Concentrating photovoltaic power generation matrix and system convenient to install

A photovoltaic power generation and easy installation technology, applied in the field of photovoltaic power generation, can solve the problems of high price, inconvenient installation, and high cost, and achieve the effect of ensuring vertical installation and convenient calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

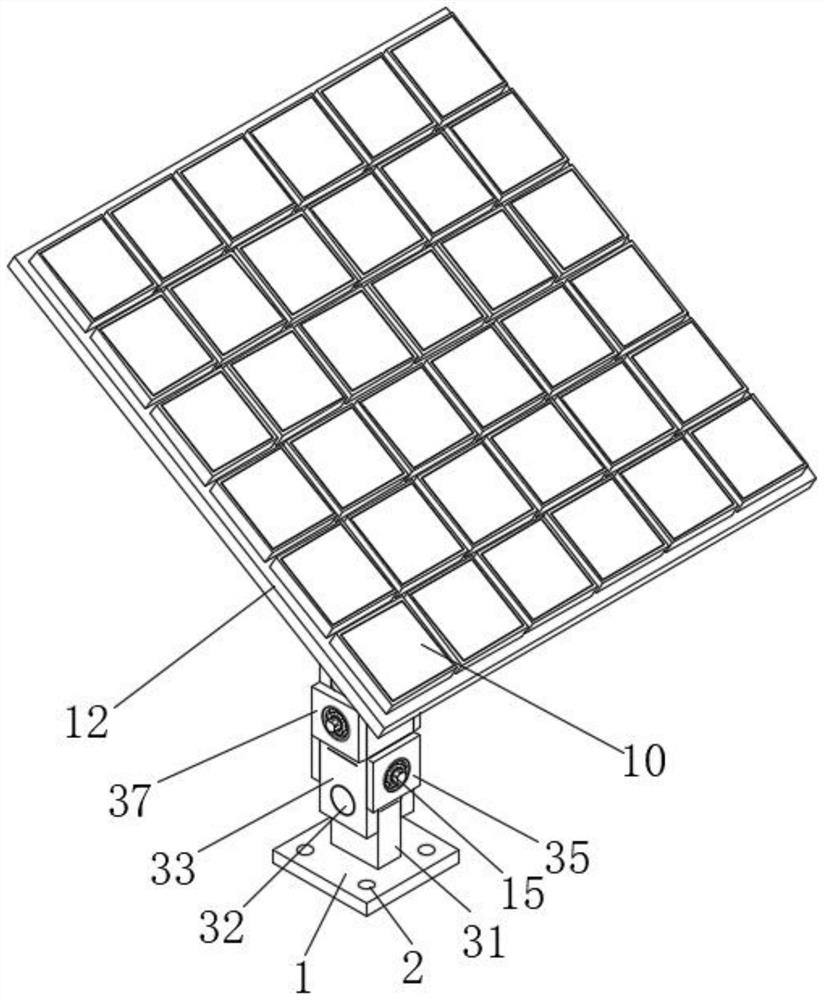

[0025] Embodiment 1: A concentrating photovoltaic power generation matrix that is easy to install, including a fixed plate 1 and an adjustment unit 3;

[0026] Fixing plate 1: mounting holes 2 are opened at the four corners of its upper surface;

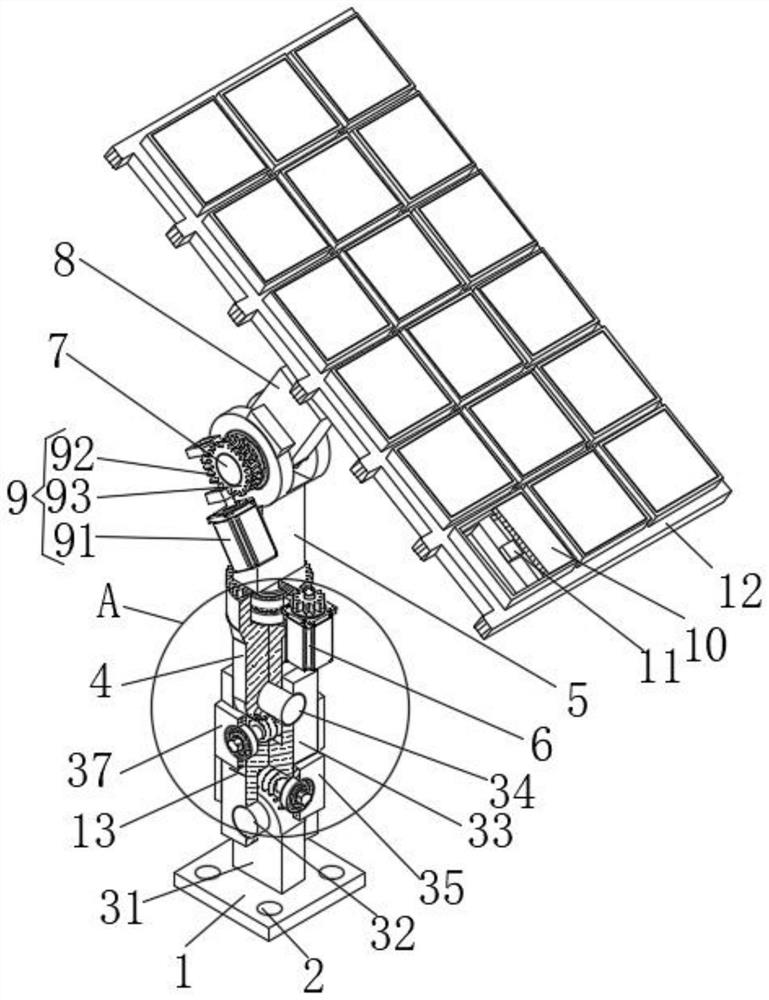

[0027] Adjustment unit 3: set in the middle of the upper surface of the fixed plate 1, the upper end of the adjustment unit 3 is rotatably connected to the support seat 4, the upper end of the support seat 4 is rotatably connected to the rotating seat 5, and the upper end of the rotating seat 5 is rotatably connected to the rotating shaft 3 7. The outer arc surface of the rotating shaft 3 7 is fixedly connected with the inner arc wall at the lower end of the support block 8, the upper end of the support block 8 is provided with a support frame 12, and the upper surface of the support frame 12 is provided with evenly distributed gallium arsenide solar cells 11, The upper surface of the support frame 12 is provided with evenly distribu...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is:

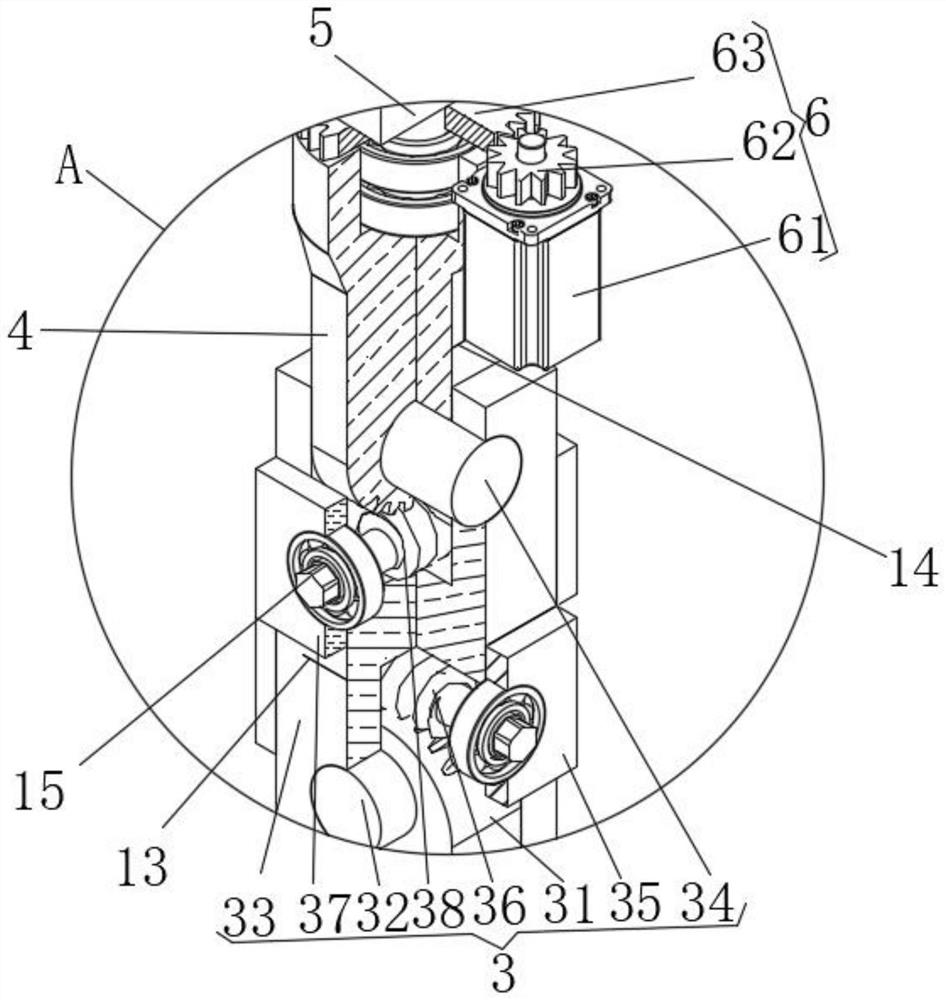

[0032]In the present embodiment, also comprise driving unit one 6, and driving unit one 6 comprises motor one 61, driving gear 62 and driven gear 63, and motor one 61 is arranged on the front side of support seat 4, and the output shaft of motor one 61 is provided with There is a driving gear 62, and a driven gear 63 is provided on the outer arc surface of the shaft at the lower end of the rotating seat 5, and the driven gear 63 is meshed with the driving gear 62, and the input end of the motor one 61 is electrically connected to the output end of the external solar tracking controller. Also comprises drive unit two 9, and drive unit two 9 comprises motor two 91, worm screw three 92 and worm gear 93, and motor two 91 is arranged on the lower end of rotating seat 5 left side, and the upper end of rotating seat 5 left side is rotatably connected with worm screw three. 92, the lower end of the worm three 92 is f...

Embodiment 3

[0035] The difference between this embodiment and Embodiment 1 is:

[0036] In this embodiment, the adjustment unit 3 includes a supporting column 31, a rotating shaft 32, a cross seat 33 and a rotating shaft 2 34, the supporting column 31 is arranged in the middle of the upper surface of the fixed plate 1, and the upper end of the supporting column 31 is rotatably connected with the rotating shaft 1 32, The left and right ends of rotating shaft one 32 are respectively connected with the rotating holes on the left and right sides of the cross seat 33 lower end, and the upper end of cross seat 33 is rotationally connected with rotating shaft two 34, and the outer arc surface at the middle part of rotating shaft two 34 is connected with the inner arc at the support base 4 lower ends. The wall is connected by rotation, and the adjustment unit 3 also includes a vertical plate 35, a worm screw 36, a vertical plate 2 37 and a worm screw 38. There is a worm one 36 connected through b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com