Preparation method of composite filament

A technology of composite yarn and filament, which is applied in the field of polyester fiber, can solve problems such as difficulty in grid-connection and joint stock, dependence on matching ratio, weak three-dimensional layering, etc., and achieve the effect of improving the aurora effect, strong three-dimensional layering, and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

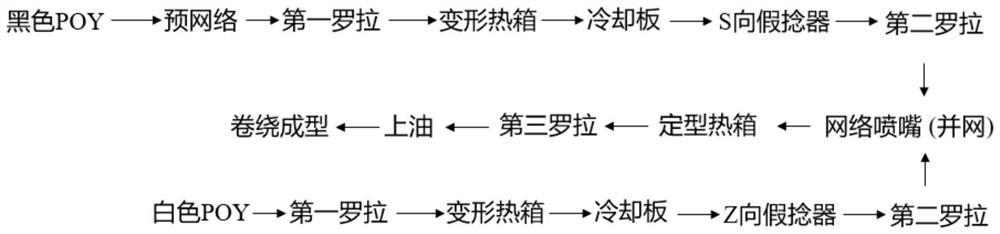

[0037] A kind of preparation method of composite yarn, such as figure 1 As shown, the specific steps are as follows:

[0038] (1) Preparation of low elastic yarn A and low elastic yarn B;

[0039] The preparation process of low elastic yarn A is as follows: After the raw material is pre-networked, it is deformed by the first roller and then passed through the deformation heating box. Low elastic yarn A through pre-network; wherein, the pre-network pressure is 1.6MPa; the raw material is polyester POY yarn, the color is black, the fineness of the raw material is 185dtex, and the number of single filaments is 192f;

[0040] The preparation process of the low elastic yarn B is as follows: the raw material is directly passed through the first roller and then deformed through the deformation heat box, and after leaving the deformation box, it is cooled by the cooling plate for false twisting, and then processed by the second roller to obtain a non-pre-networked yarn. Low elastic ...

Embodiment 2

[0061] A kind of preparation method of composite silk, concrete steps are as follows:

[0062] (1) Preparation of low elastic yarn A and low elastic yarn B;

[0063] The preparation process of low elastic yarn A is as follows: After the raw material is pre-networked, it is deformed by the first roller and then passed through the deformation heating box. Low elastic yarn A through pre-network; wherein, the pre-network pressure is 1.2MPa; the raw material is polyester POY yarn, the color is black, the fineness of the raw material is 88dtex, and the number of single filaments is 72f;

[0064] The preparation process of the low elastic yarn B is as follows: the raw material is directly passed through the first roller and then deformed through the deformation heat box, and after leaving the deformation box, it is cooled by the cooling plate for false twisting, and then processed by the second roller to obtain a non-pre-networked yarn. Low stretch yarn B; the raw material is polyes...

Embodiment 3

[0069] A kind of preparation method of composite silk, concrete steps are as follows:

[0070] (1) Preparation of low elastic yarn A and low elastic yarn B;

[0071] The preparation process of low elastic yarn A is as follows: After the raw material is pre-networked, it is deformed by the first roller and then passed through the deformation heating box. Low elastic yarn A through pre-network; wherein, the pre-network pressure is 1MPa; the raw material is polyester POY yarn, the color is black, the fineness of the raw material is 30dtex, and the number of single filaments is 12f;

[0072] The preparation process of the low elastic yarn B is as follows: the raw material is directly passed through the first roller and then deformed through the deformation heat box, and after leaving the deformation box, it is cooled by the cooling plate for false twisting, and then processed by the second roller to obtain a non-pre-networked yarn. Low elastic yarn B; the raw material is polyeste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com