Material moving mechanism applied to automatic assembly line

A material-moving mechanism and assembly line technology, which is applied in the direction of conveyor objects, transportation and packaging, chute, etc., to avoid mechanical impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

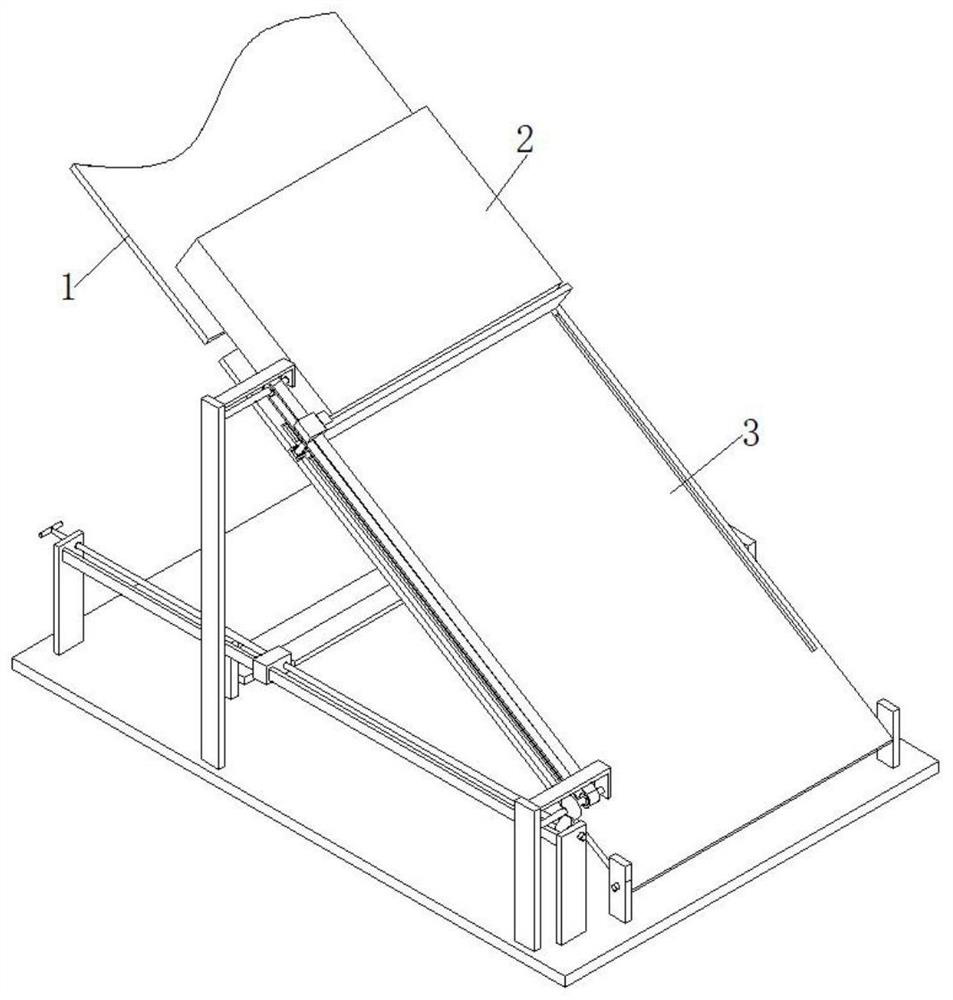

[0032] see figure 1 As shown, the present invention is a material shifting mechanism applied to an automated assembly line, including an automated assembly line, an inclined plate 1 and a workpiece 2 are included on the automated assembly line, a material transfer mechanism 3 is arranged on the automated assembly line, and the material transfer mechanism 3 is located on an inclined At one end of the plate 1, the material shifting mechanism 3 cooperates with the inclined plate 1 to realize the movement of the workpiece 2 from top to bottom.

Embodiment 2

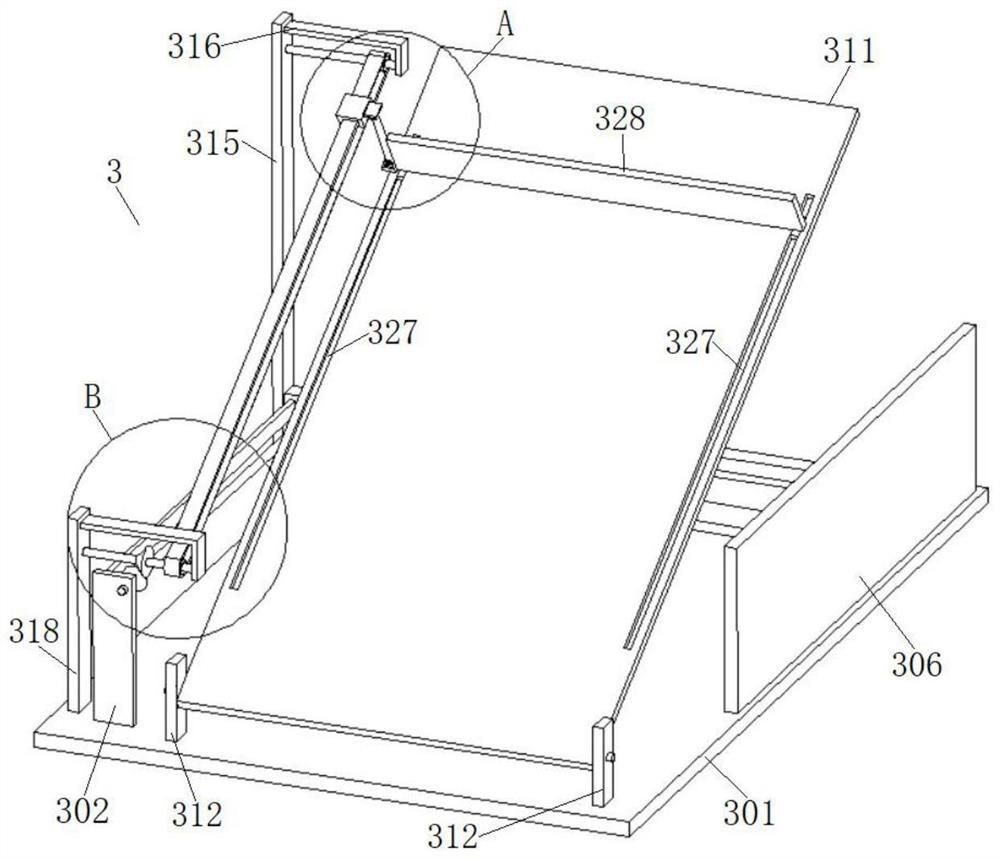

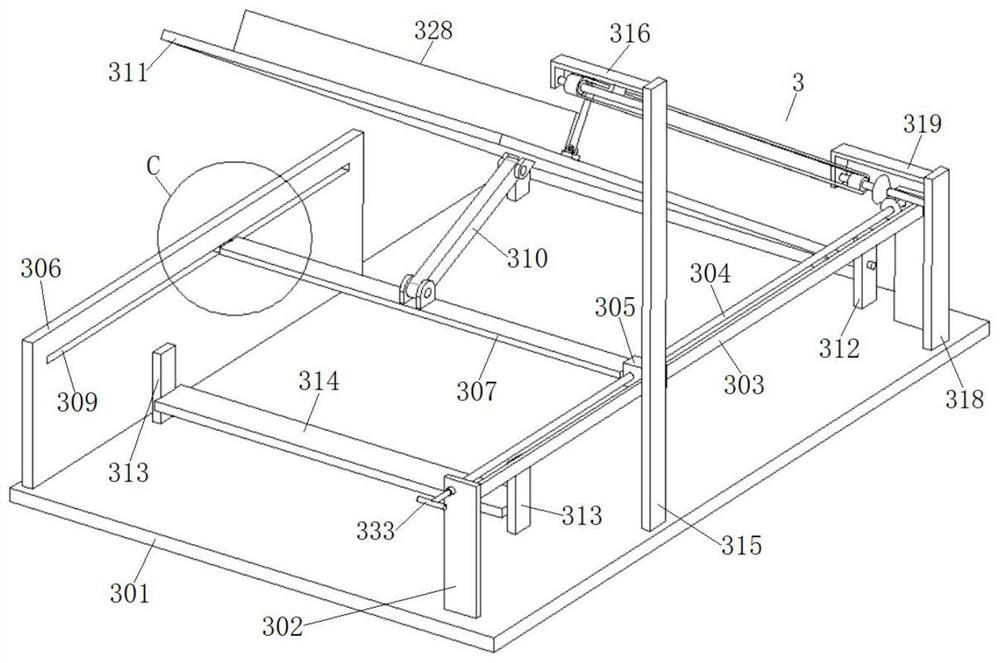

[0034] Based on the technical solution described in the first embodiment above. see Figure 2-6 As shown, the material transfer mechanism 3 includes a machine platform 301 , a connecting push rod 310 , a movable plate 311 , a sliding plate 328 and a telescopic rod 332 . The upper surface of the machine table 301 is provided with a pair of first vertical support plates 302, a horizontal sliding plate 303 is fixedly connected between the pair of first vertical support plates 302, and a horizontal sliding plate 303 is rotatably connected between the pair of first vertical support plates 302. Screw mandrel 304. A first slide block 305 is slidably installed on the transverse slide plate 303, and a threaded hole is provided on the first slide block 305, and the transverse screw rod 304 is meshed with the threaded hole on the first slide block 305, and the transverse screw rod 304 drives the first slide block 305 slides on the horizontal slide plate 303.

[0035] The upper surface...

Embodiment 3

[0042] Based on the technical solution described in the second embodiment above. see image 3 As shown, an elastic pad can be provided on the transverse support plate 314, so that the movable plate 311 is turned from an inclined state to a horizontal state and rests on the elastic pad, so as to avoid mechanical impact on the movable plate 311. One end of the horizontal screw rod 304 is provided with a handle bar 333, the handle bar 333 is a T-shaped structure, by rotating the handle bar 333, the upper surface of the movable plate 311 is coplanar with the upper surface of the inclined plate 1, so that the workpiece 2 can move smoothly from the inclined plate 1 slide onto the movable plate 311.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com