Steel sheet for pressure vessel having excellent low-temperature lateral expansion, and method for manufacturing same

A pressure vessel and low temperature technology, which is applied in the field of steel plates for low temperature pressure vessels and its manufacture, can solve the problems of insufficient lateral low temperature expansion characteristics of steel, and achieve the effect of excellent lateral expansion characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0069] Hereinafter, the present disclosure will be described in more detail with reference to Examples.

[0070] (Example)

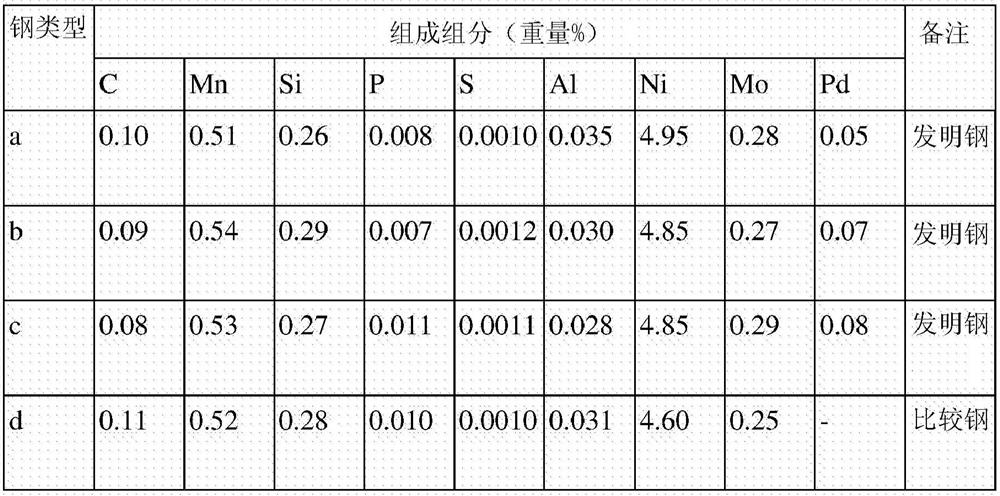

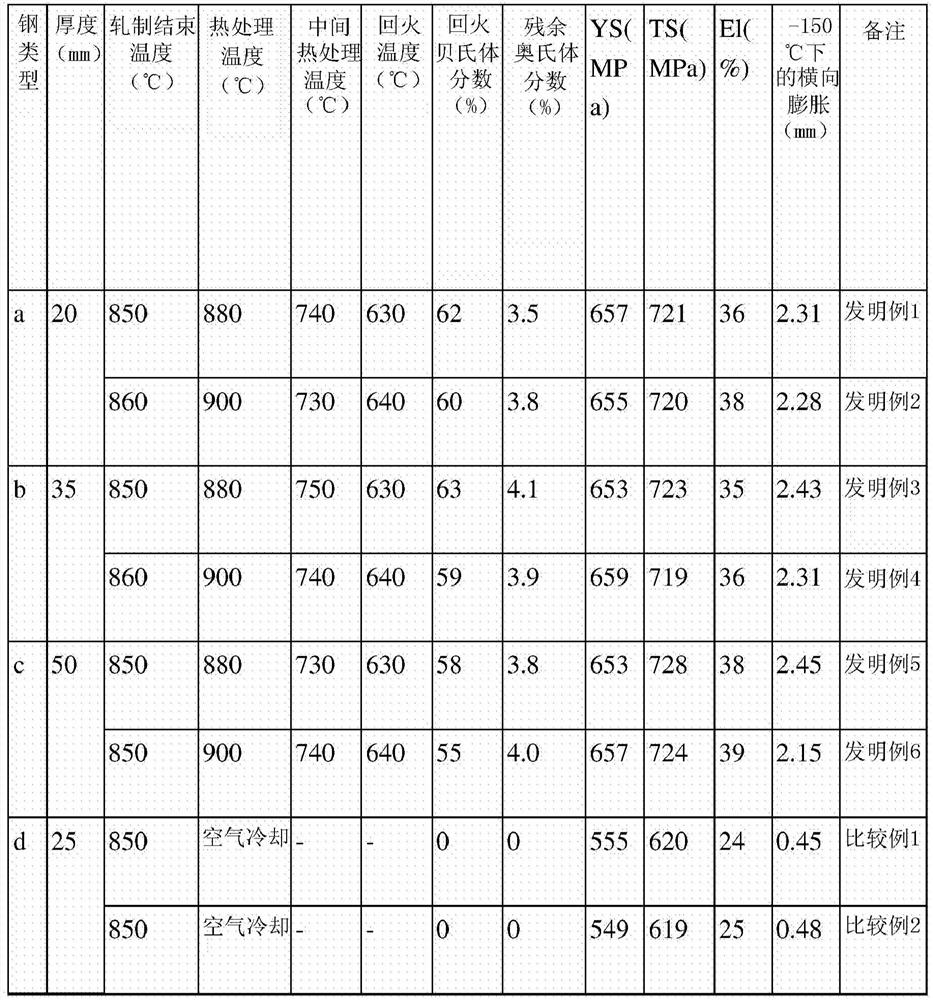

[0071] After preparing the respective steel slabs having the compositional components shown in Table 1 below, these steel slabs were reheated at a temperature ranging from 1050°C to 1250°C. The reheated steel sheets are respectively subjected to hot rolling at a reduction ratio of 5% to 30% per pass to manufacture hot-rolled steel sheets. Then, after the hot-rolled steel sheets thus manufactured were air-cooled, the air-cooled hot-rolled steel sheets were subjected to heat treatment, intermediate heat treatment, and tempering under the conditions shown in Table 2 to manufacture pressure vessel steel sheets. In this case, the heat treatment time, the intermediate heat treatment time and the tempering time were kept constant: 80 minutes for steel type a, 105 minutes for steel type b, and 140 minutes for steel type c.

[0072] The phase fractions of tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com