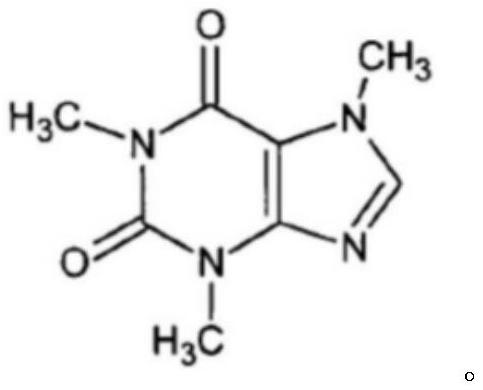

Synthetic method of caffeine

A synthetic method and caffeine technology, applied in the direction of organic chemistry, etc., can solve the problems of occupying a large reactor, potential safety hazards, large heat collection, etc., and achieve the effects of high efficiency in the production process, high safety assurance, and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

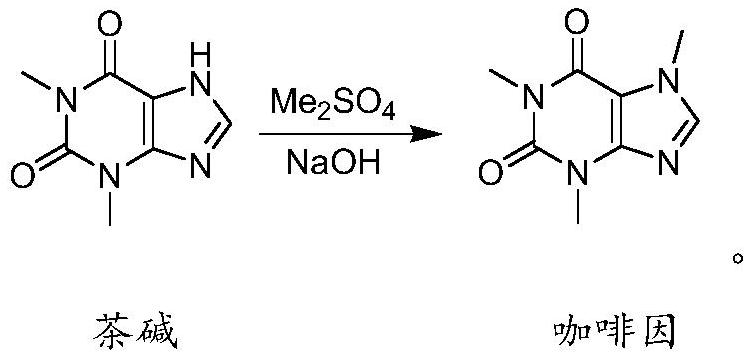

Method used

Image

Examples

Embodiment 1

[0046] At room temperature, add 8g NaOH to 2000mL water, add 36g theophylline to it and stir evenly to make liquid A, add 50g dimethyl sulfate to 1630mL water to make liquid B, set the temperature of the reaction module in the reaction zone to 20°C, and use Feed pump A and feed pump B control liquid A and liquid B at a certain flow rate (keep the molar ratio of theophylline to dimethyl sulfate 1:1) at the same time into the first microchannel reaction module for mixing and reaction, and then continue Feed into 8 microchannel reaction modules connected in series to react, control the flow rate of feed pump A to be 26.2g / min, control the flow rate of feed pump B to be 10.7g / min, when there is material flow out from the outlet end of the microchannel system Finally, after waiting for the pH value of the effluent to be stable, the effluent was continuously collected for 12 minutes, combined, cooled in an ice bath for crystallization, filtered, and dried. The yield was 82.6%, and th...

Embodiment 2

[0048] At room temperature, add 16g NaOH to 2000mL water, add 36g theophylline to it and stir evenly to make liquid A, add 63g dimethyl sulfate to 2460mL tetrahydrofuran to make liquid B, set the temperature of the reaction module in the reaction zone to 50°C, respectively With feed pump A and feed pump B, A liquid and B liquid control certain flow velocity (keep theophylline and dimethyl sulfate molar ratio 1: 2.5) pass in the 1st microchannel reaction module simultaneously and mix and react, then Continue to pass into 7 microchannel reaction modules connected in series successively to react, control the flow velocity of feed pump A to be 20.9g / min, control the flow velocity of feed pump B to be 22.8g / min, when there is material at the outlet end of the microchannel system After the outflow, wait for the pH value of the effluent to be stable, collect the effluent continuously for 9 minutes, combine the effluent, concentrate under reduced pressure and evaporate the organic solv...

Embodiment 3

[0050] At room temperature, add 70g NaOH to 2000mL water, add 86g theophylline to it and stir evenly to make liquid A, add 378g dimethyl sulfate to 1420mL toluene to make liquid B, set the temperature of the reaction module in the reaction zone to 55°C, respectively With feed pump A and feed pump B, liquid A and liquid B are controlled to a certain flow rate (keep theophylline and dimethyl sulfate molar ratio 1:3) and pass into the first microchannel reaction module to mix and react at the same time, then Continue to pass into 6 microchannel reaction modules connected in series successively to react, control the flow velocity of feed pump A to be 25.4g / min, control the flow velocity of feed pump B to be 9.1g / min, when there is material at the outlet end of the microchannel system After the outflow, wait for the pH value of the effluent to be stable, collect the effluent continuously for 10 minutes, combine the effluent, concentrate under reduced pressure and evaporate the organ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com