Simple plugboard device

A plug-in device and plug-in technology, which are applied to valve devices, sliding valves, valve details, etc., can solve the problems of inability to close, stuck, poor stability, etc., and achieve the effect of less production and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

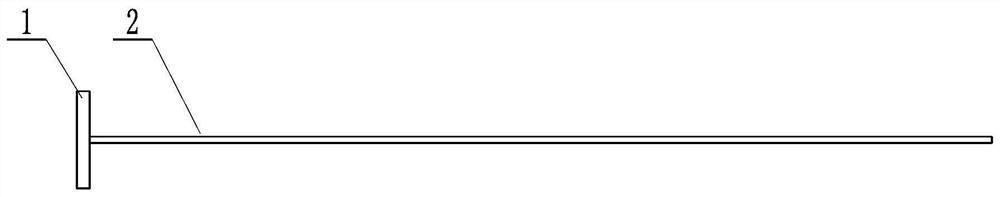

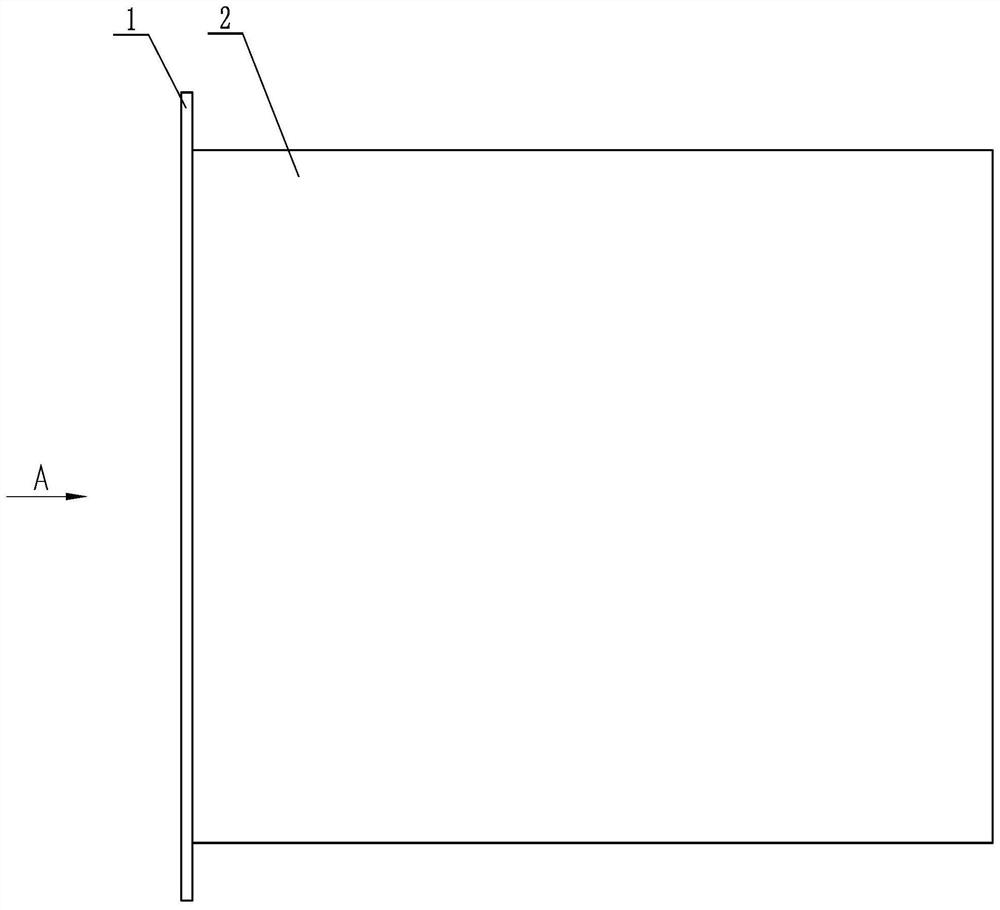

[0020] like figure 1 and figure 2 As shown, a simple inserting plate device of the present invention includes a inserting plate with a T-shaped cross section, and the inserting plate is welded by a flange blind plate 1 and a rectangular steel plate 2;

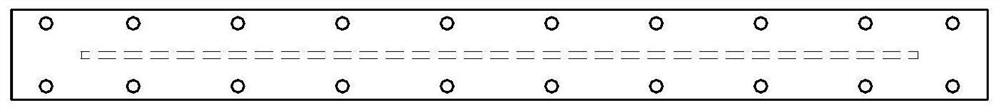

[0021] It also includes a T-shaped slot adapted to the T-shaped plug-in plate; the T-shaped slot is composed of an open slot body 3 adapted to a rectangular steel plate and a flange plate 4 arranged at the opening of the open slot body The two side panels of the open tank body are provided with through holes 5 matching the diameter of the pipeline; the flange plate on the T-shaped slot is set correspondingly to the flange blind plate on the T-shaped plug-in plate;

[0022] The T-shaped plug-in board is detachably installed in the T-shaped slot.

[0023] like Figure 8 As shown, in order to facilitate production and processing, the T-shaped slot is composed of three parts: it includes Figure 8 The flange assembly on the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com