Washing machine

A washing machine and air intake channel technology, applied in the field of washing machines, can solve the problems of single water flow, wear, and entanglement of clothes, and achieve the effects of alleviating entanglement of clothes and serious wear and tear of clothes, reducing design and manufacturing costs, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

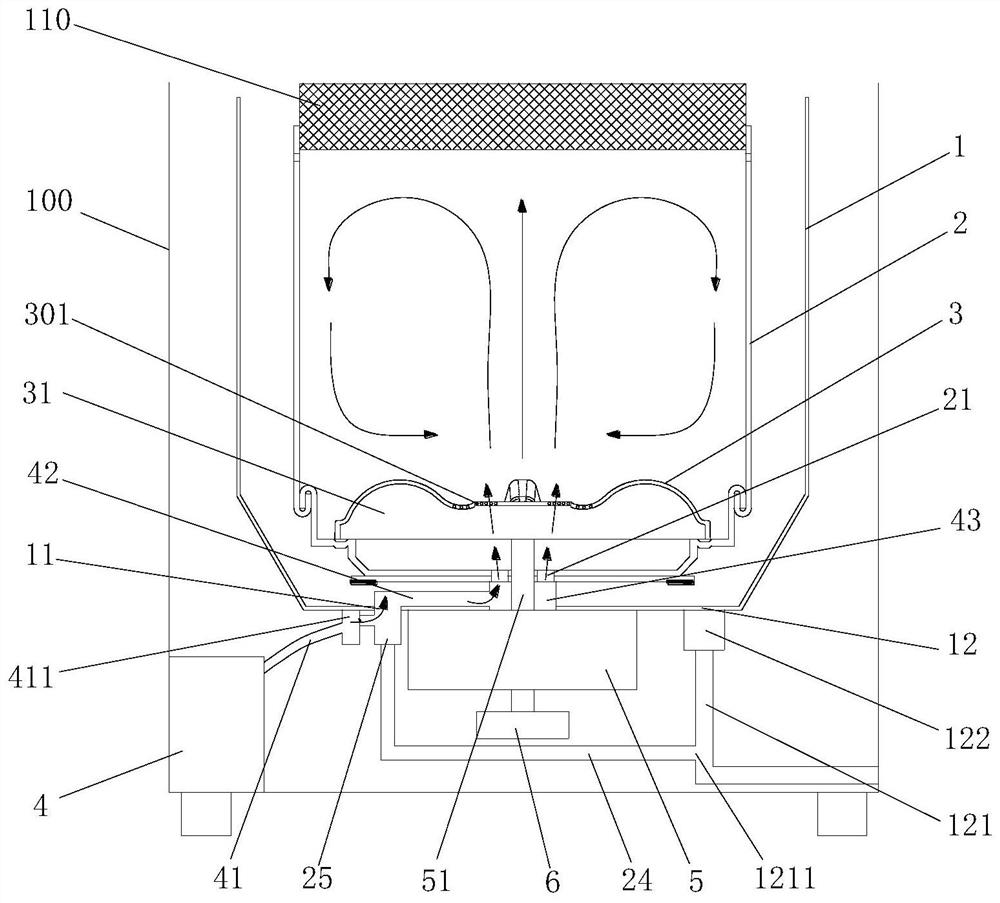

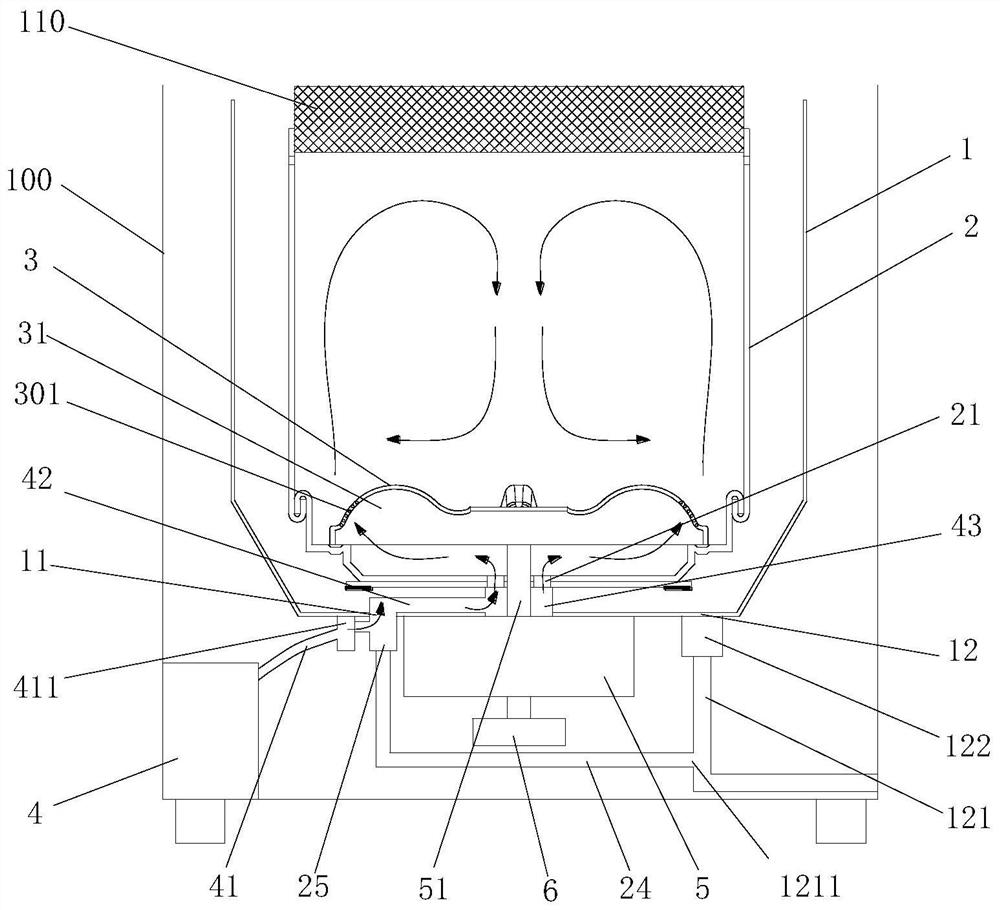

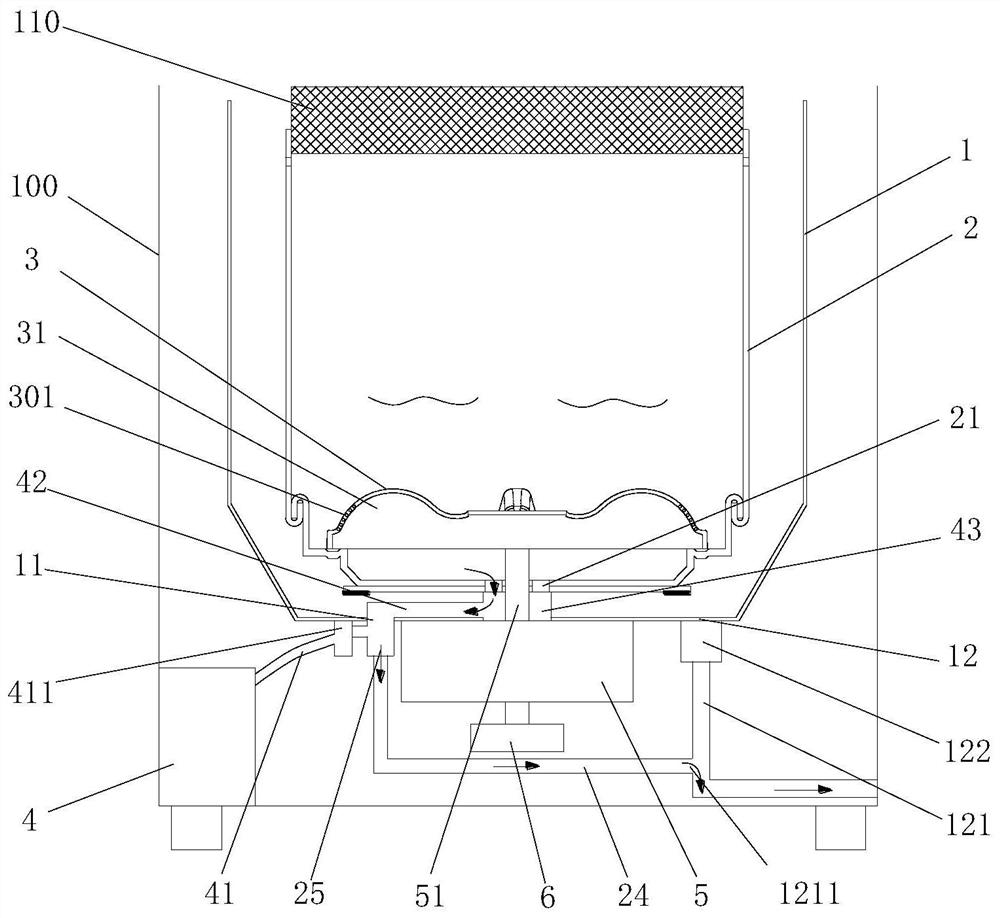

[0077] Specifically, the structure of the washing machine provided in this example is introduced in detail through the following two implementation modes:

[0078] The first implementation mode:

[0079] This embodiment mainly introduces that the inlet end of the second air intake passage 42 is connected to the first air intake passage 41 through the conduction port 11 , so as to realize the communication between the air supply device 4 and the inner tub 2 .

[0080] Specifically, a first connection port is opened on the peripheral side wall of the annular communication part, and the second air intake passage 42 includes a first horizontal pipe arranged between the first connection port and the conduction port 11 , The first horizontal pipe is located inside the tub 1, one end of the first horizontal pipe is connected to the first connection port and the other end extends vertically downward to form a first vertical pipe; the first vertical pipe is formed by the The conductio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com