Self-walking pulse reel sprinkling machine and operation method

A technology of self-propelled sprinkler irrigation machine, applied in botany equipment and methods, agriculture, horticulture, etc., can solve the problems of high sprinkling intensity, large nozzle flow rate, and surface runoff, so as to improve spraying uniformity, reduce sprinkling intensity, Effect of reducing nozzle flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

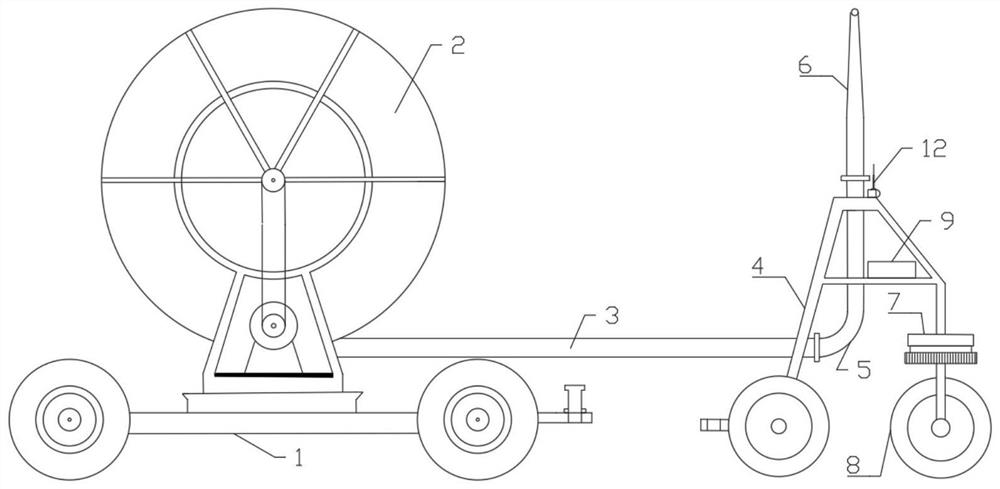

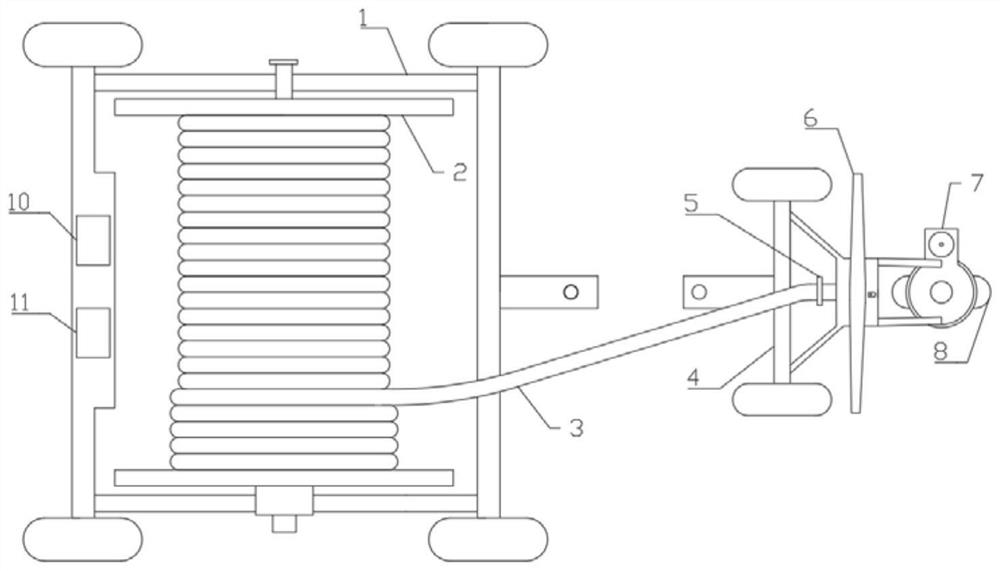

[0039] combined with figure 1 , figure 2 As shown, the self-propelled pulse reel sprinkler irrigation machine includes a reel car 1, a reel 2, a PE reel pipe 3, a sprinkler car 4, a connecting elbow 5, a spraying device 6, a steering device 7, a front wheel 8, a battery a9, Battery b10, controller 11, positioning camera device 12; the reel 2 is installed on the reel car 1, the PE reel pipe 3 is coiled on the reel 2, the spraying device 6 is installed on the nozzle car 4, and is connected through the connecting bend The head 5 communicates with the PE roll pipe 3; the steering device 7 is located above the front wheel 8 of the sprinkler truck 4; the front wheel 8 is located at the front of the sprinkler truck 4 and is the running device of the sprinkler truck 4; the battery a9 is installed on the sprinkler head On the frame of the car 4; the battery b10 and the controller 11 are installed on the frame of the reel car 1, and the positioning camera device 12 is installed on the...

Embodiment 2

[0046] combined with Figure 1 to Figure 9 As shown, the basic structural features and implementation method of Embodiment 2 are similar to Embodiment 1, and the difference from Embodiment 1 lies in the spraying device 6 and the reversing device 6-4.

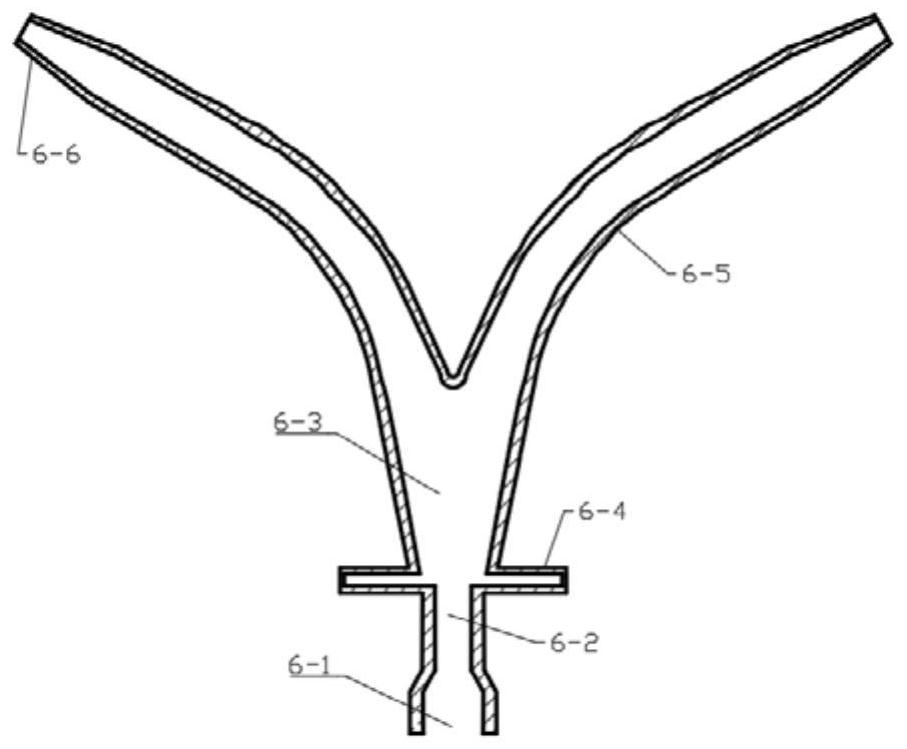

[0047] combined with Figure 4 , Figure 5 As shown, the spraying device 6 is a truss device, including a truss 13, a branch pipe 14, a capillary 15, a small nozzle 16, a capillary jet tee 17, and a branch pipe jet tee 18; the branch pipe 14 is fixed on the truss 13, and the branch pipe The inlet end of the jet tee 18 is connected to the PE roll pipe 3, and the two outlet ends of the branch pipe jet tee 18 are respectively connected to a branch pipe 14; Each outlet end is connected with a capillary 15, and the end of the capillary 15 is connected with a small nozzle 16; the capillary jet tee 17 and the branch pipe jet tee 18 include a water inlet 6-1, a jet pipe 6-2, a jet space 6-3, and a water inlet 6-1. To the device 6-4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com