Double-flow feeding method for vanadium slag pressure leaching reaction kettle

A technology of pressure leaching and reaction kettle, which is applied in the field of vanadium chemical industry and metallurgy, can solve the problems of high energy consumption and high roasting temperature, and achieve the effects of improving heat exchange efficiency, reducing preheating costs and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

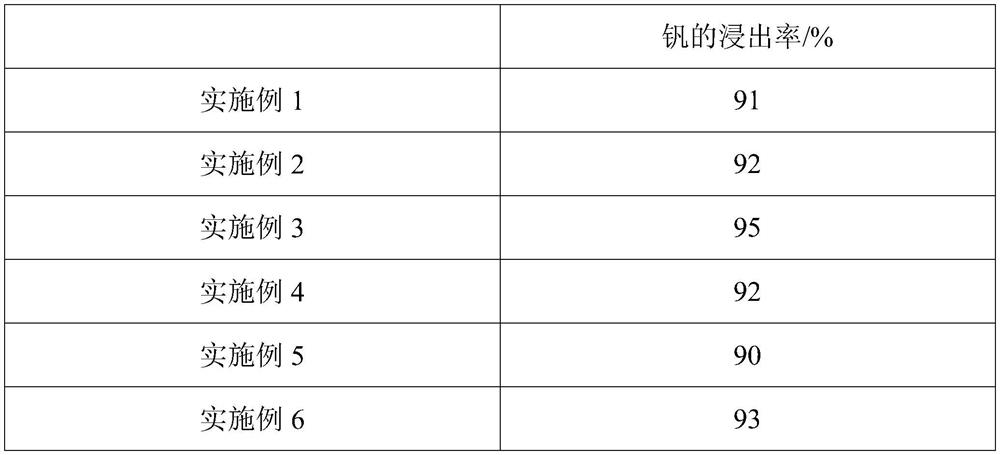

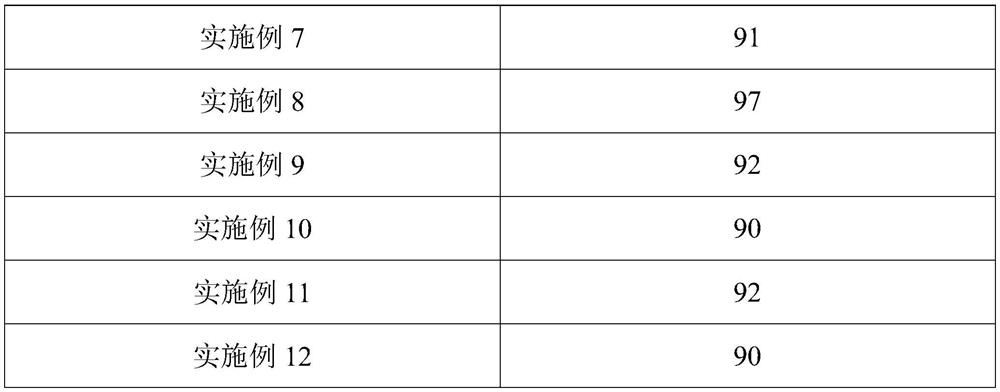

Examples

Embodiment 1

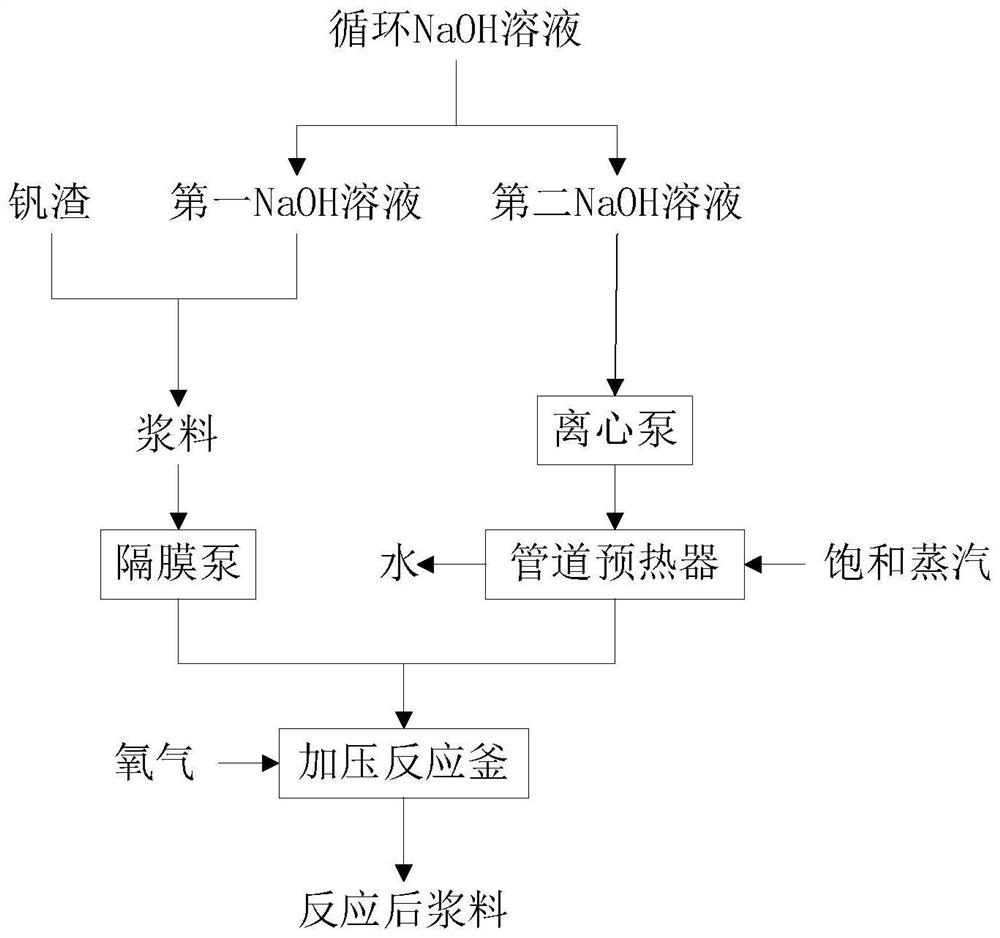

[0056] This embodiment provides a method for dual-flow feeding of vanadium slag pressure leaching reactor, the process flow of the method is as follows figure 1 shown.

[0057] The method comprises the steps of:

[0058] Provide an initial temperature of 90°C and a concentration of 45wt% evaporated circulating NaOH solution, which is divided into A shares and B shares, wherein A shares are the first NaOH solution, and B shares are the second NaOH solution;

[0059] (1) The first NaOH solution is mixed with the vanadium slag that passes through a 200 mesh sieve and the proportion is 80wt%, to obtain a slurry with a liquid-solid ratio of 1.6:1;

[0060] (2) Preheating the second NaOH solution to 180° C. with a pipeline preheater, wherein the heating medium is saturated steam with a pressure of 3.0 MPa;

[0061] Then, the slurry obtained in step (1) is transported to the reactor by a diaphragm pump, and the preheated second NaOH solution is transported to the pressurized reacto...

Embodiment 2

[0063] This embodiment provides a method for dual-flow feeding of a vanadium slag pressure leaching reactor, the method comprising the following steps:

[0064] Provide the freshly prepared NaOH solution that initial temperature is 86 ℃, concentration is 48wt%, is divided into A share and B share, wherein, A share is the first NaOH solution, B share is the second NaOH solution;

[0065] (1) The first NaOH solution is mixed with the vanadium slag that passes through a 200 mesh sieve and the particle ratio is 84wt%, to obtain a slurry with a liquid-solid ratio of 2.0:1;

[0066] (2) Preheating the second NaOH solution to 210° C. with a pipeline preheater, wherein the heating medium is saturated steam with a pressure of 3.6 MPa;

[0067] Then, the slurry obtained in step (1) is transported to the reactor by a diaphragm pump, and the preheated second NaOH solution is transported to the pressurized reactor by a centrifugal pump whose impeller material is a Ni-Cr alloy. The additio...

Embodiment 3

[0069] This embodiment provides a method for dual-flow feeding of a vanadium slag pressure leaching reactor, the method comprising the following steps:

[0070] Provide an initial temperature of 80°C and a concentration of 50wt% evaporated circulating NaOH solution, which is divided into A shares and B shares, wherein A shares are the first NaOH solution, and B shares are the second NaOH solution;

[0071] (1) The first NaOH solution is mixed with the vanadium slag that passes through a 200 mesh sieve and the particle ratio is 86wt%, to obtain a slurry with a liquid-solid ratio of 1.8:1;

[0072] (2) Preheating the second NaOH solution to 220° C. with a pipeline preheater, wherein the heating medium is saturated steam with a pressure of 3.7 MPa;

[0073] Then, the slurry obtained in step (1) is transported to the reactor by a diaphragm pump, and the preheated second NaOH solution is transported to the pressurized reaction tank by a centrifugal pump whose impeller material is N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com