Method for reducing energy consumption and oxygen production amount of medical shelter by using carbon dioxide absorption machine

A carbon dioxide and absorption machine technology, applied in chemical instruments and methods, separation methods, transportation and packaging, etc., can solve the problems of reducing the number of air changes in the cabin, achieve the goals of reducing volume and weight, improving adaptability, and reducing working capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

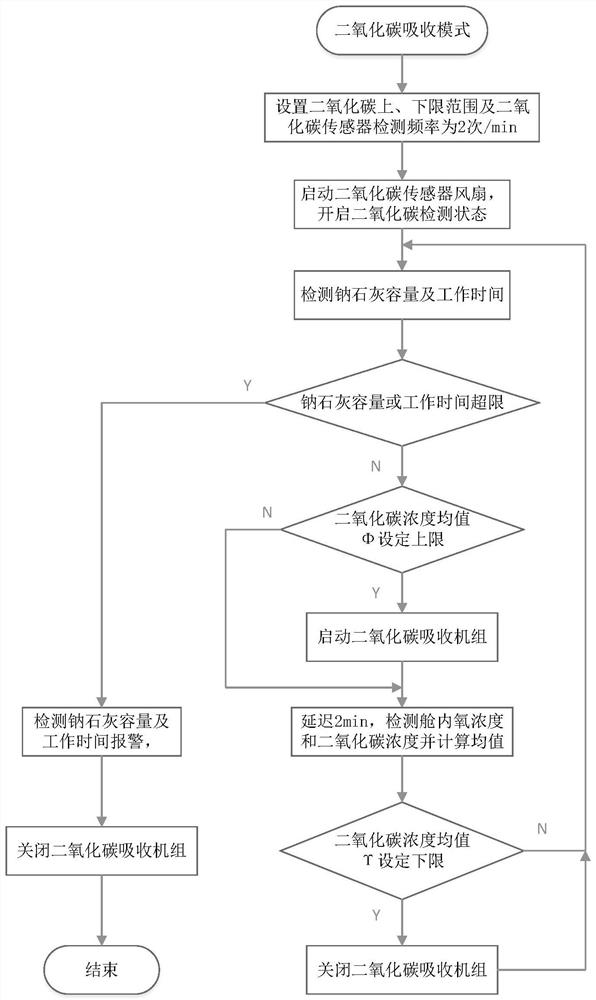

[0037] see Figure 1-3 According to a preferred embodiment of the present invention, a method for reducing energy consumption and oxygen production in a medical shelter by a carbon dioxide absorber is provided, which is characterized in that it includes:

[0038] Set up a carbon dioxide absorber;

[0039] The carbon dioxide sensor in the carbon dioxide absorber monitors the concentration of carbon dioxide in the cabin in real time, and determines whether to start the carbon dioxide absorber to absorb carbon dioxide according to the concentration of carbon dioxide.

[0040] Preferably, a temperature sensor is set to detect the ambient temperature outside the medical shelter, and when the ambient temperature detected by the temperature sensor is greater than the first predetermined temperature or lower than the second predetermined temperature, at least a part of the return air in the cabin is sent to the fresh air After the unit is processed, it is transported to the medical s...

Embodiment approach

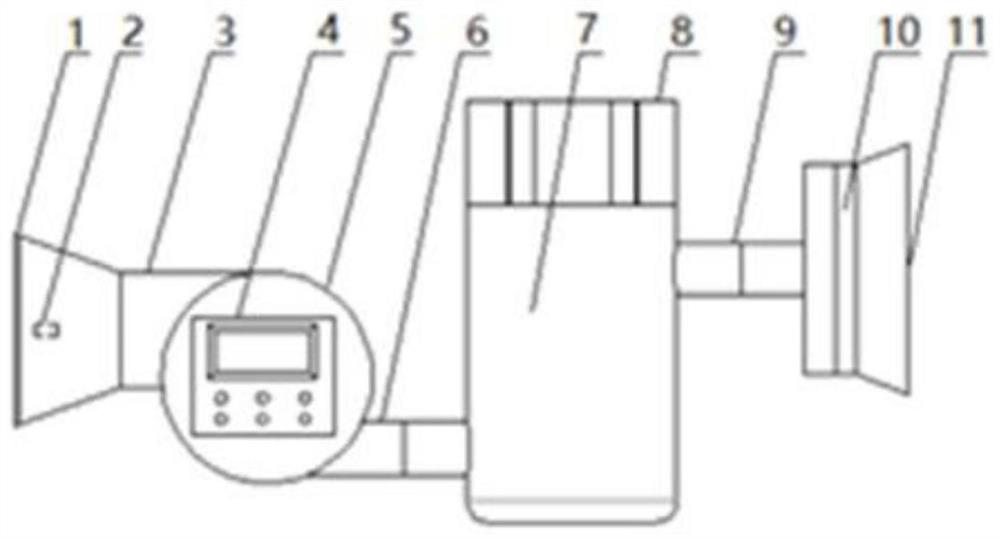

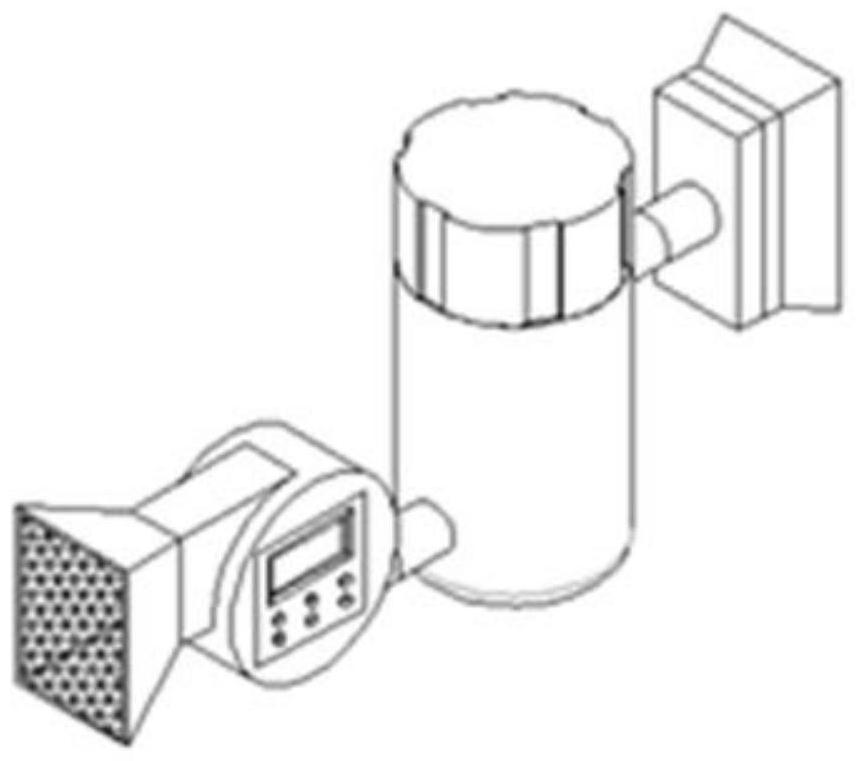

[0043] According to yet another preferred embodiment of the present invention, the linkage control system includes a control panel 4 .

[0044] According to yet another preferred embodiment of the present invention, the top of the soda lime absorption tank 7 is provided with a sealing cover 8 for the absorption tank.

[0045] According to another preferred embodiment of the present invention, the carbon dioxide sensor in the carbon dioxide absorber monitors the concentration of carbon dioxide in the cabin in real time, and determining whether to start the carbon dioxide absorber to absorb carbon dioxide according to the concentration of carbon dioxide includes:

[0046] When the carbon dioxide concentration exceeds 0.1%, start the carbon dioxide absorber, utilize the soda lime in the carbon dioxide absorber tank to combine with carbon dioxide, achieve the purpose of reducing the carbon dioxide concentration in the cabin; when the carbon dioxide concentration is lower than 0.5%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com