Friction nanometer power generation device utilizing wind energy and wave energy

A nano power generation and friction power generation technology, applied in wind power generation, friction generator, ocean energy power generation and other directions, can solve the problem of low efficiency of wind energy and wave energy collection and conversion, and achieve the effect of improving utilization conversion rate and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

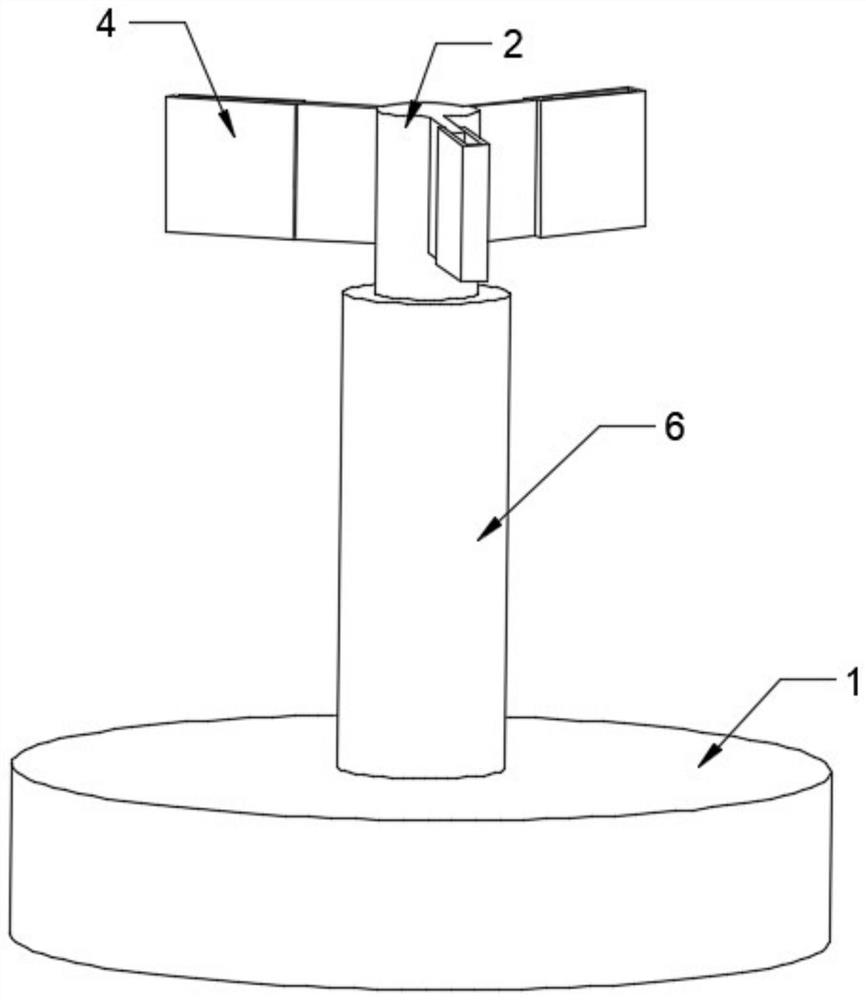

[0032] This embodiment discloses a frictional nanometer power generation device utilizing wind energy and wave energy. The device can be used to collect wave energy and wind energy at sea, and then convert the wave energy and wind energy into electrical energy for utilization.

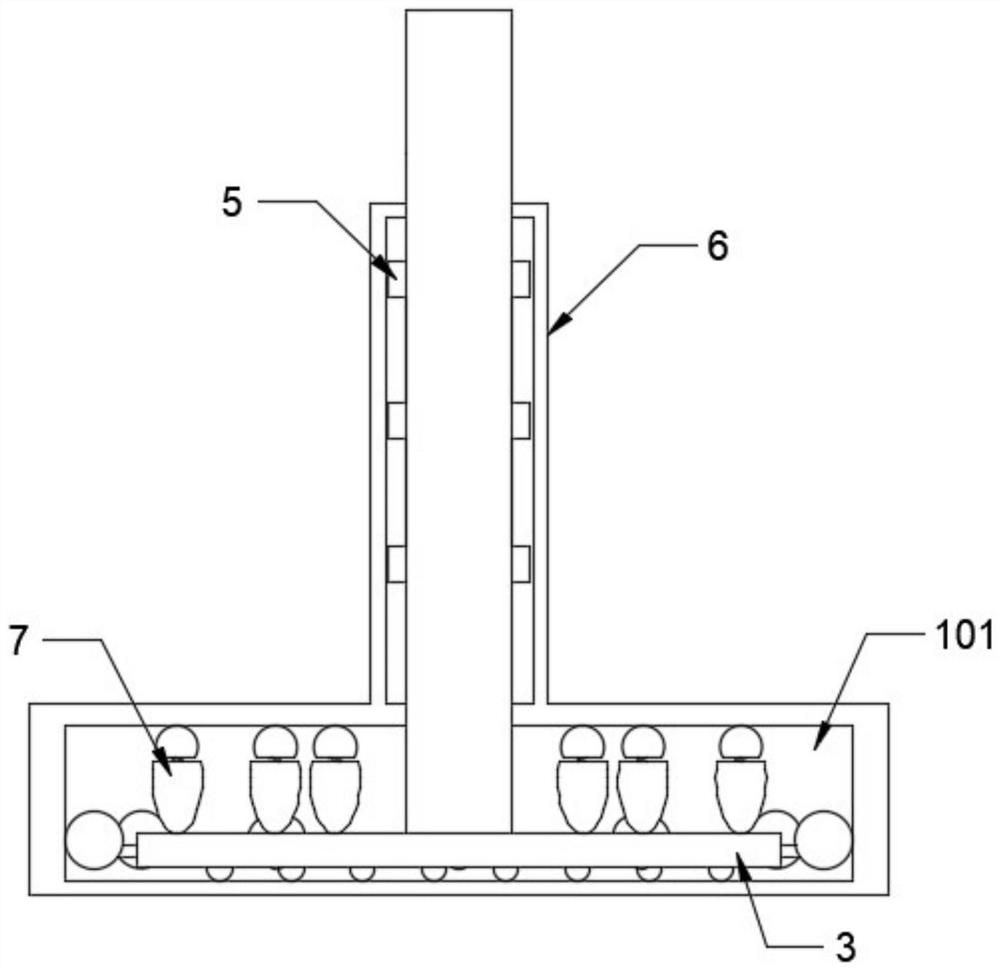

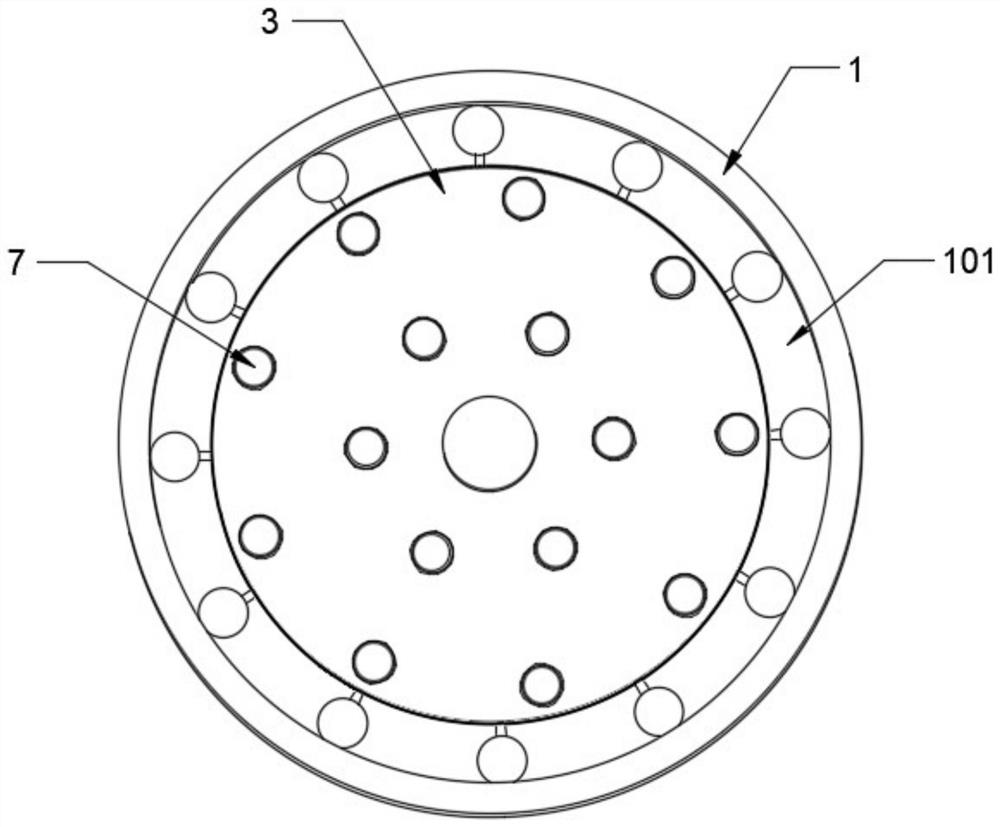

[0033] For this example, see Figure 1-3 , The specific structure of the triboelectric nanometer power generation device includes a chassis 1, a rotating shaft 2, a sleeve 6 and several ellipsoids 7. Of course, an electric contact module for storage may also be included. The specific description of each structure is as follows:

[0034] Wherein, a cylindrical cavity 101 is opened inside the chassis 1 . A friction layer 1 is provided on the inner wall of the cylindrical cavity. Of course, the external structure of the chassis 1 is not limited, such as cuboid, cube, cylinder and irregular structures, etc., in this embodiment, preferably, the external structure of the chassis 1 is a cylinder, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com