Gear shaper with adjustable cutter spacing

A gear shaping machine and tool position technology, which is applied to gear cutting machines, gear teeth, mechanical equipment, etc., can solve the problems of inaccurate precision and low efficiency, and achieve the effect of accurate adjustment size, simple structure, and convenient vertical position adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

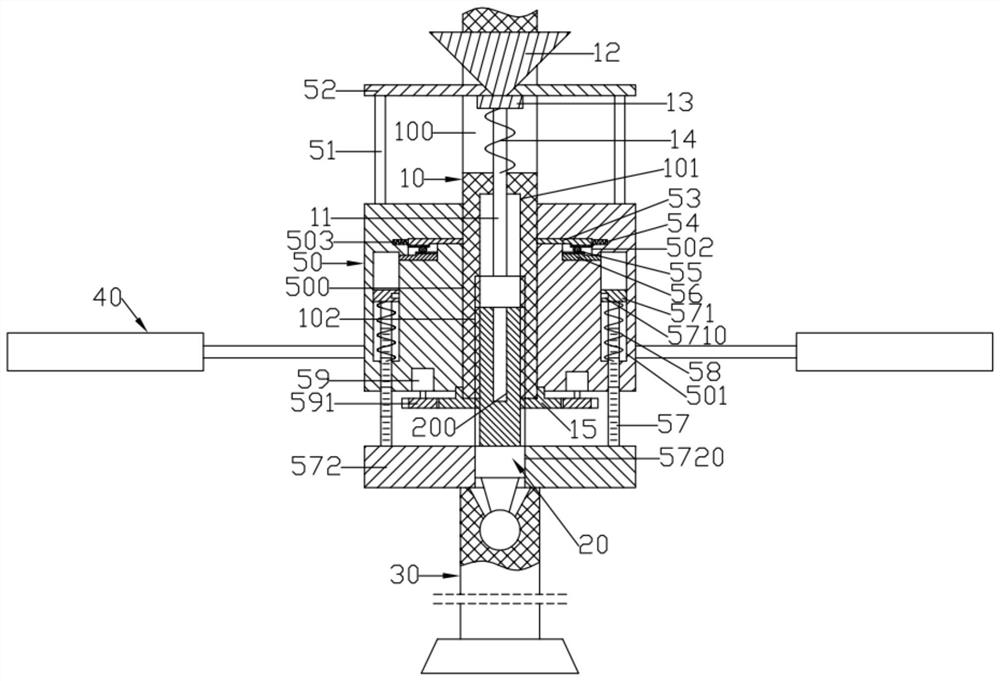

[0015] Such as figure 1 As shown, a gear shaping machine for adjusting the cutter position includes a swing rod 10, a ball tie rod 20, a cutter shaft 30 and a pair of left and right symmetrically arranged cutter position adjustment seats 50; the bottom ball head of the ball pull rod 20 is connected to the cutter shaft 30 and the diameter of the ball tie rod 20 is smaller than the diameter of the cutter shaft 30; the swing rod 10 is fixed on the gear shaping machine frame; the bottom surface of the swing rod 10 is formed with a lifting screw hole 102; Gear 15; the center of the lifting gear 15 is formed with a driving threaded hole; the upper part of the ball tie rod 20 is screwed into the lifting threaded hole 102 and the driving threaded hole; and the right side; the end faces of a pair of knife position adjustment seats 50 that are close to each other are respectively formed with semi-cylindrical groove-shaped upper slots 500 with upper and lower openings; the diameter of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com