Polishing shaft for flexibly cleaning casting blank

A technology for cleaning castings and grinding shafts, applied in the field of grinding shafts, can solve problems such as incomplete function of parts, damaged parts, unclean grinding of burrs, etc., and achieve the effect of ensuring air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

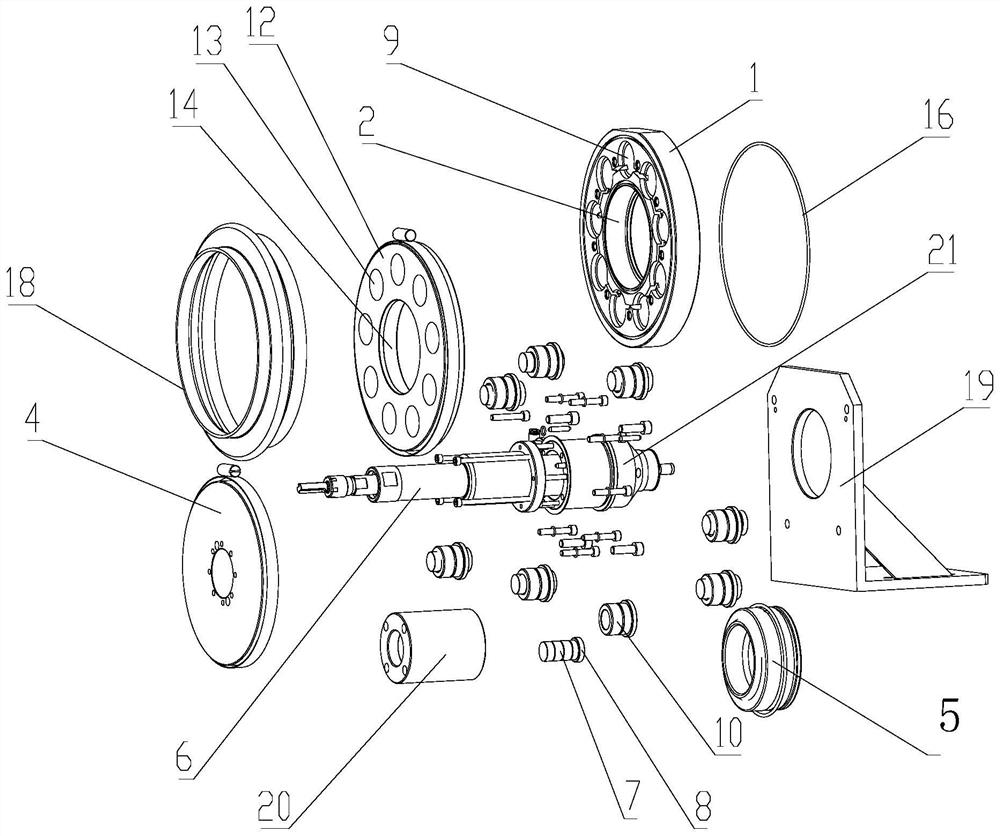

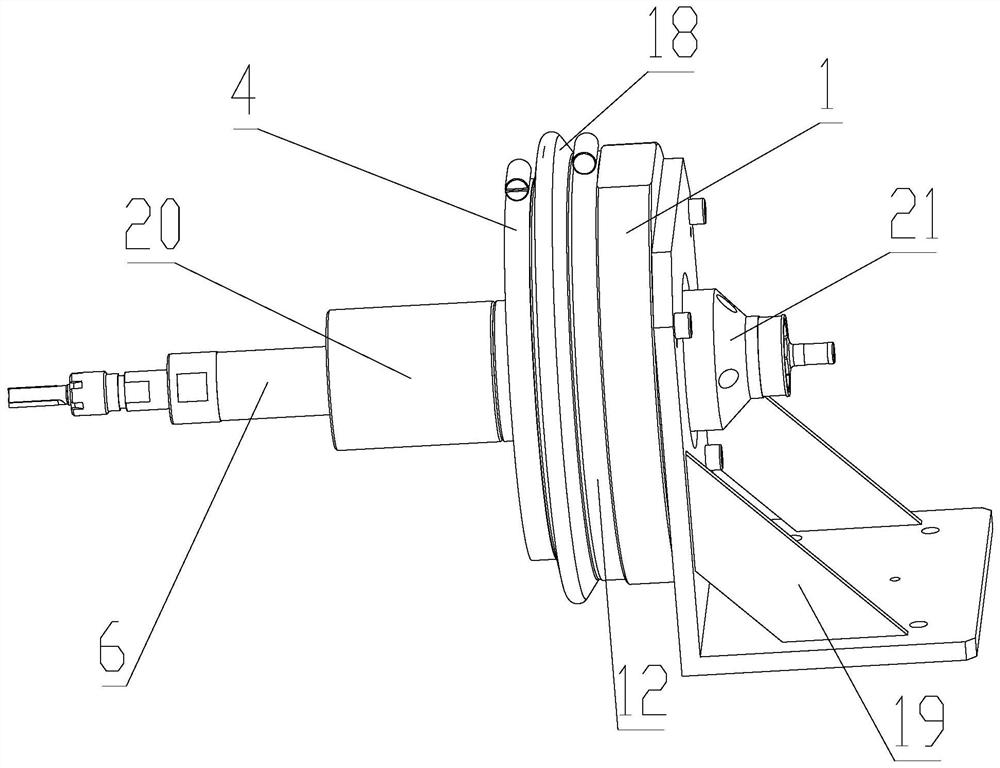

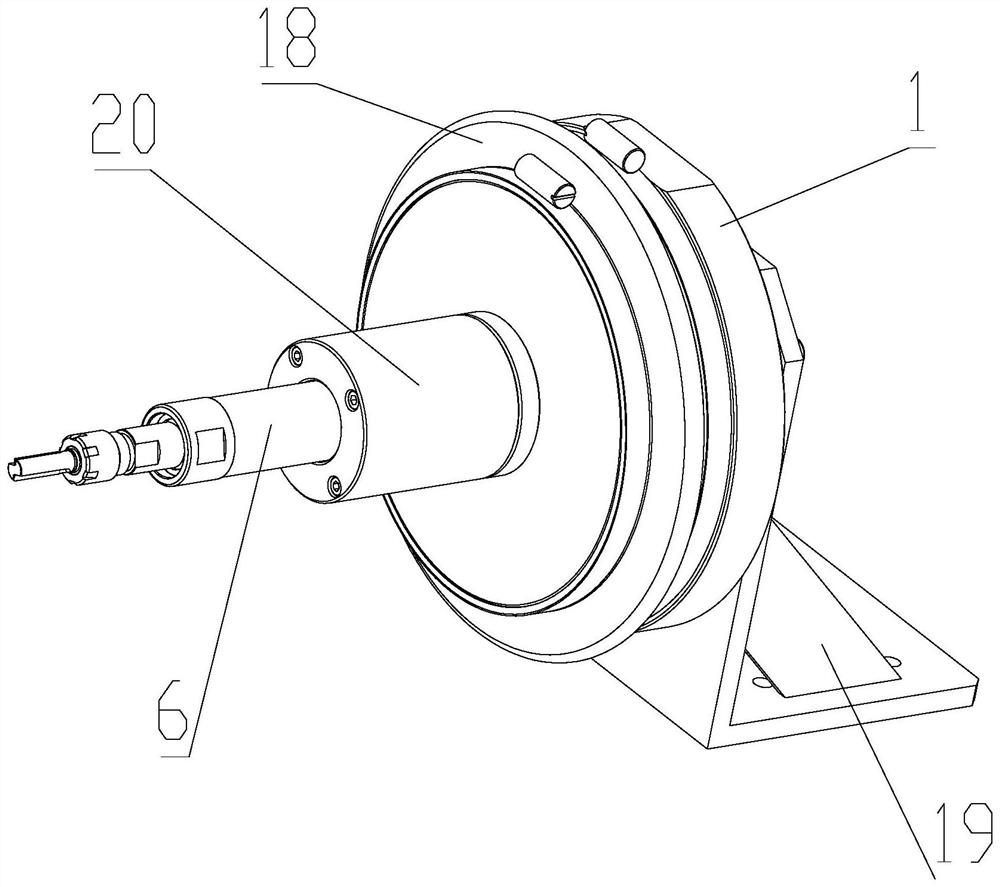

[0025] see Figure 1-6 , a grinding shaft for flexible cleaning of casting blanks, comprising a base plate 1, the base plate 1 is provided with an installation channel 2 that runs through the front and back of the base plate 1, and the base plate 1 is equidistantly arranged around the circumference of the installation channel 2 There are several identical pneumatic telescopic rods, the telescopic direction of the pneumatic telescopic rods faces the front of the base plate 1, and the top ends of all the pneumatic telescopic rods are jointly connected to a floating plate 4 through the first joint bearing 3, and the installation channel 2 is connected between the two ends of the air motor 6 through the second joint bearing 5, the output end of the air motor 6 faces the front of the base plate 1, the air motor 6 runs through the floating plate 4 and the air motor 6 The two ends are fixedly connected to the center of the floating plate 4, and the cylinders of all the pneumatic expa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com