Buried type heat preservation and insulation roof steam exhaust system and construction method thereof

A thermal insulation and construction method technology, applied in the direction of ventilation system, roof covering, roof insulation materials, etc., can solve the problems of waterproof layer deformation, water vapor retention, thermal insulation layer or waterproof layer cracking, etc., to ensure waterproof, Prevent structural bulging and avoid stagnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solutions and beneficial effects of the present invention clearer, the preferred embodiments of the present invention will be described in detail below, so as to facilitate the understanding of the skilled person.

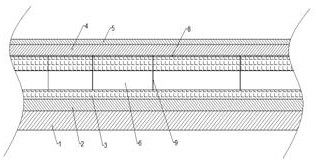

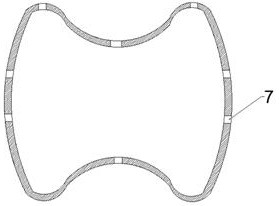

[0027] The concealed heat insulation roof steam exhaust system of the present invention comprises a roof base layer 1, a waterproof layer 2, a thermal insulation layer 3, a bonding net 8, a cement mortar thermal insulation layer 4, a flexible waterproof layer 5, and a steam exhaust pipe. criss-cross exhaust pipe network 6, vertical exhaust standpipes buried around the roof. Among them, the waterproof layer 2, the thermal insulation layer 3, the bonded mesh 8, the cement mortar thermal insulation layer 4, and the flexible waterproof layer 5 are sequentially arranged on the roof base layer 1 from bottom to top; the exhaust pipe network 6 is laid in the thermal insulation layer 3, Above the waterproof layer 2, a gap is re...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap