Road engineering dust filtering device

A dust filter device and road engineering technology, which is applied in the direction of combination device, transportation and packaging, and separation of dispersed particles, can solve the problems of complex equipment, waste, and large consumption, and achieve the effect of ensuring the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

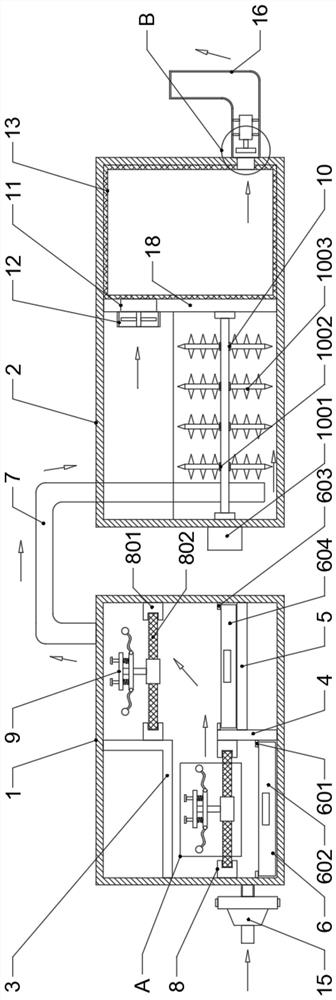

[0026] Example 1: Please refer to Figure 1-Figure 4 , a dust filter device for road engineering, comprising a primary filter box 1 and a secondary filter box 2, and also includes:

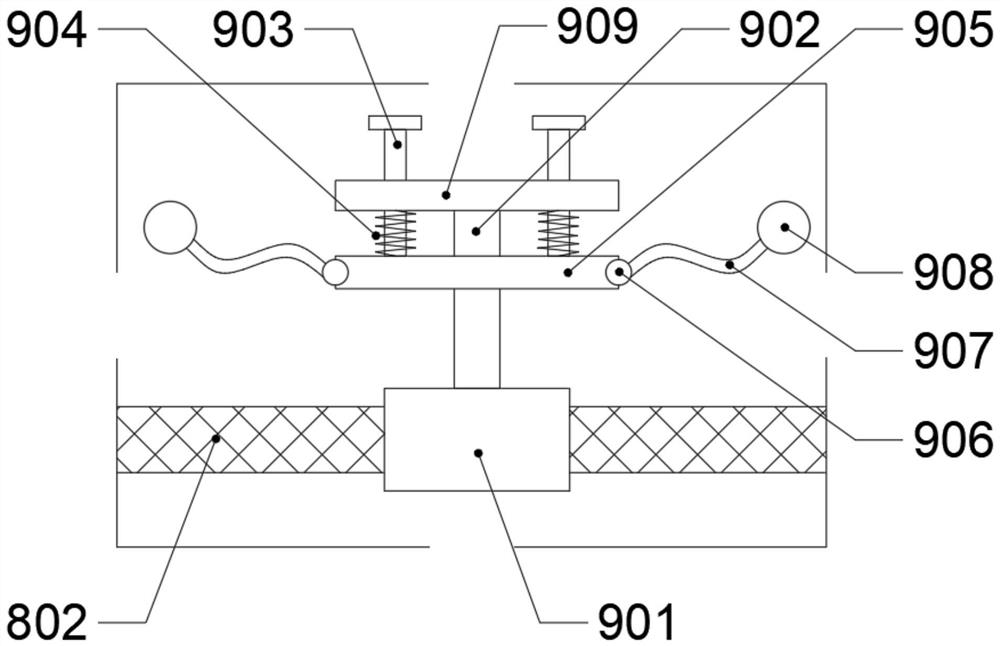

[0027] One side of the first-level filter box 1 is provided with an exhaust fan 15; the middle part of one end of the first-level filter box 1 is provided with a vertical plate 4, and the vertical plate 4 is connected to the inner wall of the first-level filter box 1 by a bracket 5. In the filter box 1, a channel plate 3 is arranged on the side opposite to the vertical plate 4, and the channel plate 3, the vertical plate 4 and the bracket 5 form an air circulation channel, and the channel plate 3 and the vertical plate 4 are connected with a filter mechanism 8, For primary filtering of the air, the filter mechanism 8 is connected with an anti-clogging mechanism 9 for cleaning the filter mechanism 8, and a storage mechanism 6 is also provided in the first-stage filter box 1 for storing the cleaned ...

Embodiment 2

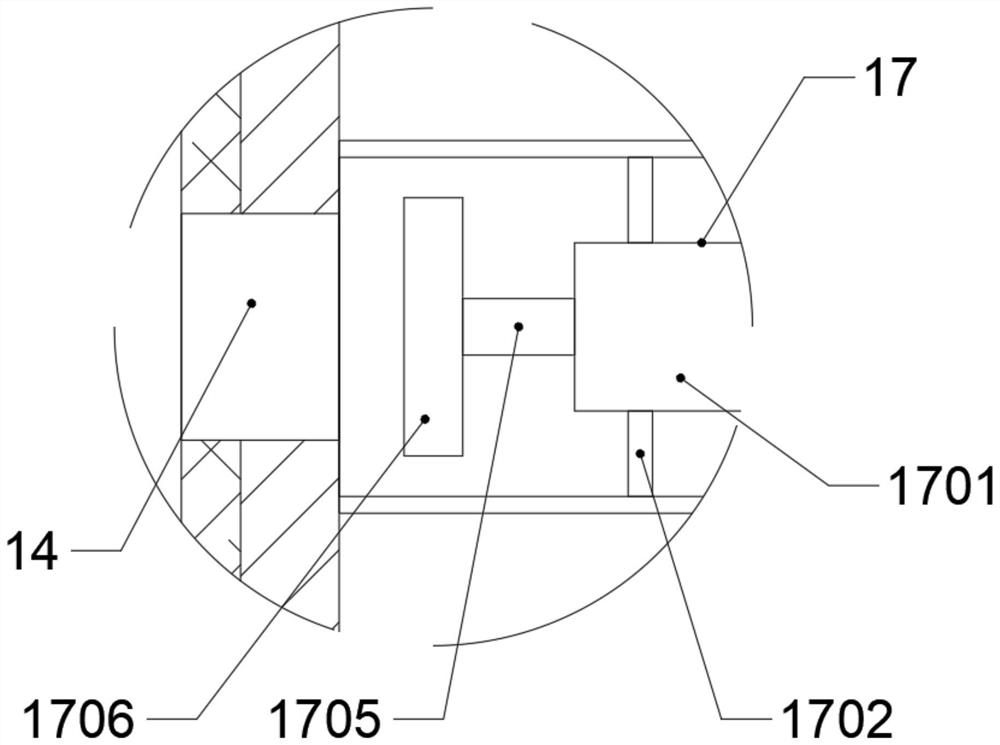

[0039] Embodiment 2: This embodiment is a further improvement on the previous embodiment: please refer to figure 1 , image 3 and Figure 4 In one case of this embodiment, the sealing mechanism 17 includes a fixing frame 1702 arranged in the exhaust pipe 16, a fixing cylinder 1701 is arranged on the fixing frame 1702, a second elastic member 1703 is arranged in the fixing cylinder 1701, and the second elastic member 1703 is arranged in the fixing cylinder 1701. The end of the second elastic member 1703 away from the fixed cylinder 1701 is connected with a movable plate 1704, and the movable plate 1704 slides in the fixed cylinder 1701. The movable plate 1704 is connected with a connecting rod 1705, and the end of the connecting rod 1705 far away from the movable plate 1704 is provided with a sealable exhaust valve. Seal plate 1706 for port 14.

[0040] Specifically, when the second elastic member 1703 is in a natural state, the sealing plate 1706 is close to the exhaust port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com