Novel showcase sealing structure

A sealing structure and a new type of technology, which can be used in the sealing of engines, connecting components, display cabinets, etc., can solve the problems of large seams, poor air tightness, and sealant residue in display cabinets, and increase the sealing contact area and expand the contact area. Neat and beautiful effect of area and appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

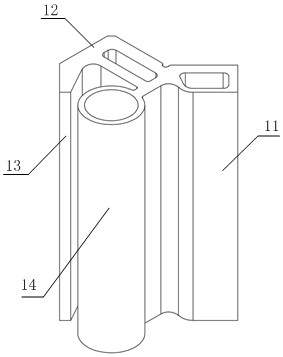

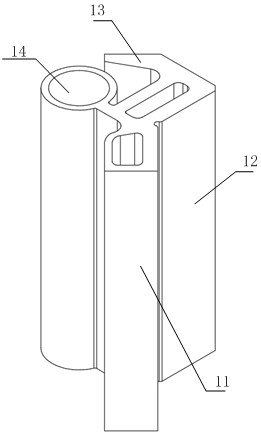

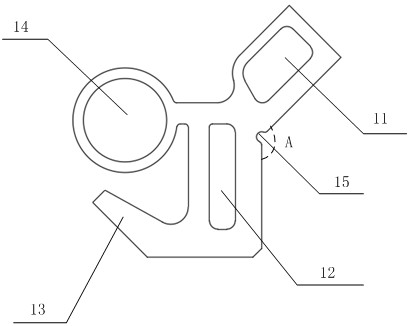

[0020] like figure 1 , figure 2 shown, and refer to image 3 and Figure 4 ; This embodiment is mainly suitable for connecting exhibition appliances such as glass and glass sandwich panels.

[0021] The novel showcase sealing structure of the embodiment of the present invention includes: a first sealing strip 11 and a second sealing strip 12; the first sealing strip 11 and the second sealing strip 12 are generally made of silica gel.

[0022] Both the first sealing strip 11 and the second sealing strip 12 are hollow rectangular tubular structures; the second sealing strip 12 has a first end and a second end, and the first end and the second end correspond to each other, and The farthest distance is located on the diagonal of the rectangular tubular structure. There is an angle A greater than 90 degrees between the first end and the first sealing strip 11; the angle A is used to abut against the chamfer of the connected glass, so that the first sealing strip and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com