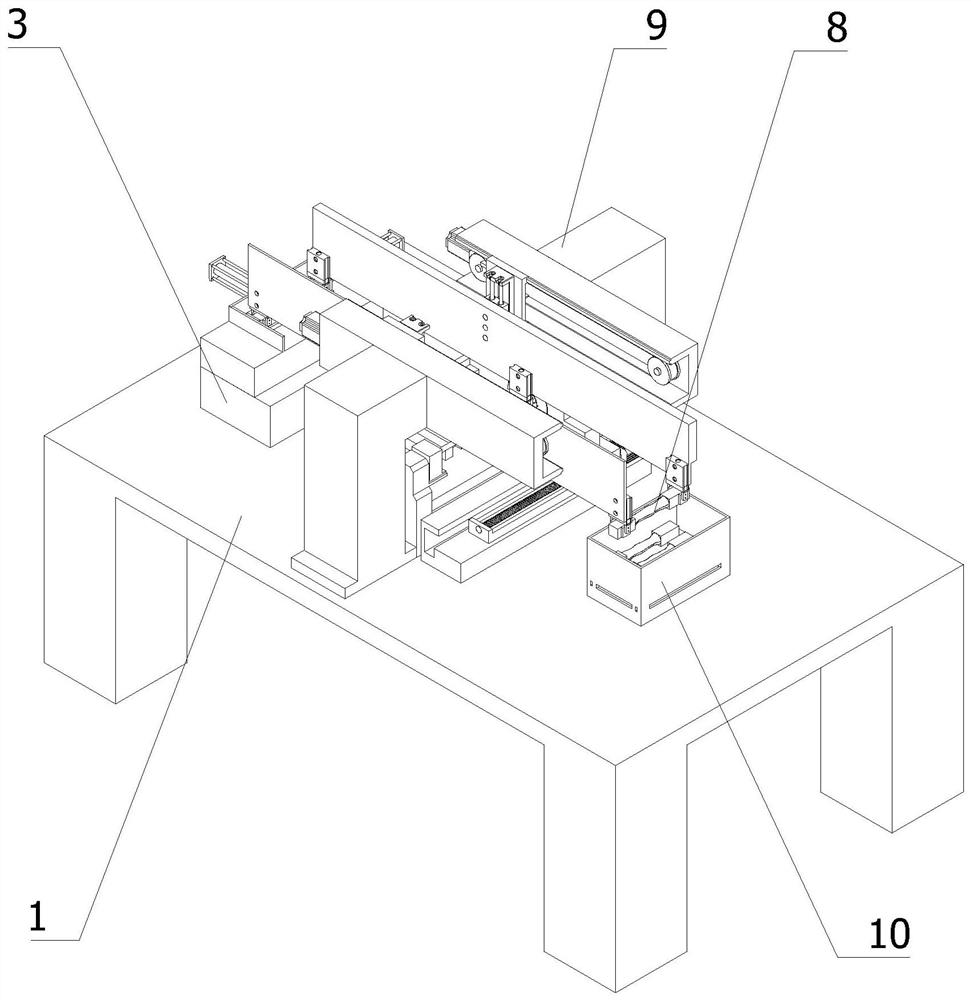

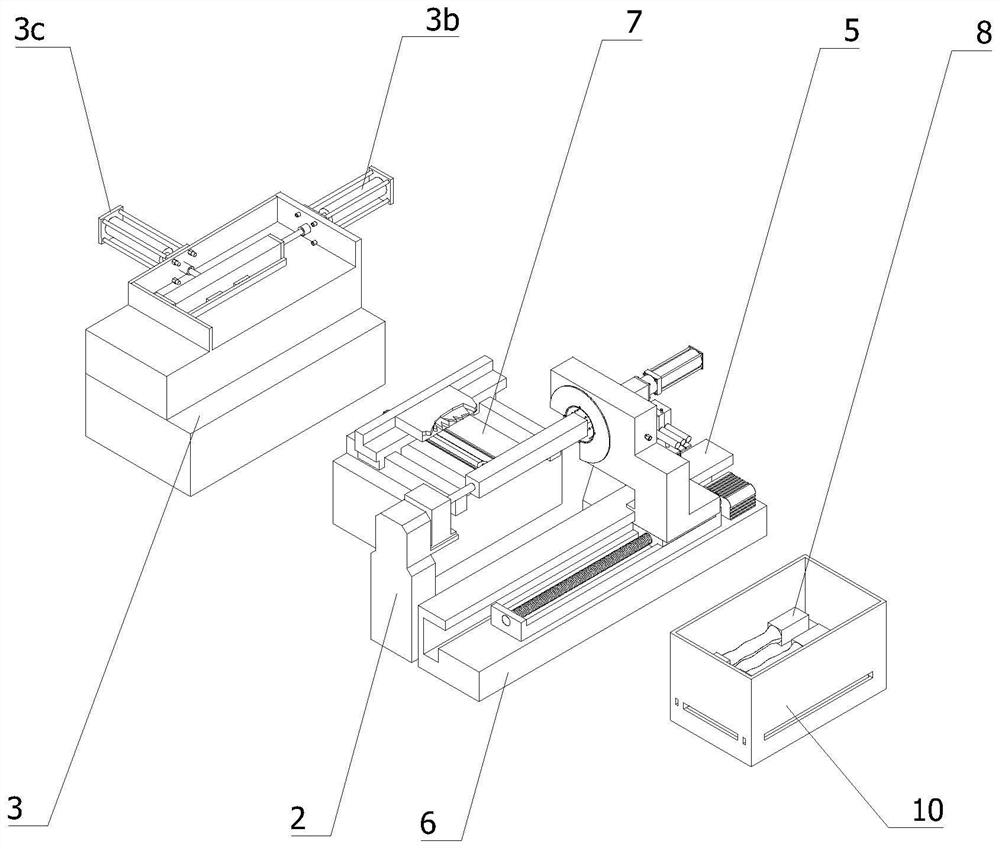

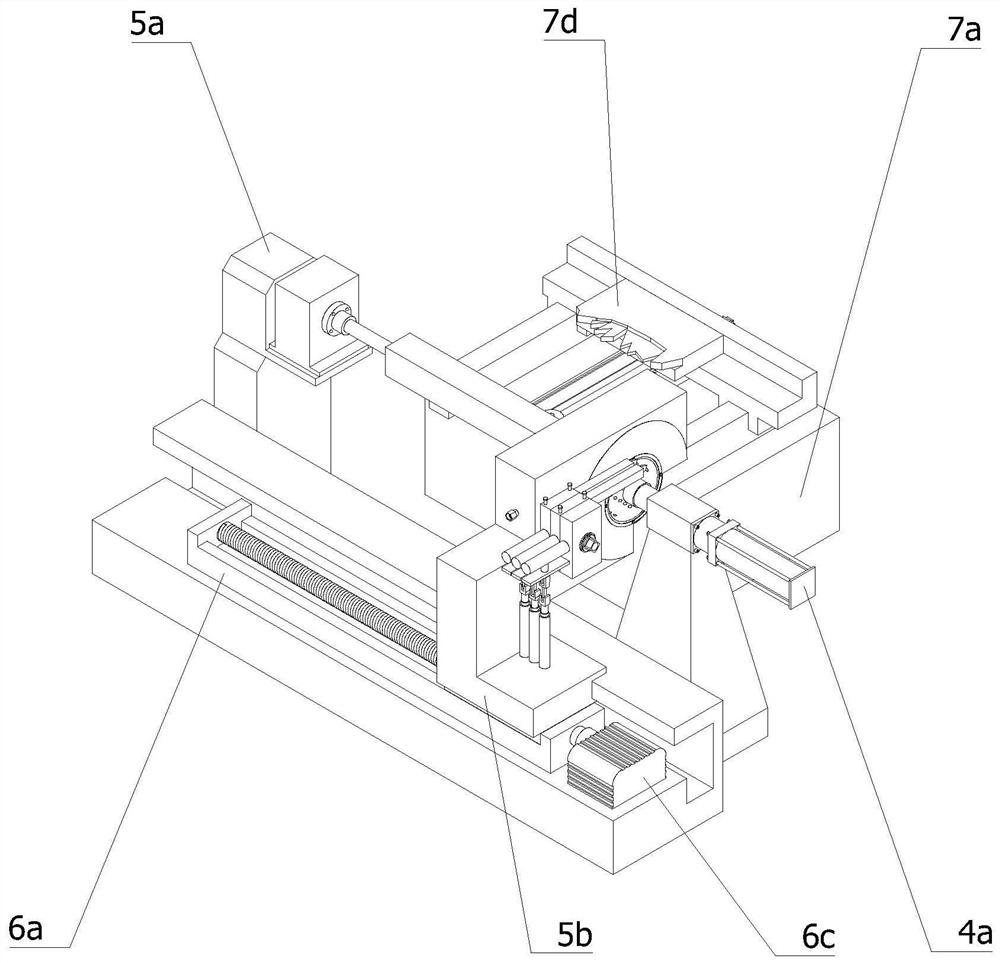

[0082] In order to solve the technical problem of changing from semi-automatic processing of stair handrails to fully automatic processing of stair handrails, such as Figure 1-10 As shown, the following technical solutions are provided:

[0083] A fully automatic processing equipment for stair handrails, which is used for processing wood 2 into stair handrails 8, is characterized in that it includes a workbench 1 and a

[0084] The fixture 4, the fixture 4 is rotatably installed on the workbench 1, and the fixture 4 is used to clamp the wood 2;

[0085] The feeding table 3, the wood 2 is placed on the feeding table 3, and the feeding table 3 is arranged on one side of the fixture;

[0086] The first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com