Impregnating tank

A technology for dipping tanks and tanks, which is applied in coatings, devices for coating liquid on the surface, etc., which can solve the problem that the pressure of the dipping tank cannot be kept stable, and achieve the effect of improving the sealing effect and improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

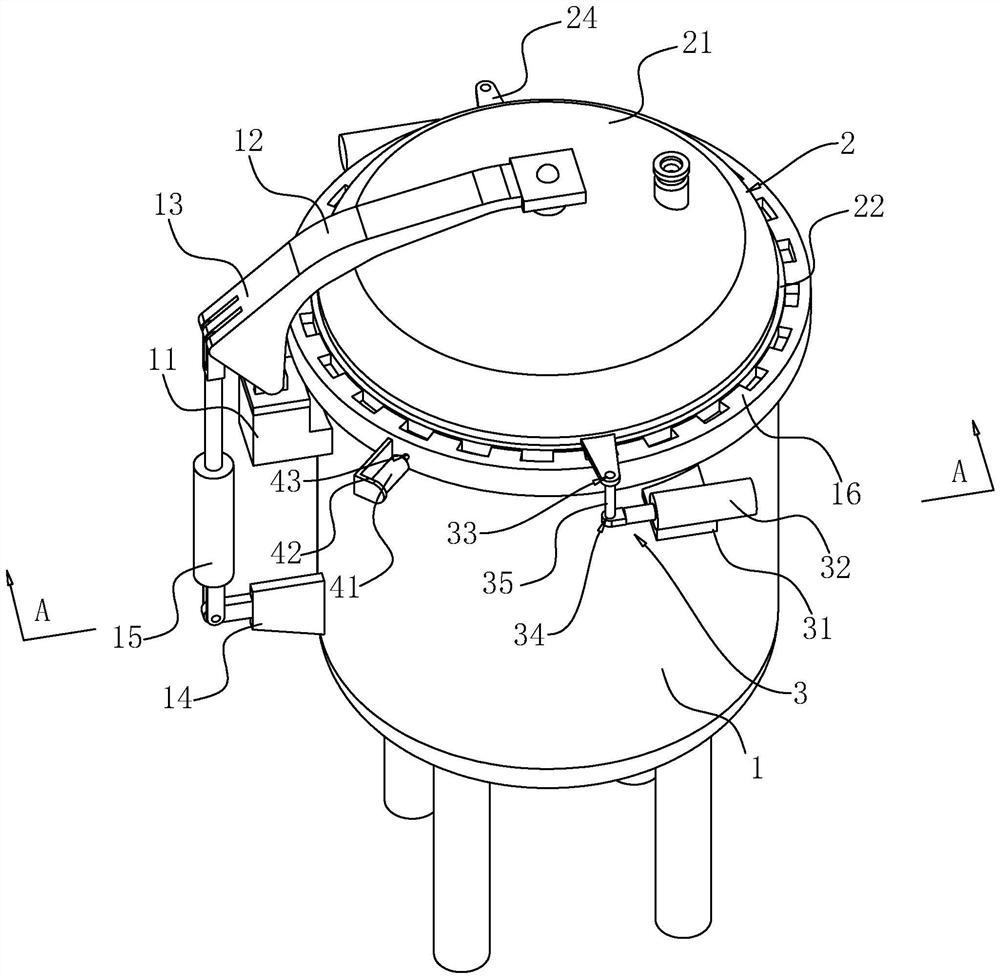

[0035] Embodiment 1 of the present application discloses a dipping tank. refer to figure 1 , a dipping tank includes a tank body 1 and a tank cover 2 hinged on the top of the tank body 1 . A connecting arm 11 is fixed on one side of the tank body 1 , and a connecting rod 12 is hinged to the top of the connecting arm 11 ; One side of the tank body 1 is fixed with a connection seat 14, and the connection seat 14 is hinged with a cylinder one 15 away from the tank body 1 side, and the hydraulic rod top of the cylinder one 15 is hinged with the hinge part 13 away from the connection rod 12 side.

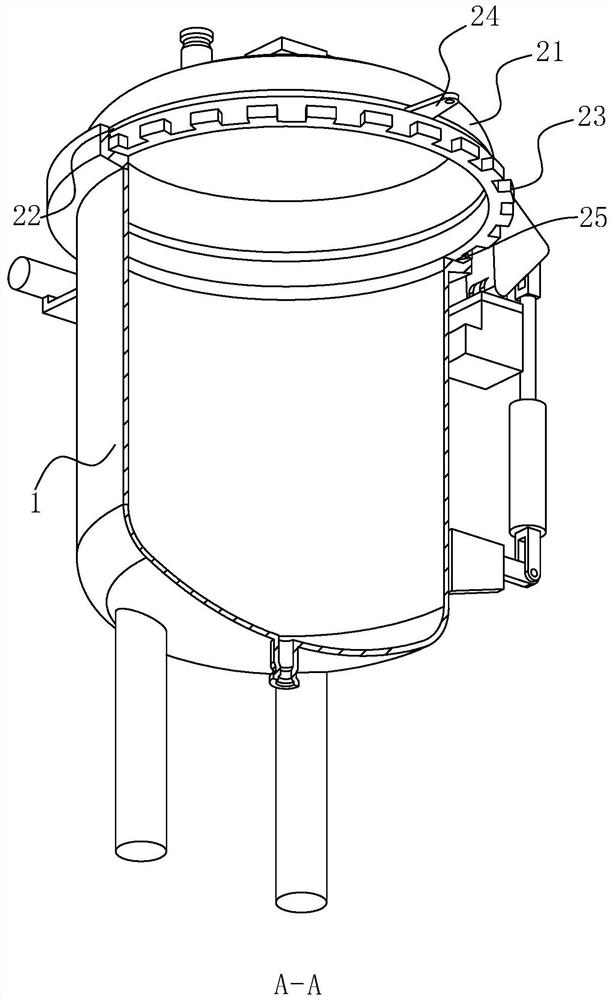

[0036] refer to figure 1 and figure 2 The tank cover 2 includes a cover top 21 rotatably connected to the bottom of the connecting rod 12 away from the end of the connecting arm 11 and a cover edge 22 integrally formed on the bottom of the cover top 21 . The cover has a plurality of meshing teeth-23 evenly distributed along the outer peripheral surface of the cover 22 along its circ...

Embodiment 2

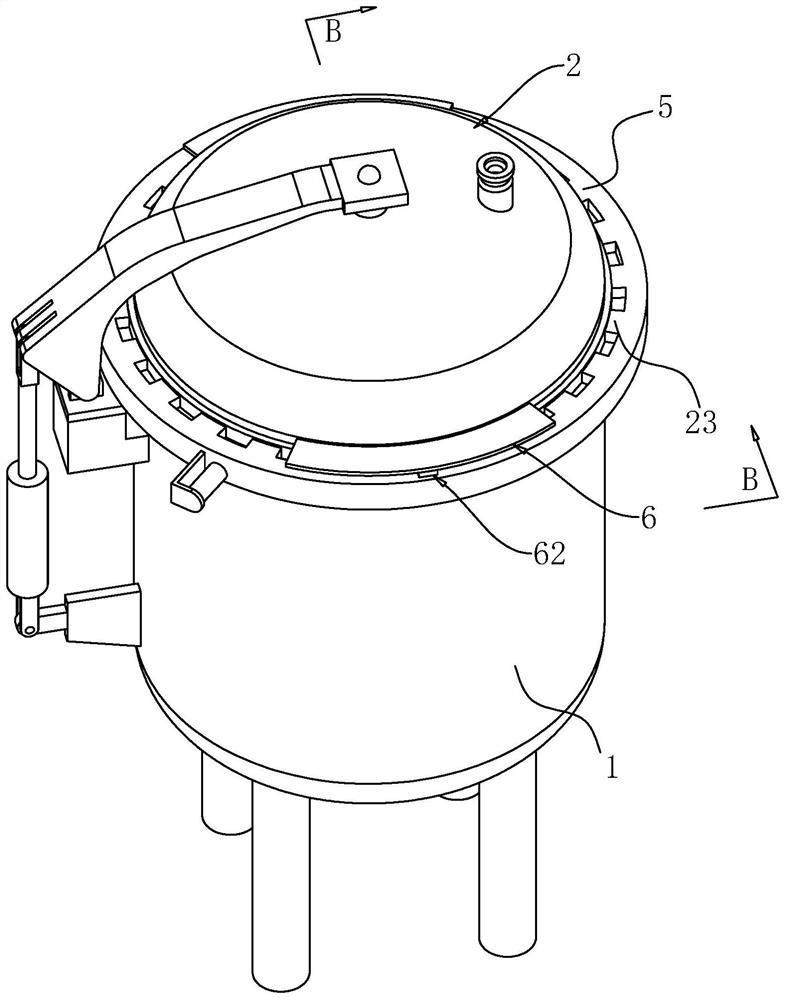

[0044] refer to image 3 and Figure 4 , The difference between Embodiment 2 and Embodiment 1 is that the rotating mechanism 3 includes a swivel 5 that is rotatably installed in the tank body 1 . The inner peripheral surface of the swivel 5 is evenly distributed along its circumferential direction with several third engaging teeth 51 for engaging with the first engaging teeth 23 .

[0045] refer to Figure 4 and Figure 5 , There are two limit boxes 52 relatively fixed on the inner peripheral surface of the tank body 1, and the cross section of the limit boxes 52 is arc-shaped. The inner wall of the limit box 52 is fixed with an electromagnet 53; the outer peripheral surface of the swivel 5 is fixed with a magnetic sheet 54 for magnetic adsorption with the electromagnet 53; Ring 5 rotates. The side of the electromagnet 53 close to the magnetic attraction piece 54 is fixed with a return spring 55 , and the end of the return spring 55 away from the electromagnet 53 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com