Washing machine with dust sensor and control method

A technology of dust sensor and control method, which is applied to the control device of washing machine, other washing machines, washing devices, etc., can solve the problems of clothes that cannot meet different degrees of dirtiness, clothes not properly washed, and waste of resources, etc., and achieves quick and convenient adjustment. , increase the degree of intelligence, and avoid the effect of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

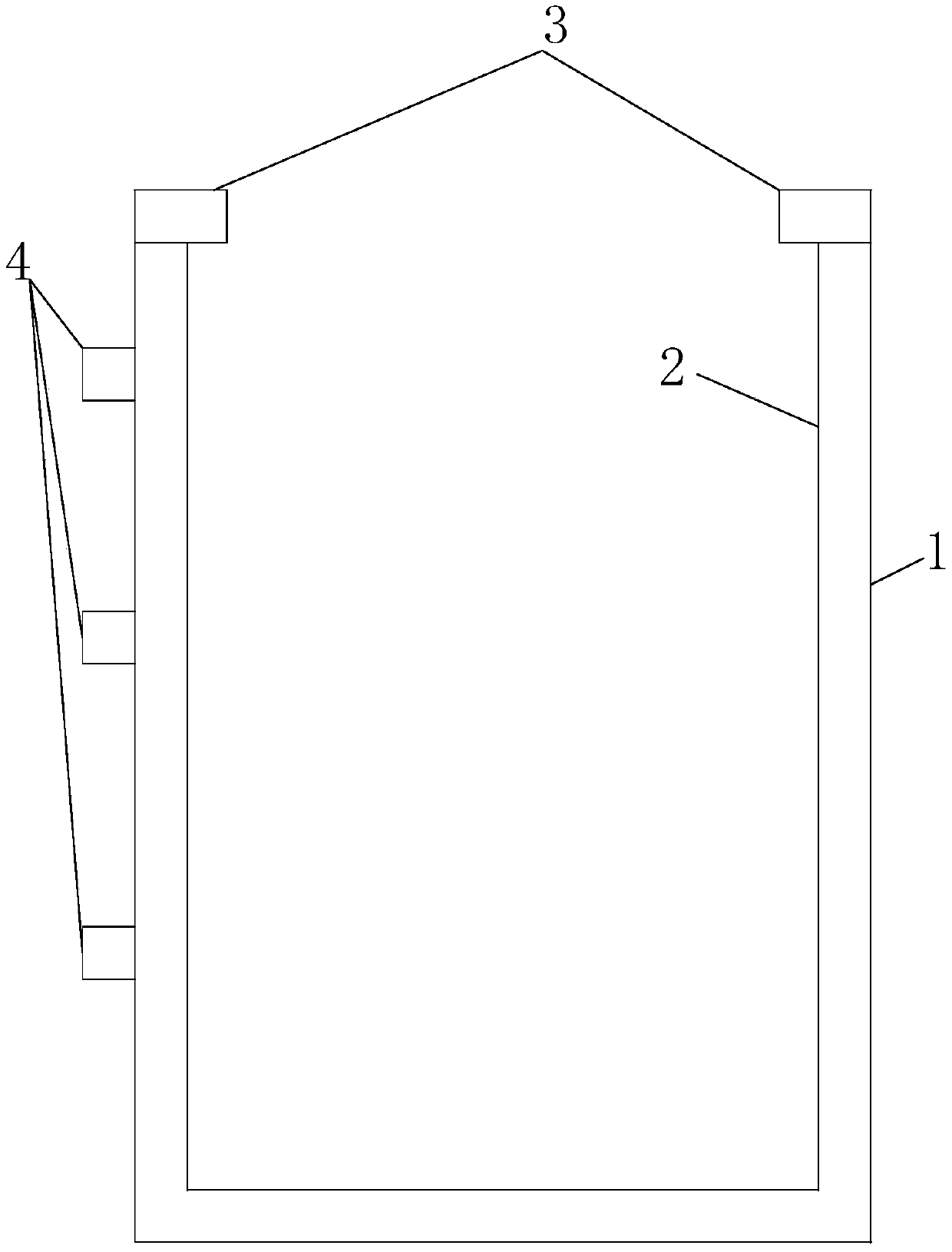

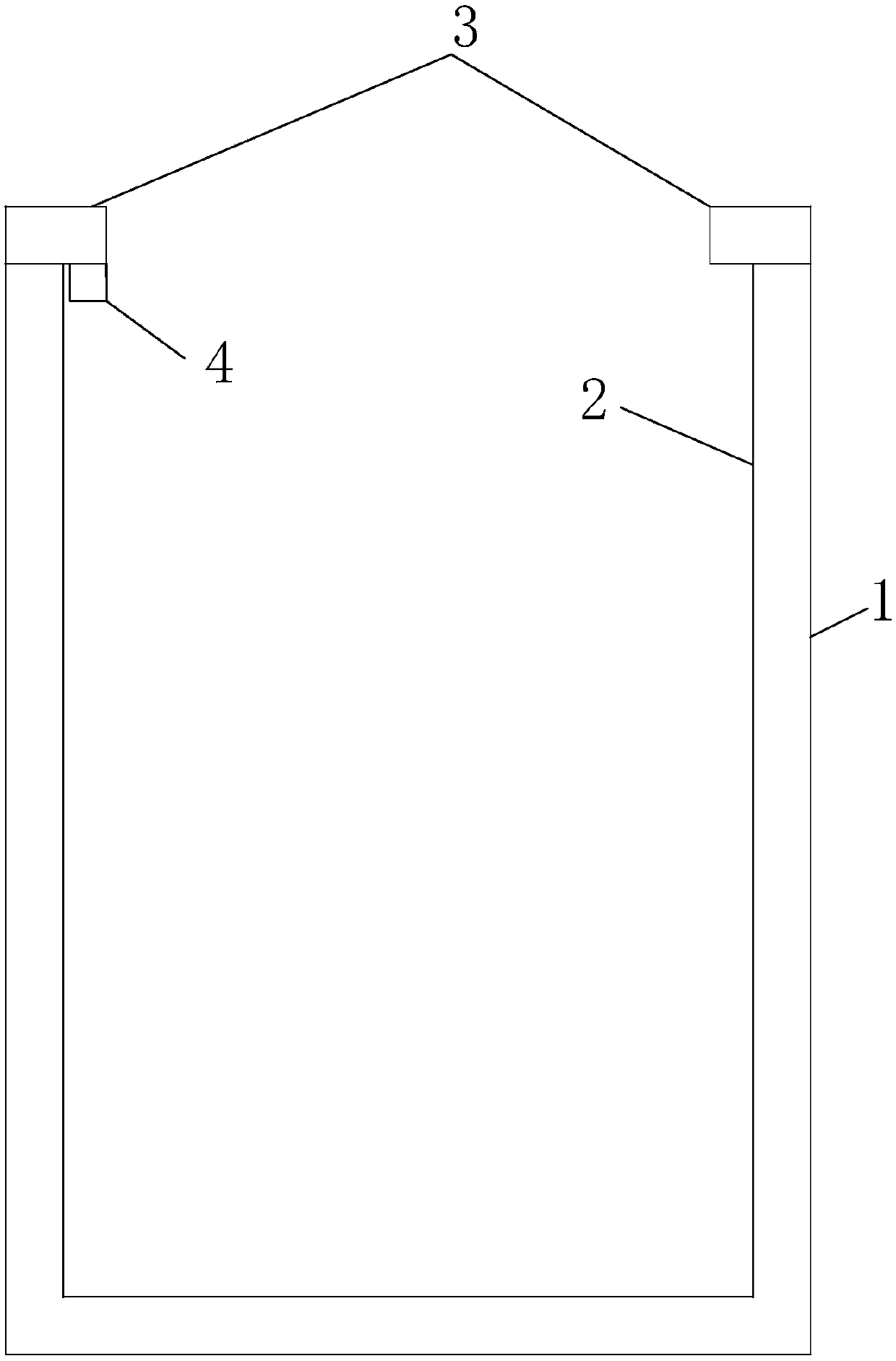

[0041] figure 1 , figure 2 It is a schematic diagram of the installation structure of the dust sensor in the washing machine according to the embodiment of the present invention. Wherein, the washing machine in the embodiment of the present invention may be a pulsator washing machine, which includes a motor and a pulsator. The pulsator rotates under the drive of the motor, and then drives the dry clothes in the inner tub to rotate. The washing machine includes an outer tub 1 , an inner tub 2 , a balancing ring 3 and a dust sensor 4 . In this embodiment, the detection of the dust content in the barrel refers to the area inside the inner barrel 2 of the washing machine or between the inner and outer barrels of the washing machine. The dust content in the inner tub 2 of the washing machine is detected by setting a dust sensor.

[0042] like figure 1 As shown, it is a schematic diagram of the installation structure of the dust sensor in the washing machine in an embodiment o...

Embodiment 2

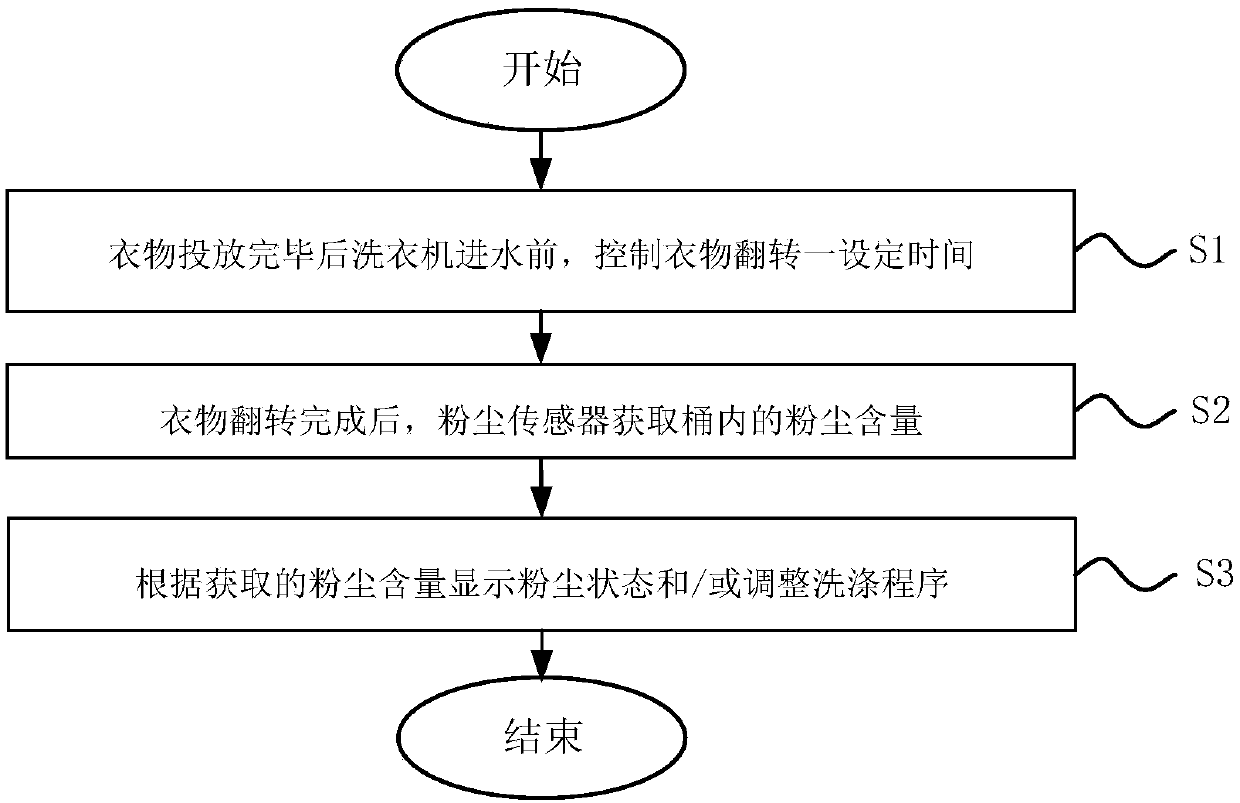

[0049] image 3 It is a flowchart of a washing machine control method according to an embodiment of the present invention. Wherein, the washing machine in the embodiment of the present invention may be a pulsator washing machine, which includes a motor and a pulsator. After the clothes are put in and before the washing machine enters the water, the pulsator rotates under the drive of the motor, and then drives the clothes in the inner bucket to turn over.

[0050] like image 3 As shown, the control method of the washing machine includes the following steps:

[0051] S1. After the clothes are put in, before the washing machine enters the water, the clothes are turned over for a set time.

[0052] After the clothes are put into the inner bucket of the washing machine, the user closes the upper cover of the washing machine and starts the washing process. At this time, the washing machine first starts the motor to rotate without adding water and any detergent. The motor rotat...

Embodiment 3

[0066] Figure 4 It is a flow chart of the control method of the washing machine in a specific embodiment of the present invention, such as Figure 4 As shown, the control method of the washing machine includes the following steps:

[0067] S101. After the laundry is put in, before the washing machine enters the water, control the laundry to turn over for a set time.

[0068] In this embodiment, in order to more fully shake the clothes put into the inner tub of the washing machine, dust, dander, hair and other particles and particles attached to the clothes can be fully diffused in the inner tub of the washing machine. The motor adopts a certain proportion of positive and negative rotation to drive the pulsator of the washing machine to stir the dry clothes, because the water will make the dust on the clothes easier to adhere to the clothes, so a relatively dry environment is required to have a good drying effect during the shaking process. It is conducive to the diffusion o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap