Method for precisely measuring diameter of large-radius small-arc molded surface by using formula method

A large-radius, arc-shaped technology, applied in the field of arc diameter measurement, to achieve the effect of improving measurement efficiency, avoiding error amplification, and widely promoting significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

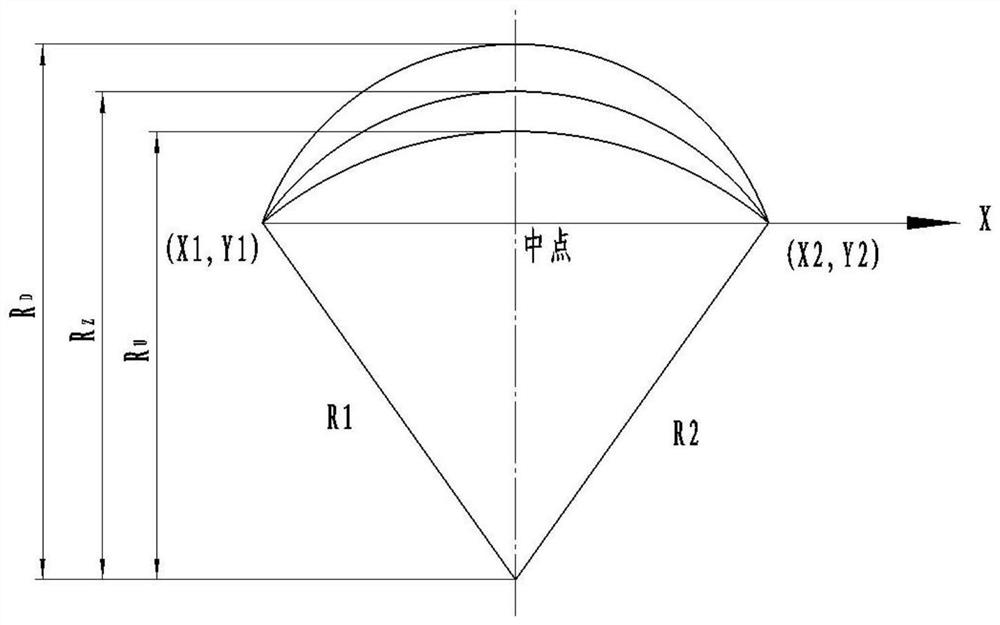

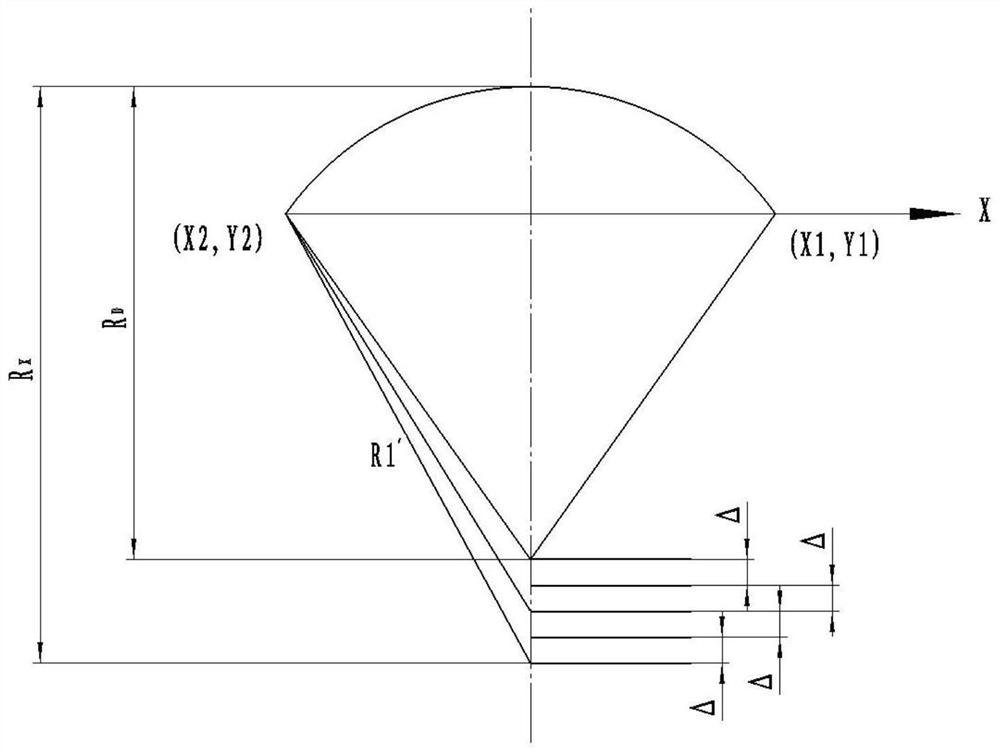

[0032] see figure 1 and figure 2 , in this embodiment, the measurement method is specifically:

[0033] Ⅰ. Establish a coordinate system based on the projection surface of the arc, the two ends of the arc (point 1 and point 2) and the midpoint of the arc;

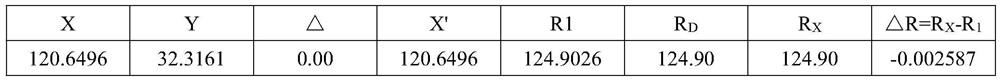

[0034] Ⅱ. After the coordinate system is established, set the method of collecting points so that the probe touches the surface along the direction of the theoretical vector to obtain point 1 and point 2. Fine-tune the origin position of the coordinate system in the X direction and record the coordinate position (X 1 , Y 1 ), (X 2 , Y 2 ), make|X 1 |=|X 2 |, |Y 1 |=|Y 2 |;

[0035]In this embodiment, point 1, point 2 and their midpoint are used to construct the original coordinate system, and the theoretical lower difference radius is the new zero point through the circular arc vertex offset theory, and the coordinates of point 1 (X 1 , Y 1 ) and point 2 coordinates (X 2 , Y 2 ), we know that |X 1 |=|X 2 |, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com