Cable erecting device for electromechanical installation

A technology for installation and cables, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of time-consuming, laborious, troublesome, etc., and achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

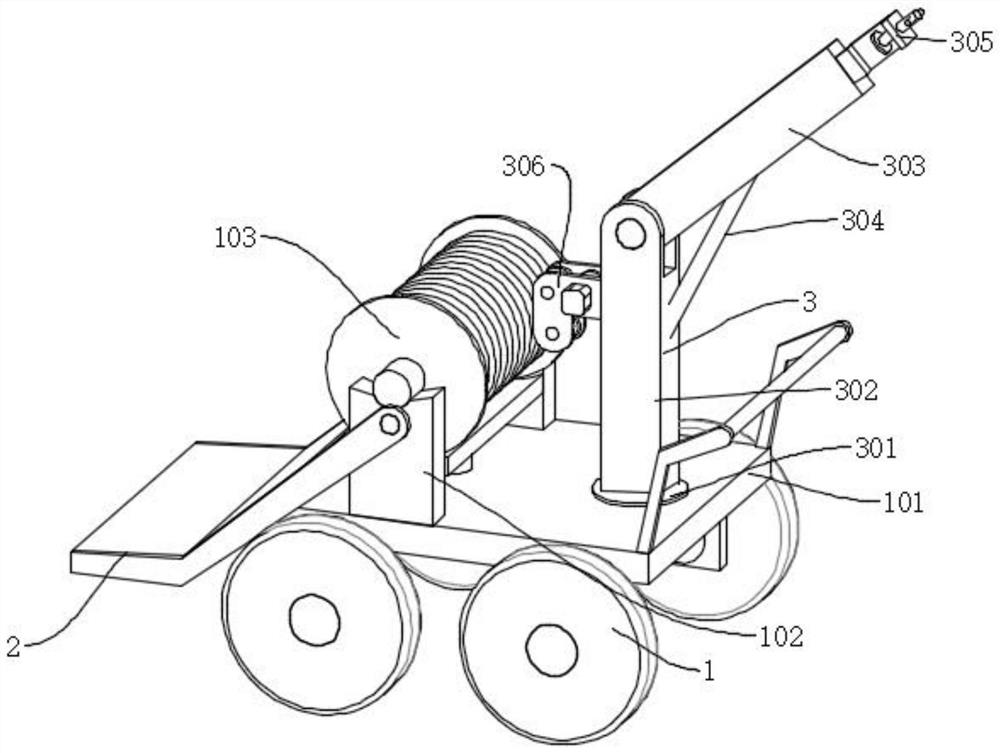

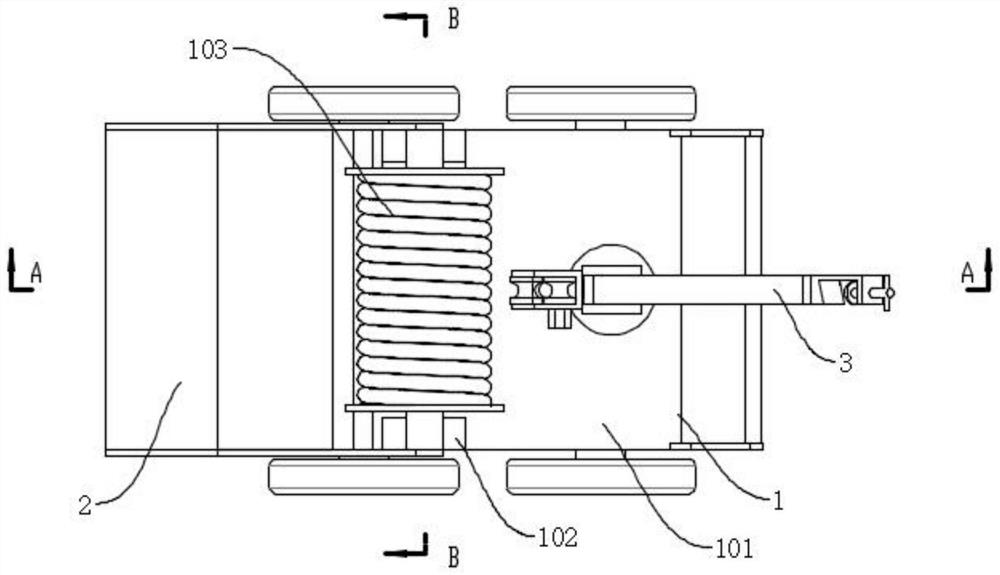

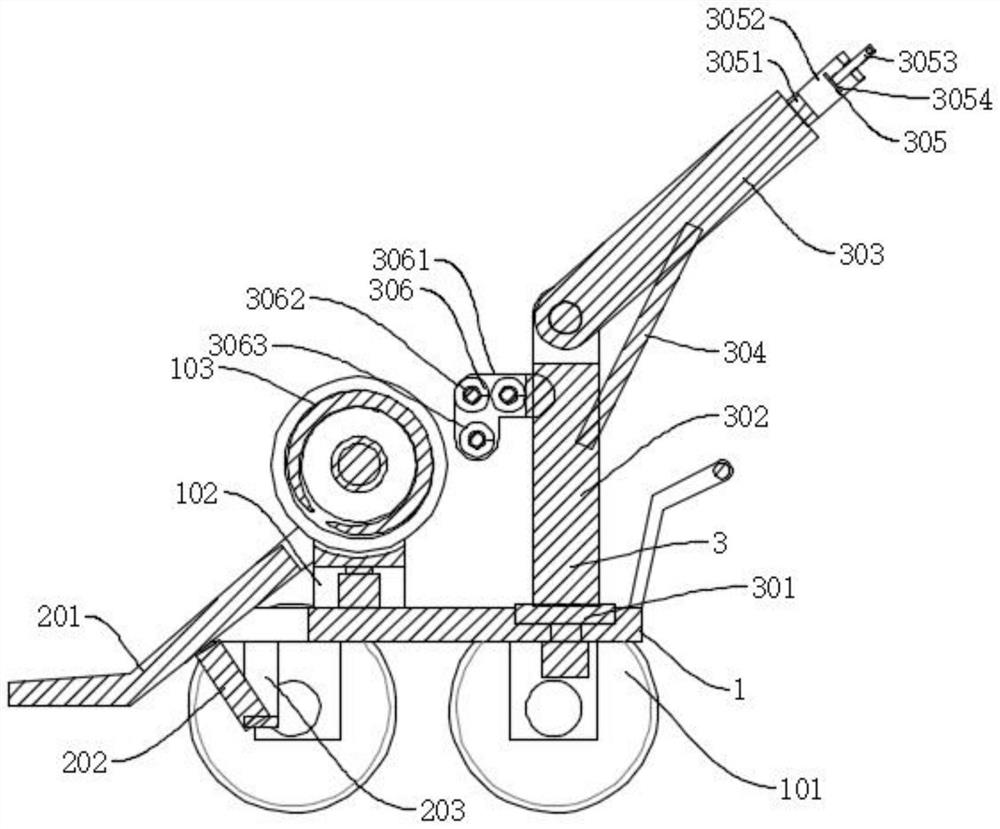

[0033] Such as Figure 1-Figure 8As shown, a cable erection device for electromechanical installation of the present invention includes a moving mechanism 1. The moving mechanism 1 is mainly composed of a moving trolley 101, a vertical plate 102, and a cable 103, and also includes an auxiliary feeding mechanism 2 and a lifting mechanism 3. The auxiliary feeding mechanism 2 includes a rotating plate 201, a first driving cylinder 202, and a mounting frame 203. One end of the rotating plate 201 is rotationally connected to the outside of the vertical plate 102, the other end of the rotating plate 201 is provided with a bending portion, and the bottom of the rotating plate 201 is rotationally connected At the output end of the first driving cylinder 202, the fixed end of the first driving cylinder 202 is connected to the inside of the mounting frame 203 in rotation, and the mounting frame 203 is connected to the bottom of the mobile trolley 101 by bolts. The pulling mechanism 3 inc...

Embodiment 2

[0036] Such as Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 is that an auxiliary unloading mechanism 4 is provided at the bottom of the cable 103, and the auxiliary unloading mechanism 4 includes a supporting plate 401 and a spring 41, and the supporting plate 401 is arranged at the bottom of the cable 103 The front and rear ends of the bottom of the supporting plate 401 are fixedly connected with springs 41, and the lower end of the spring 41 is connected to the top of the mobile trolley 101 by bolts. In this way, the spring 41 can drive the supporting plate 401 to rise, and the supporting plate 401 squeezes the cable 103, making it more labor-saving. The cable 103 is taken out from the inside of the arc-shaped groove to realize the function of assisting the removal of the cable 103 .

[0037] In the above structure, when the cable 103 is installed, the cable 103 is first moved to the top of the rotating plate 201, and then the rotating plate 201 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com