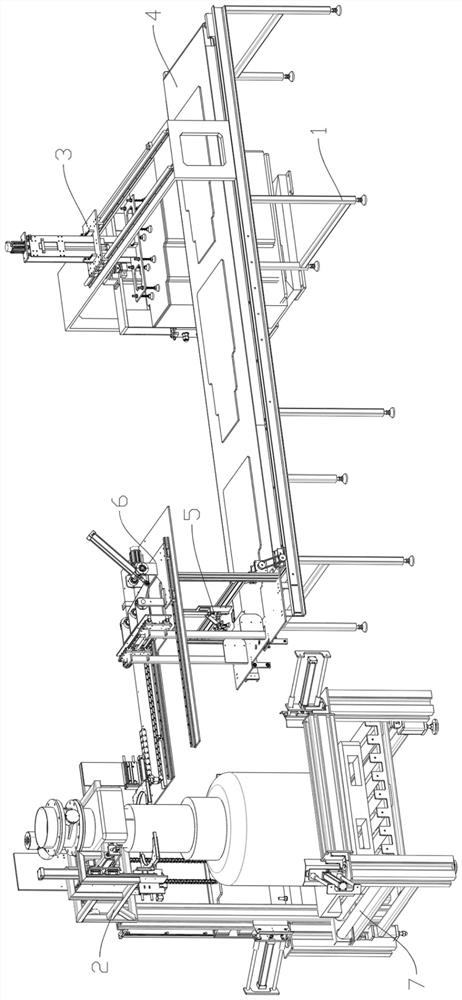

Full-automatic ton bag filling machine

A filling machine, fully automatic technology, applied in the directions of packaging, transportation and packaging, packaging item types, etc., can solve the problems of low degree of automation and poor uniformity, and achieve the effect of high filling efficiency and uniform powder weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

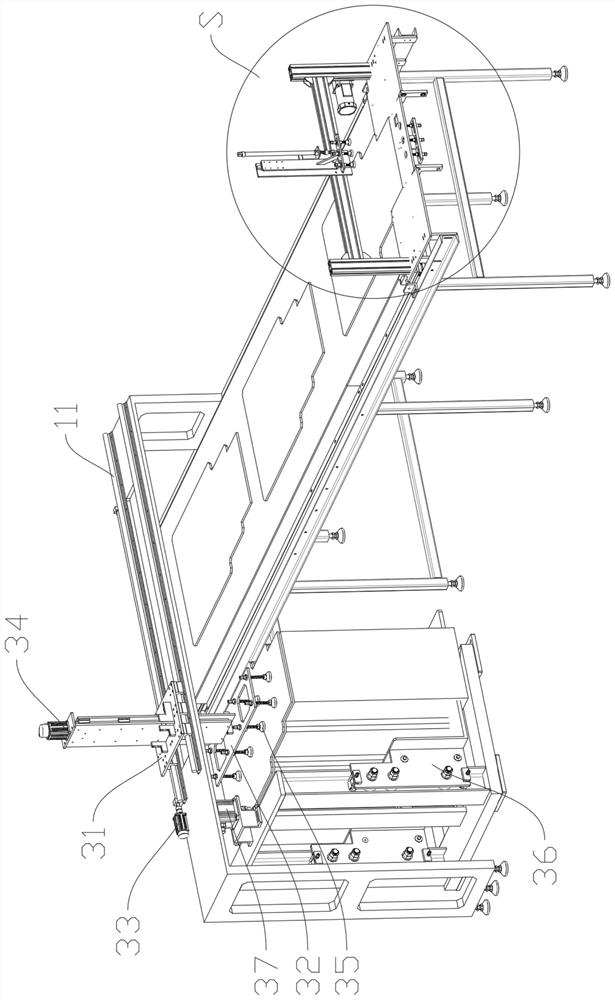

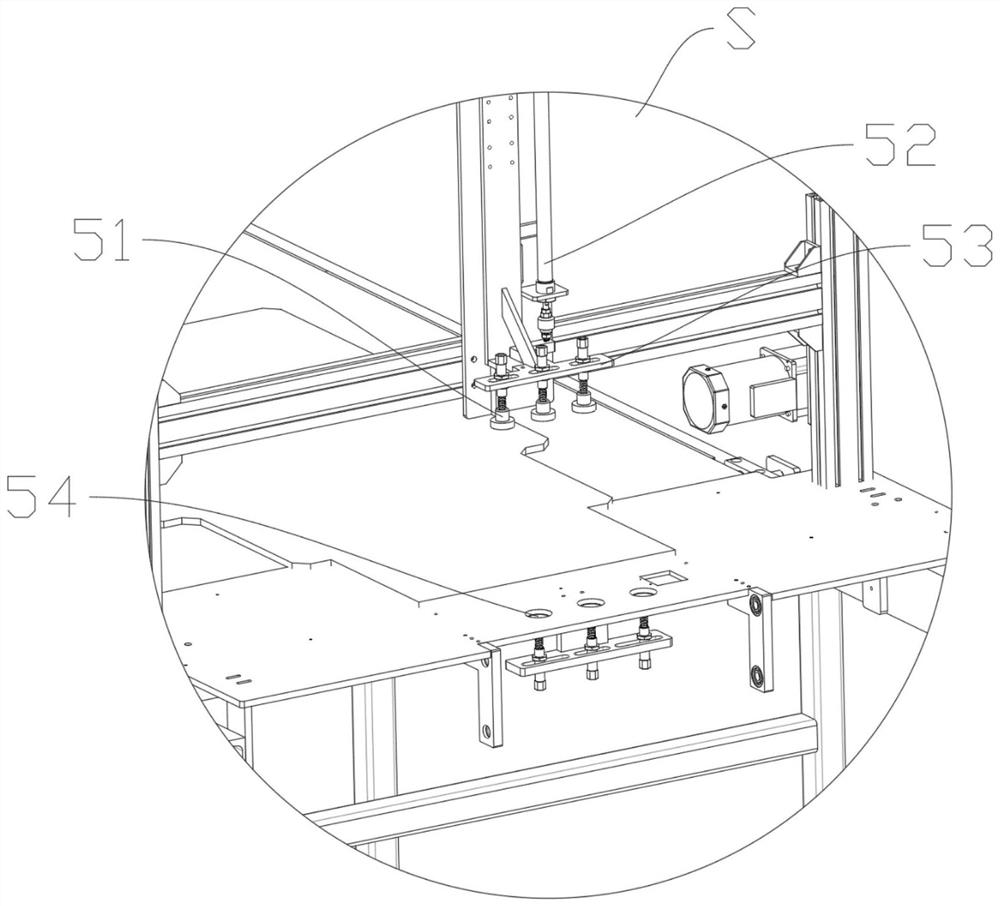

[0046] Further, the present invention also provides a preferred embodiment of the working process of the equipment. Taking a packaging bag filled with 500Kg as an example in the present invention, a single layer of packaging bags is covered by a sorting device 3 or a packaging bag feeding device. Set on the barrel 202, the splints 203 on both sides of the barrel 202 shrink inwardly to clamp the packaging bag on the barrel 202, and at the same time blow air into the packaging bag through the barrel 202, so that the packaging bag can Inflated and formed to avoid filling failure due to the small internal space of the packaging bag; when the powder is filled to a certain value (usually tens of kilograms), the lifting seat 201 will descend on the base frame 1, so that The bottom of the packaging bag can touch the third conveying device 7 below and provide data to the weighing device; As the packaging bag descends, the bottom of the packaging bag is fully in contact with the third c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com