Preoperative appliance sterile equipment for surgical operation

A technology for surgical operations and chemical equipment, applied in the field of aseptic equipment for instruments, can solve the problems of difficult collection and disinfection methods, singleness, etc., and achieve the effect of avoiding incomplete disinfection and easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

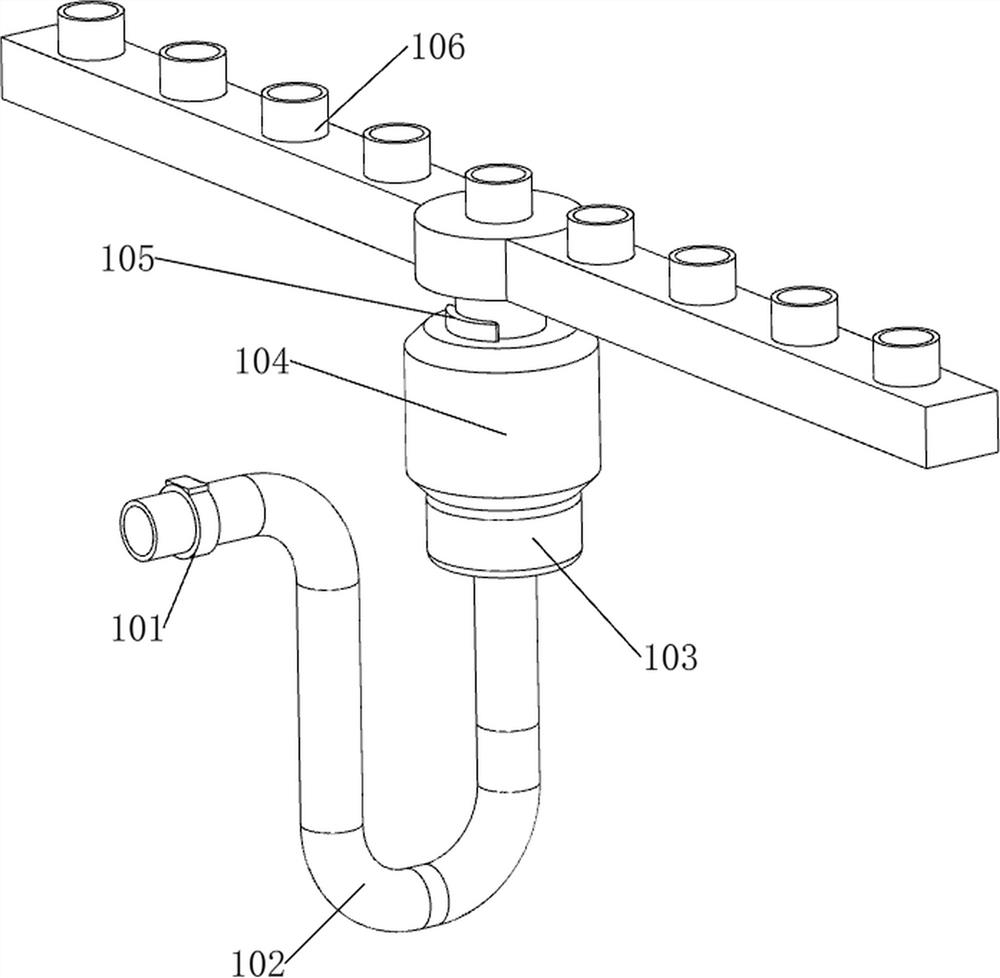

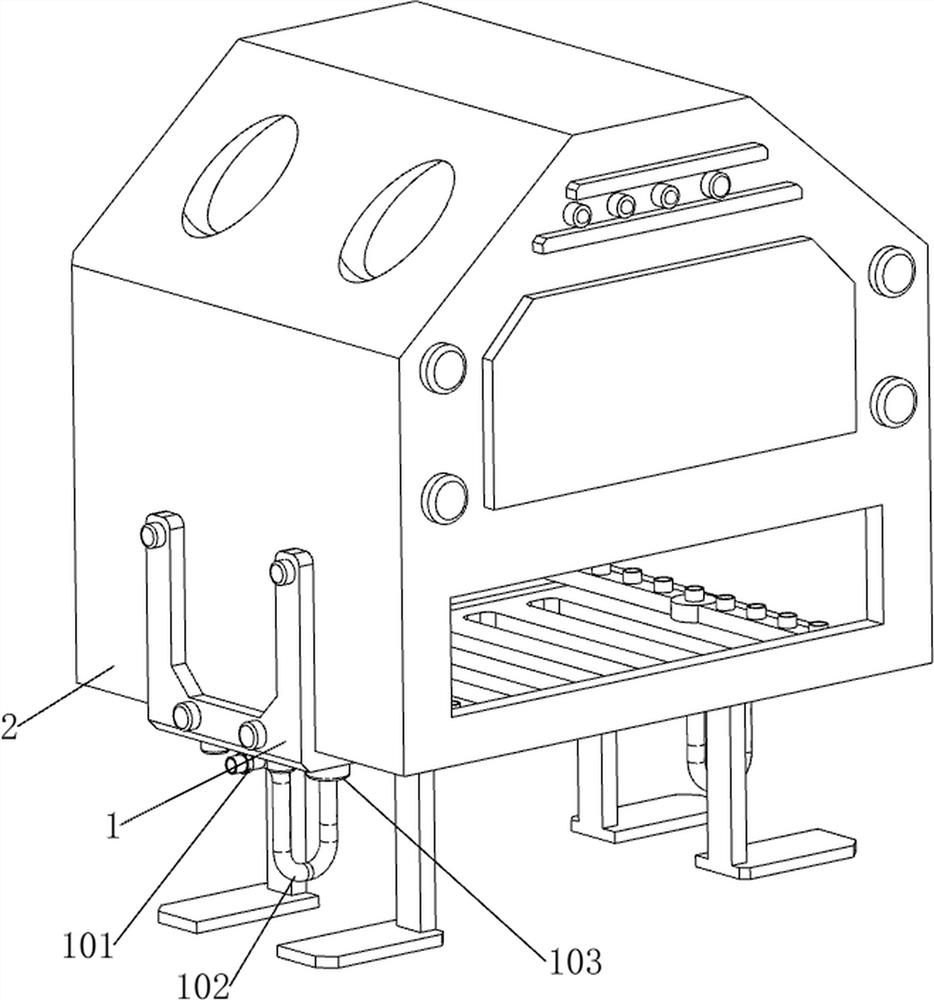

[0038] A kind of aseptic equipment for preoperative instruments for surgical operations, now refer to Figure 1-3 , including a bottom frame 1, a shell 2, a support plate 21, a contact switch 4, an ultraviolet lamp 5, a first slide bar 6, a first spring 7, a fixed frame 8, a pull frame 94, a filter screen 96, a pull mechanism 9, a steam The disinfection mechanism 10, the pushing mechanism 11 and the moving mechanism 12, the shell 2 is fixedly connected between the upper sides of the two bottom frames 1 by bolts, and the bottoms of the two bottom frames 1 are connected with two support plates 21 symmetrically front and back, and the front of the shell 2 A contact switch 4 is arranged on the right side of the upper side of the upper part, and a first slide bar 6 is provided on the left and right sides of the casing 2, and an ultraviolet lamp 5 is slidably connected between the two first slide bars 6, and the ultraviolet lamp 5 is used for The utensil is sterilized, the first spr...

Embodiment 2

[0045] On the basis of embodiment 1, now refer to Figure 14 , also includes a drainage mechanism 13, the drainage mechanism 13 includes a sewage pool 131, a liquid level sensor 132 and a solenoid valve 133, a sewage pool 131 is connected between the lower sides of the two chassis 1, and the sewage pool 131 is used to collect excess sewage A liquid level sensor 132 is provided on the front side of the sewage tank 131 , and a solenoid valve 133 is provided on the lower side of the rear part of the sewage tank 131 .

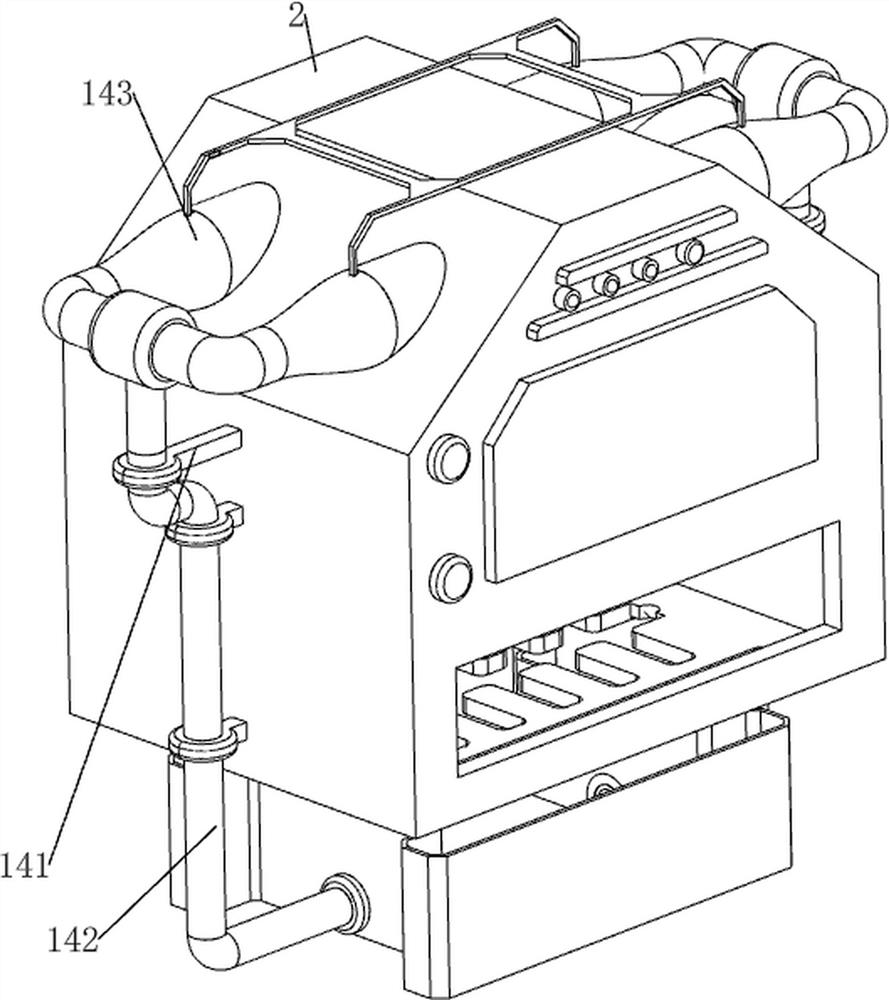

[0046] now refer to Figure 15-16 , also includes a steam export mechanism 14, the steam export mechanism 14 includes a third installation block 141, a pipe 142, a heat dissipation pipe 143, a second installation frame 144 and a fan group 145, and three third installations are arranged on the left and right sides of the casing 2. Block 141, pipes 142 are connected between the three third installation blocks 141 on the same side and the sewage pool 131, heat dissip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com