Heat-dissipation low-voltage switch cabinet

A low-voltage switchgear and cabinet body technology, applied in the field of low-voltage switchgear, can solve the problems of self-ignition of the electric cabinet, affecting the circuit connection in the electric cabinet, danger, etc., and achieve the effect of accelerating the exchange speed and improving the heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

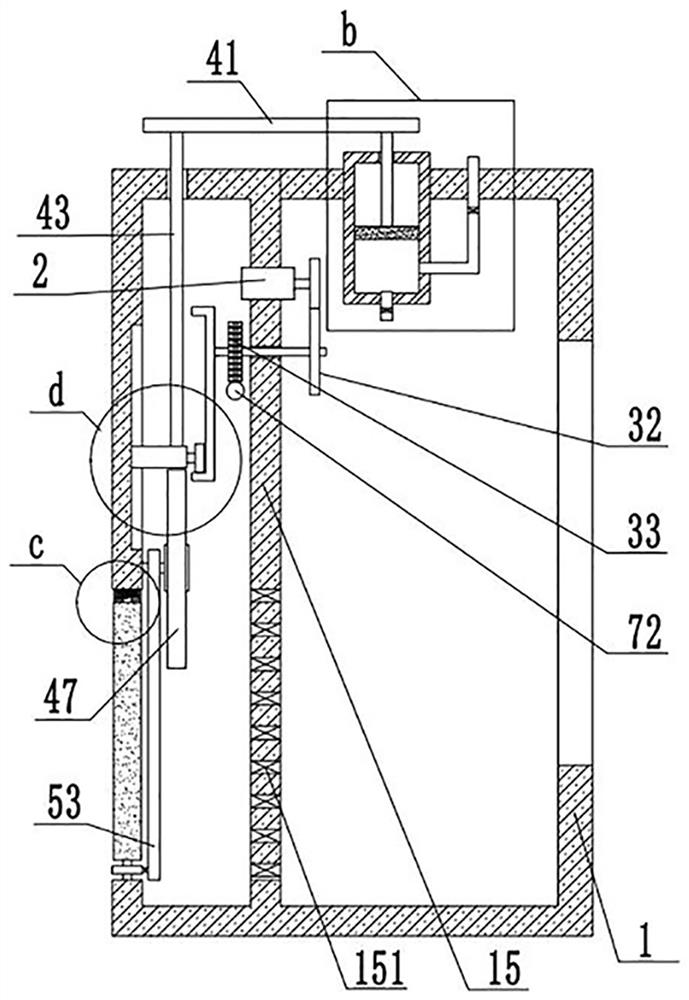

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

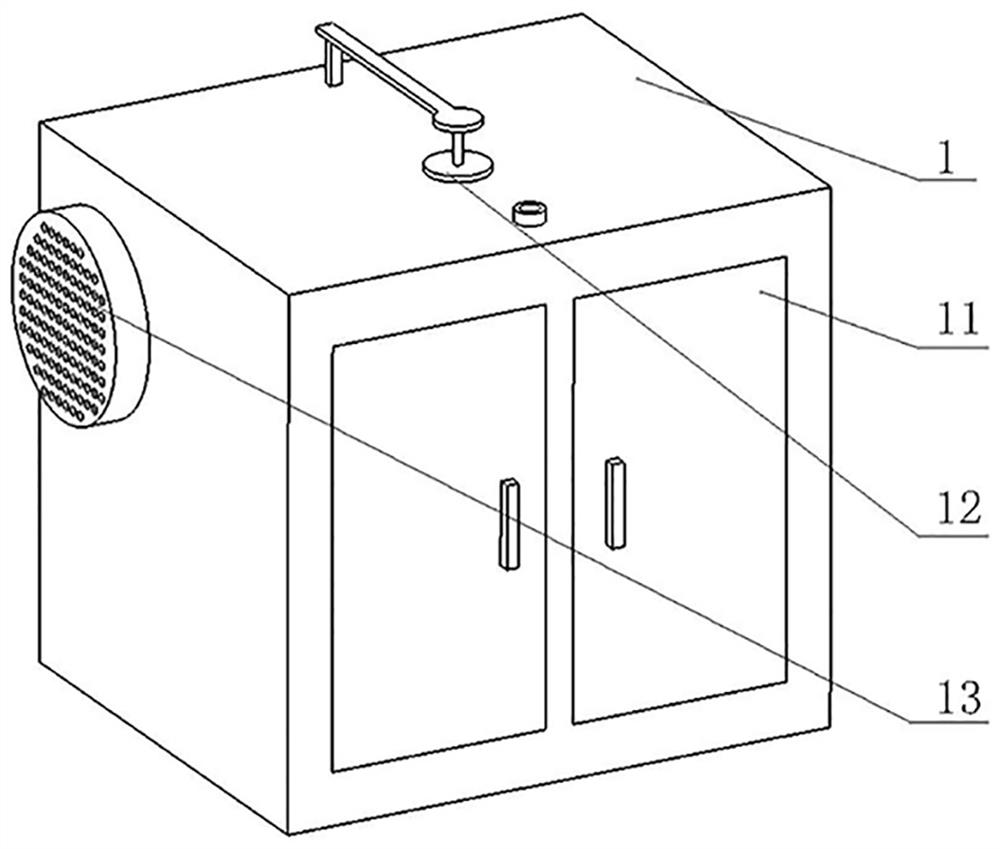

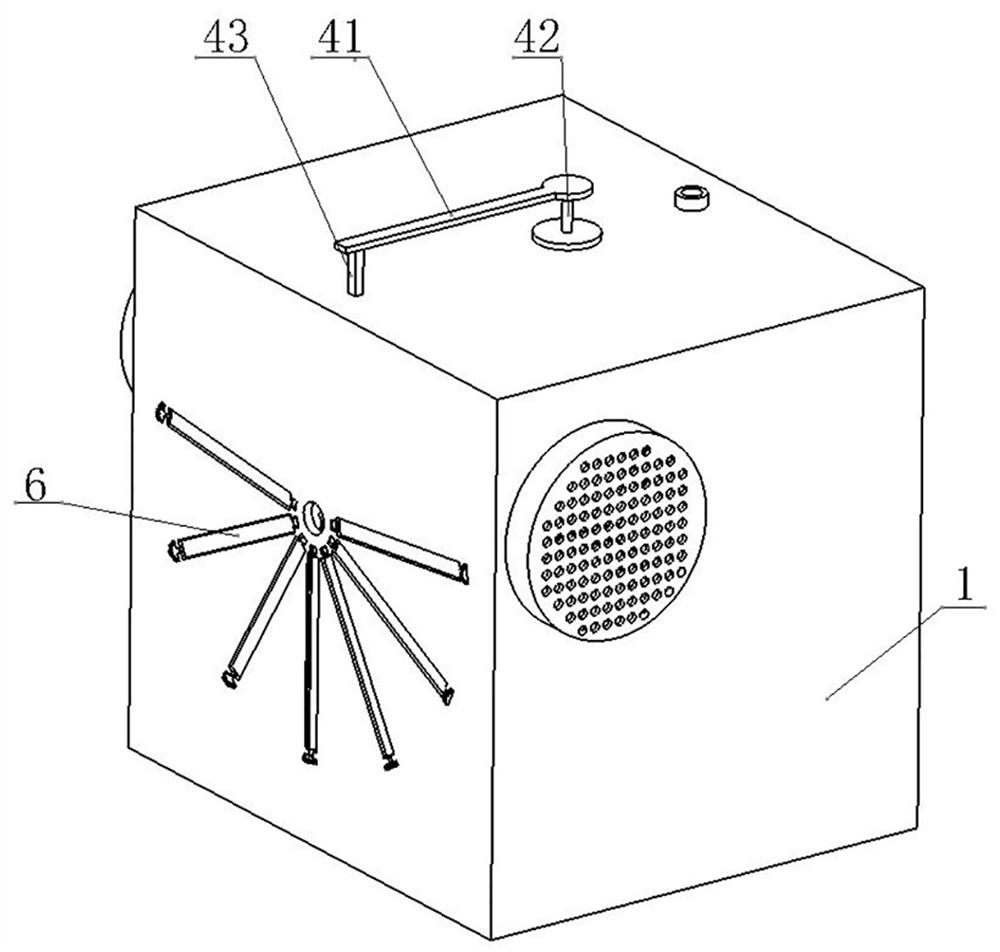

[0033] see Figure 1 to Figure 12 , the present embodiment provides a heat dissipation low-voltage switchgear, including a cabinet body 1, a plurality of mounting holes 14 are provided on the side wall of the cabinet body 1, a partition 15 is installed on the inner wall of the cabinet body 1, and the partition board 15 Ventilation holes 151 are provided on the top, and also include:

[0034] The driving part 2 installed on the partition 15, the driving part 2 includes a driving motor and a driving gear, and the driving motor is connected to the driving gear through a driving shaft;

[0035] The first transmission assembly 3 installed on the partition 15, the first transmission assembly 3 includes a first transmission gear 31 that is movably connected with the driving part 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com