Efficient guitar fingerboard bonding device and use method

A technology of bonding device and guitar, which is applied to guitars, instruments, stringed instruments, etc., can solve the problems of long bonding time, difficult operation and low precision, and achieve the effects of short bonding time, safe operation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in combination with specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

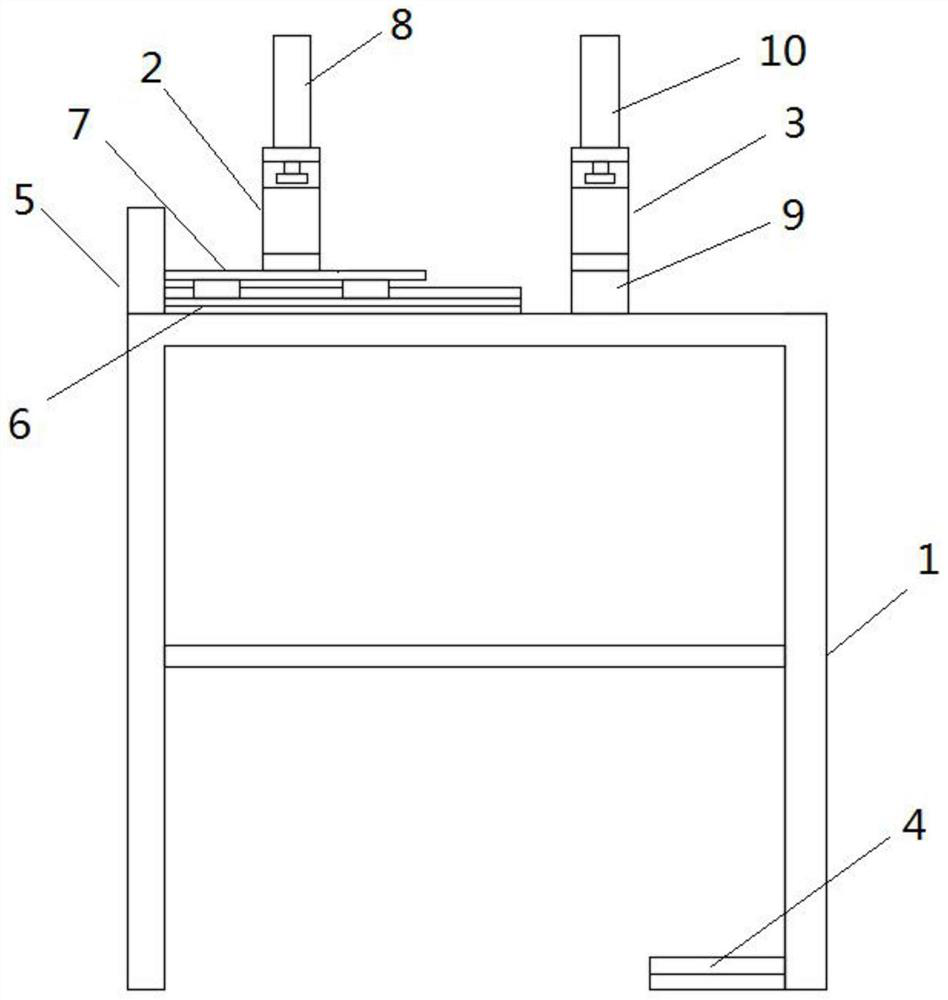

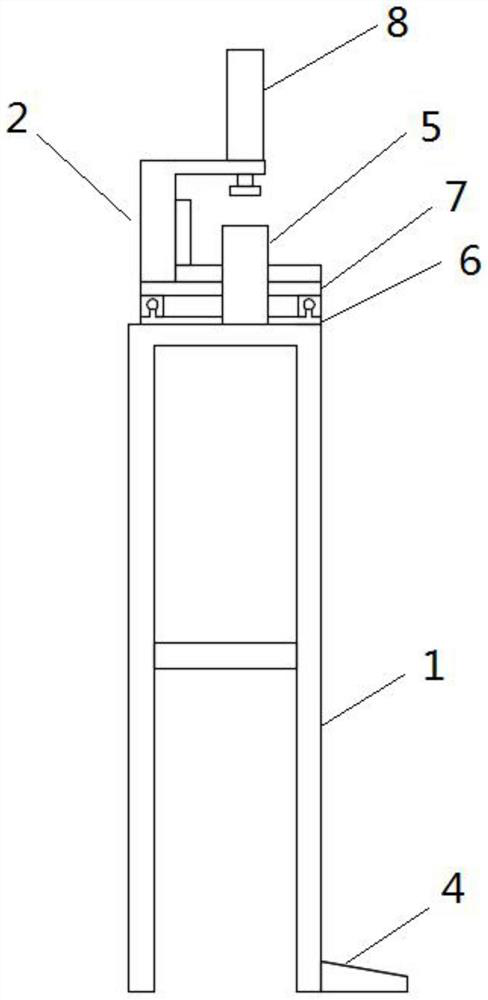

[0018] Such as Figure 1~2 Shown, described a kind of high-efficiency guitar fingerboard bonding device is characterized in that:

[0019] The fingerboard bonding device includes a support frame 1, a mobile locking assembly 2, a fixed locking assembly 3, and an air valve pedal 4. The mobile locking assembly 2 is distributed on the left part of the support frame 1, and the left part of the support frame 1 There is a limit plate 5 at the bottom, which is used to limit the movement of the locking assembly 2 to prevent it from slipping; the fixed locking assembly 3 is distributed on the right part of the support frame 1; the valve pedal 4 is distributed at the bottom of the support frame 1 for Control the mobile cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com