Cracking-free high-strength double-wall corrugated pipe

A double-wall corrugated pipe and corrugated pipe technology, applied in the field of corrugated pipes, can solve the problems of inconvenient placement of cables, scattered corrugated pipe bundles, long corrugated pipe lengths, etc., to improve stability, avoid surface cracking, and reduce cable installation. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

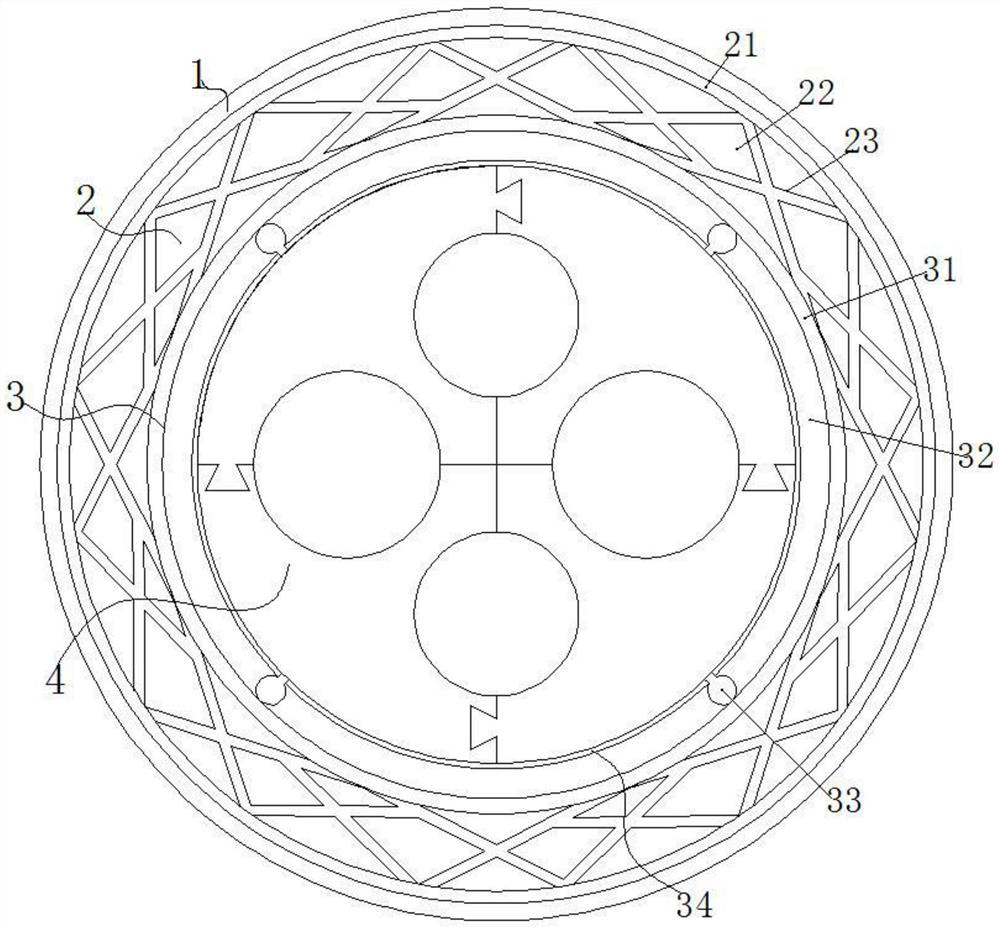

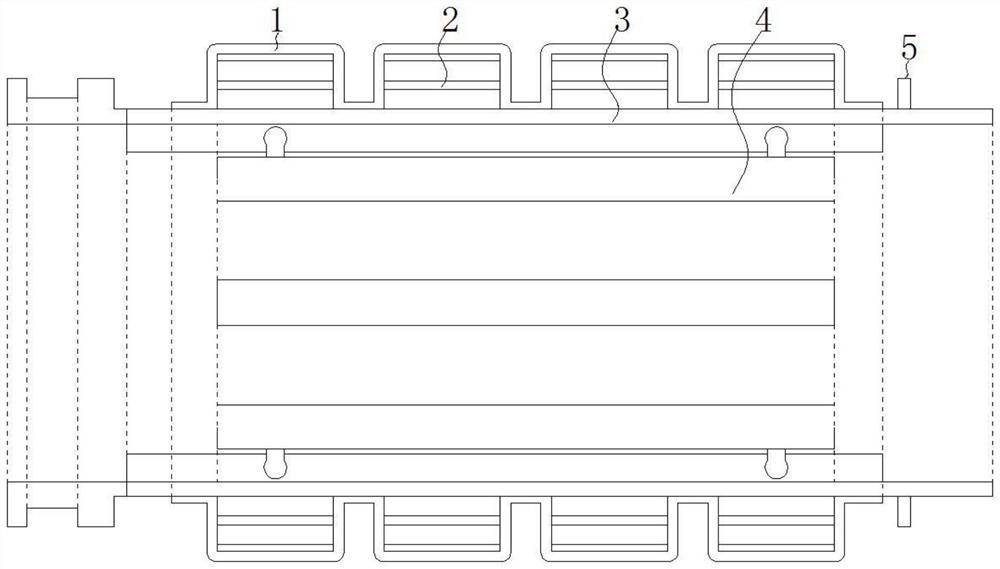

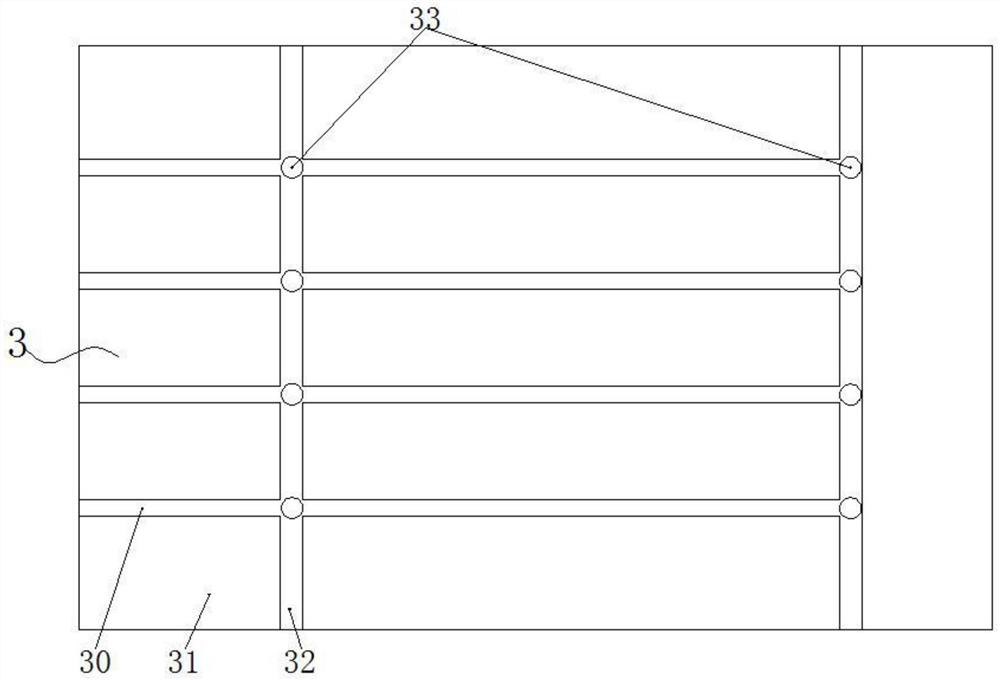

[0038] Specific implementation mode one: please refer to Figure 1-8 , the present invention provides a technical solution: a non-cracking high-strength double-wall corrugated pipe, comprising: a corrugated pipe body 3, a clamping structure 4 and a connecting structure 5;

[0039] The outer side of the bellows body 3 is evenly installed with multiple sets of outer reinforcing bushings 2, and the distance between two adjacent sets of outer reinforcing bushings 2 is the same, while the outer side of the outer reinforcing bushings 2 is wrapped with reinforced armor 1, and the bellows The inside of the body 3 is provided with a placement cavity 34, and the interior of the placement cavity 34 is provided with a clamping structure 4;

[0040]The clamping structure 4 is a detachable structure inside the bellows body 3, and the clamping structure 4 is composed of four parts: the first clamping block 41, the second clamping block 42, the third clamping block 43 and the fourth clamping ...

specific Embodiment approach 2

[0044] Embodiment 2: This embodiment is a further limitation of Embodiment 1. The cross-sections of reinforced armor 1, outer reinforced bushing 2 and bellows body 3 are concentric circle structures, and reinforced armor 1 and outer reinforced bushing 2 are combined in Together they constitute the outer reinforcement structure of the bellows body 3 .

[0045] Such as Figure 1-2 As shown: the reinforcement armor 1 and the outer reinforcement bushing 2 form the reinforcement structure of the bellows body 3, and the reinforcement armor 1 covers the outside of the bellows body 3, which can avoid direct irradiation of strong ultraviolet rays on the outer surface of the bellows body 3, Avoid surface cracking of the bellows body 3 .

specific Embodiment approach 3

[0046] Embodiment 3: This embodiment is a further limitation of Embodiment 2. The outer reinforcing bush 2 includes an outer casing 21, an inner cavity 22 and reinforcing ribs 23, and the outer casing 21 covers the outer side of the bellows body 3, while the inside of the outer casing 21 An inner cavity 22 is provided, and a plurality of sets of reinforcing ribs 23 are evenly and fixedly arranged in the inner cavity 22, and the reinforcing ribs 23 are arranged in an "X" shape.

[0047] Such as figure 1 and Figure 6 As shown: there are multiple groups of reinforcing ribs 23 evenly fixed inside the jacket 21. When the surface of the jacket 21 resists compression, the pressure acts on the surface of the reinforcing ribs 23, and the reinforcing ribs 23 resist this pressure, so that the corrugated pipe body 3 for anti-pressure protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com