Machine for packaging standardized dishes

A technology of machinery and dishes, applied in the field of automatic packaging of standardized dishes, can solve problems such as uneven soup ingredients, unsuitable for early separation, changes in taste and quality, etc., to achieve uniform and efficient packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

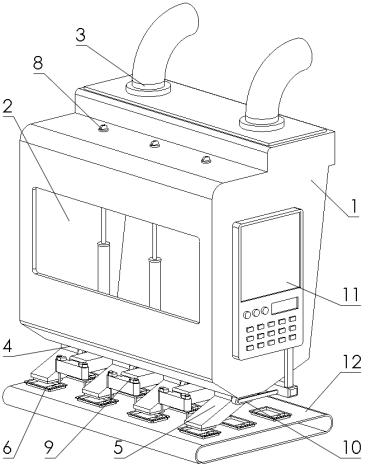

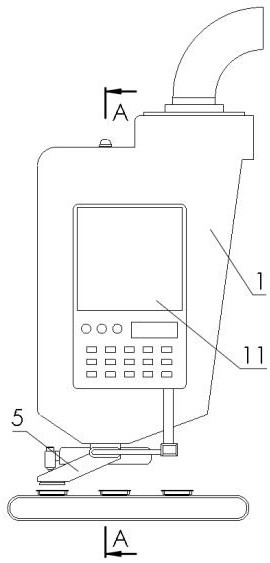

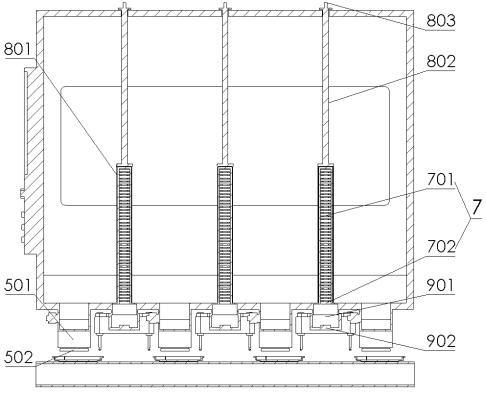

[0043]A machine for packaging standardized dishes, which includes a machine body 1 arranged above a conveyor belt 12 and an operating table 11 arranged on one side of the machine body 1. A feeding bin 2 is arranged inside the body 1; mouth 3, the bottom is provided with a vegetable outlet 4; the lower part of the body 1 is provided with a vegetable distributing mechanism 5 through the vegetable outlet 4; A diversion control part 8 is provided; the vegetable soup diversion mechanism 7 is composed of a soup filtering screen 701 arranged in the feeding bin 2 and a soup outlet 702 arranged at the bottom of the feeding bin 2; the soup outlet 702 is connected with the cloth soup The mechanisms 9 are connected; the vegetable outlet 4 is provided with an electric partition 10 for controlling its on-off;

Embodiment 2

[0045] As a further optimization of the above-mentioned embodiment: a machine for packaging standardized dishes, it includes a machine body 1 arranged above the conveyor belt 12 and an operating table 11 arranged on one side of the machine body 1, and a feeding bin 2 is arranged in the body 1; The top of the feeding bin 2 is provided with a feeding port 3, and the bottom is provided with a vegetable outlet 4; the lower part of the body 1 is provided with a vegetable distributing mechanism 5 through the vegetable outlet 4; the feeding bin 2 is provided with a vegetable soup diverting mechanism 7, The vegetable soup diversion mechanism 7 is provided with a diversion control member 8; the vegetable soup diversion mechanism 7 is composed of a soup filtering screen 701 arranged in the feeding bin 2 and a soup outlet 702 arranged at the bottom of the feeding bin 2; The soup outlet 702 is connected with the soup making mechanism 9; the vegetable outlet 4 is provided with an electric p...

Embodiment 3

[0047] As a further optimization of the above-mentioned embodiment: a machine for packaging standardized dishes, it includes a machine body 1 arranged above the conveyor belt 12 and an operating table 11 arranged on one side of the machine body 1, and a feeding bin 2 is arranged in the body 1; The top of the feeding bin 2 is provided with a feeding port 3, and the bottom is provided with a vegetable outlet 4; the lower part of the body 1 is provided with a vegetable distributing mechanism 5 through the vegetable outlet 4; the feeding bin 2 is provided with a vegetable soup diverting mechanism 7, The vegetable soup diversion mechanism 7 is provided with a diversion control member 8; the vegetable soup diversion mechanism 7 is composed of a soup filtering screen 701 arranged in the feeding bin 2 and a soup outlet 702 arranged at the bottom of the feeding bin 2; The soup outlet 702 is connected with the soup making mechanism 9; the vegetable outlet 4 is provided with an electric p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com