Hanging rail type inspection robot

An inspection robot and rail-mounted technology, applied in the field of inspection robots, can solve the problems of noise, affecting inspection work, and inconvenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The embodiment of the invention discloses a rail-mounted inspection robot.

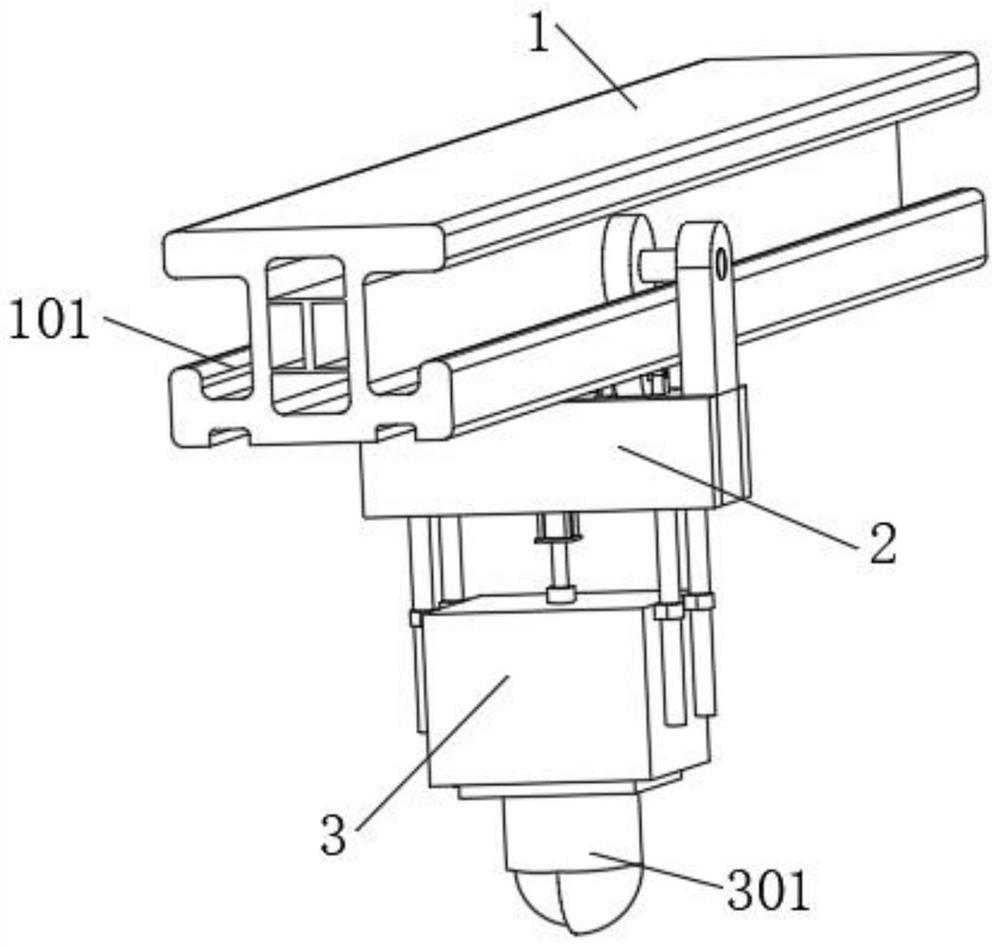

[0065] Please refer to the attached Figure 1-4 ,include:

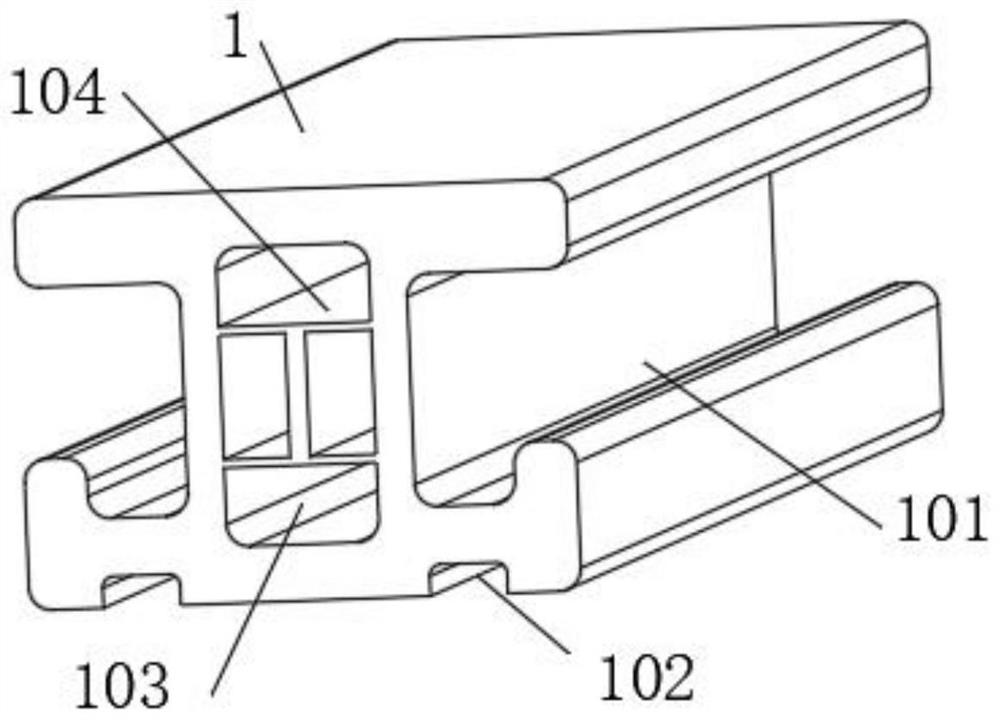

[0066] The track main body 1 has positioning grooves 101 on both sides of the track main body 1, and two slide grooves 102 are symmetrically opened on the lower surface of the track main body 1;

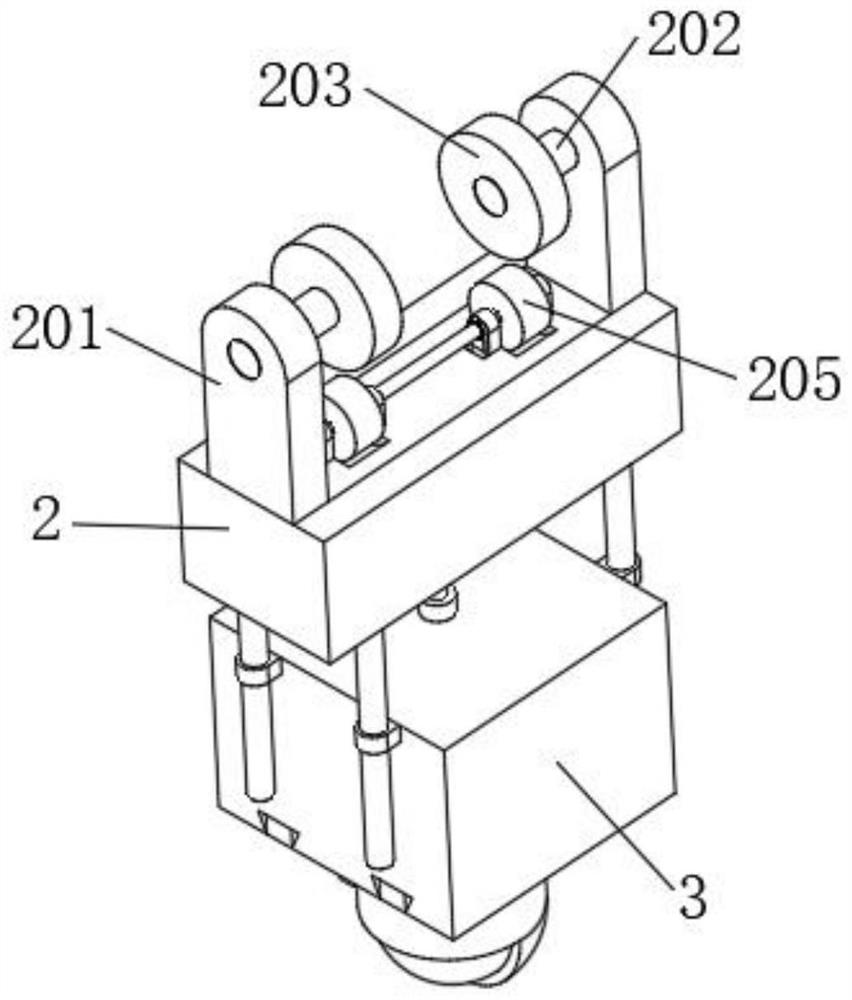

[0067]The fixed seat 2, the fixed seat 2 is arranged under the track main body 1, and the top of the fixed seat 2 is symmetrically fixedly connected with two support blocks 201, and the opposite sides of the two support blocks 201 are respectively in contact with the two sides of the track main body 1 without squeezing and the tops of the two supporting blocks 201 are fixedly connected with the fixed shaft 202, and the ends of the fixed shaft 202 extend toward the inside of the positioning groove 101, and are fixedly connected with the positioning wheel 203, and the two positioning wheels 203 are respectively connected with the two The inne...

Embodiment 2

[0076] The embodiment of the invention discloses a rail-mounted inspection robot.

[0077] Please refer to attached Figure 1-4 ,include:

[0078] The track main body 1 has positioning grooves 101 on both sides of the track main body 1, and two slide grooves 102 are symmetrically opened on the lower surface of the track main body 1;

[0079] The fixed seat 2, the fixed seat 2 is arranged under the track main body 1, and the top of the fixed seat 2 is symmetrically fixedly connected with two support blocks 201, and the opposite sides of the two support blocks 201 are respectively in contact with the two sides of the track main body 1 without squeezing and the tops of the two supporting blocks 201 are fixedly connected with the fixed shaft 202, and the ends of the fixed shaft 202 extend toward the inside of the positioning groove 101, and are fixedly connected with the positioning wheel 203, and the two positioning wheels 203 are respectively connected with the two The inner b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com