Label taking mechanism for chip heat dissipation stickers

A chip heat dissipation and header technology, which is applied to the field of the labeling mechanism of chip heat dissipation stickers, can solve problems such as poor generality of headers, and achieve the effects of solving air bubbles, facilitating discharge, and improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

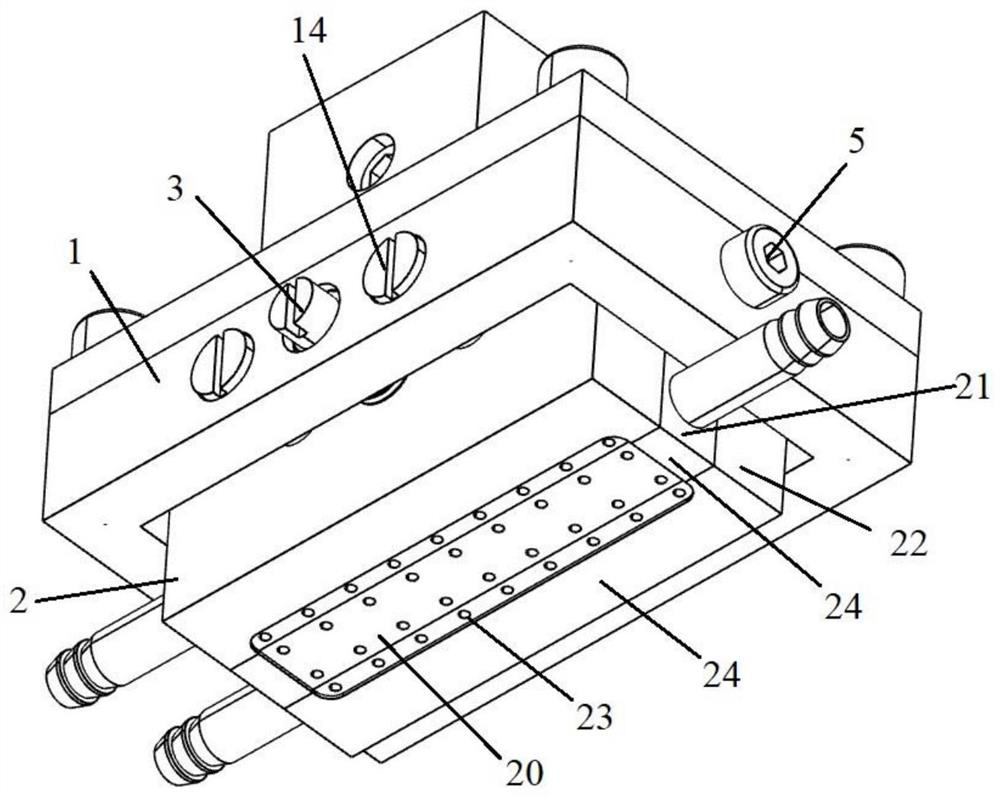

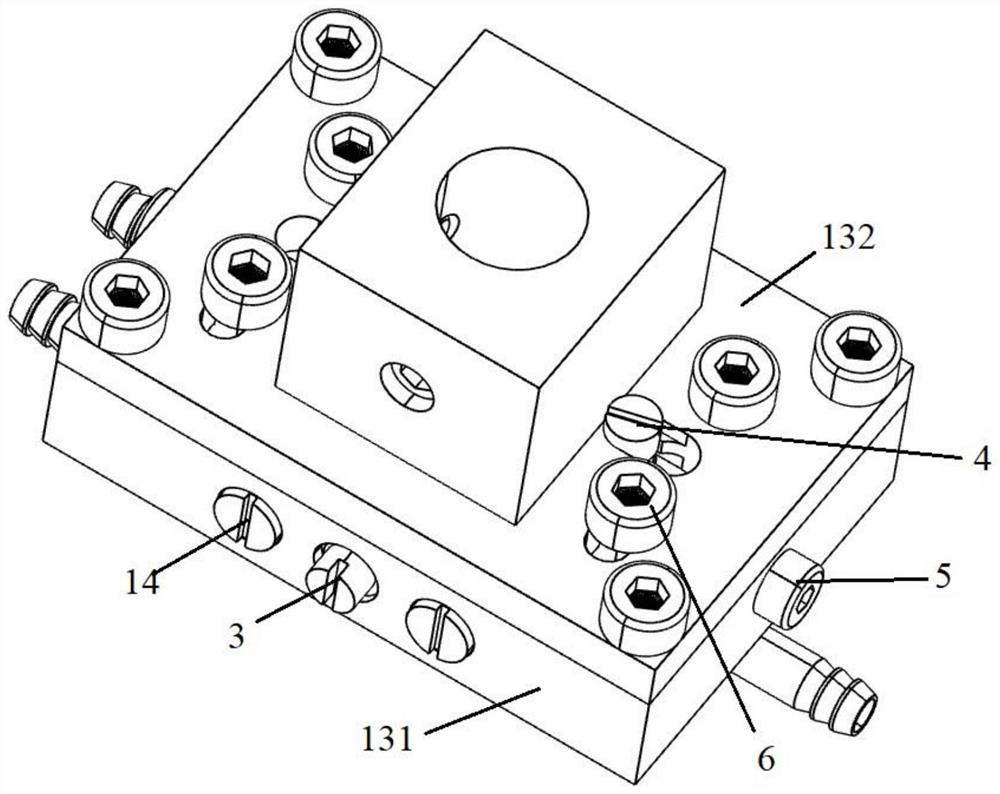

[0049] Embodiments of the present invention: as Figure 1-16 As shown, a labeling mechanism for chip heat dissipation stickers is disclosed. The labeling mechanism for heat dissipation stickers can absorb heat dissipation stickers under the action of vacuum adsorption holes and transfer the heat dissipation stickers to the position of the flexible substrate, and then dissipate heat dissipation. attached to a flexible substrate.

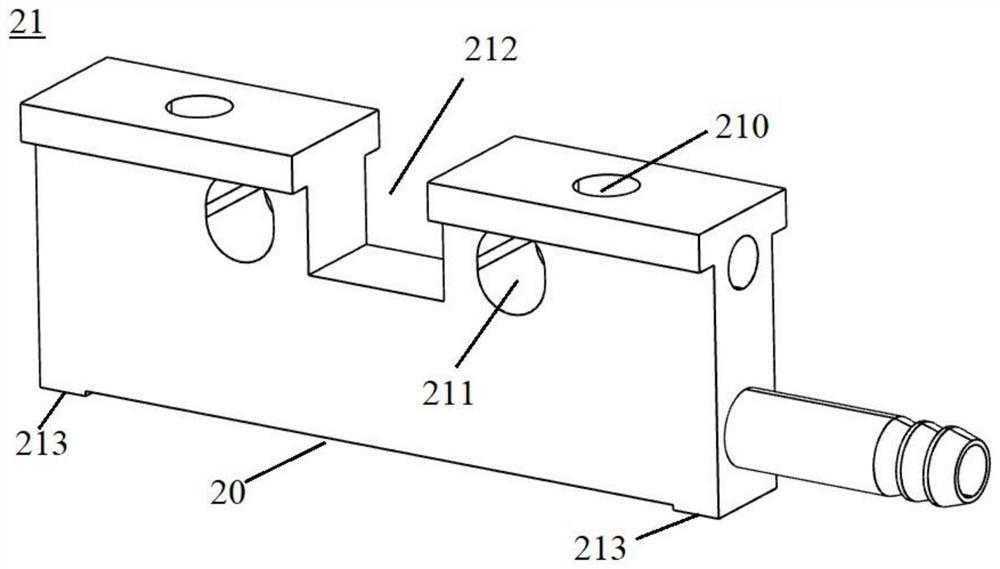

[0050] In the specific embodiment, the label-taking mechanism for the chip cooling paste includes a bracket 1, a header assembly 2 arranged on the bracket 1, an adjustment assembly 3 and a height adjustment member 4, and the header assembly 2 includes a middle The header 21 and the side header 22 arranged on the side of the middle header 21, the middle header 21 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com