Hardware mechanical part rust prevention device capable of conveniently removing bubbles

A technology for mechanical parts and hardware, which is applied in the field of anti-rust devices for hardware and mechanical parts, can solve problems such as poor oil quality, poor stability, and easy rust, and achieve the goal of improving the quality of oil immersion, ensuring sufficiency, and improving stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

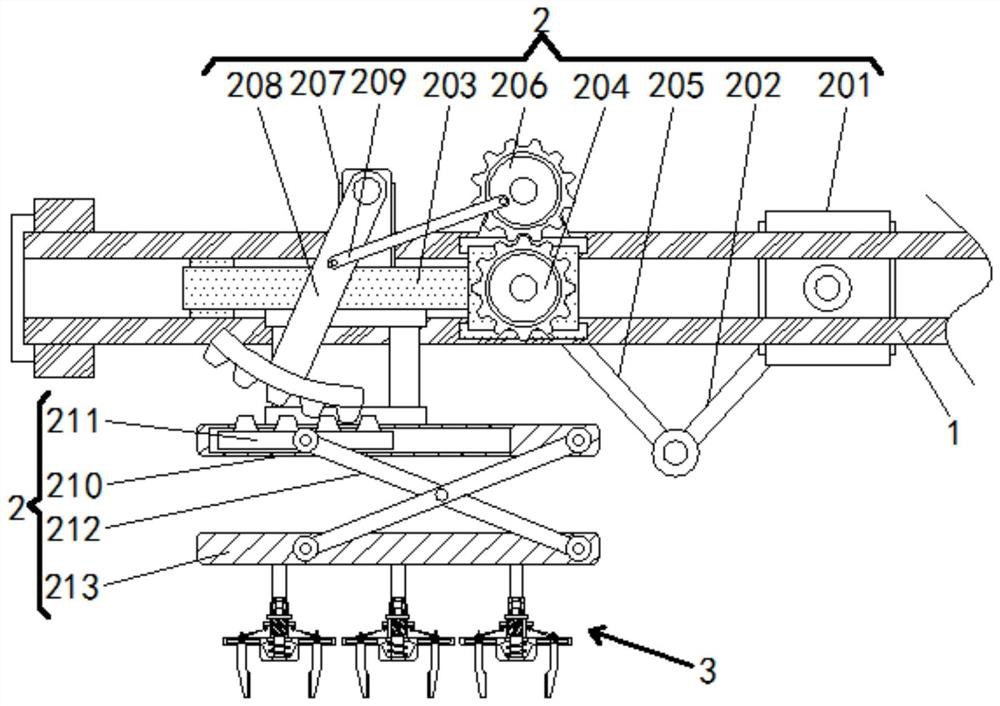

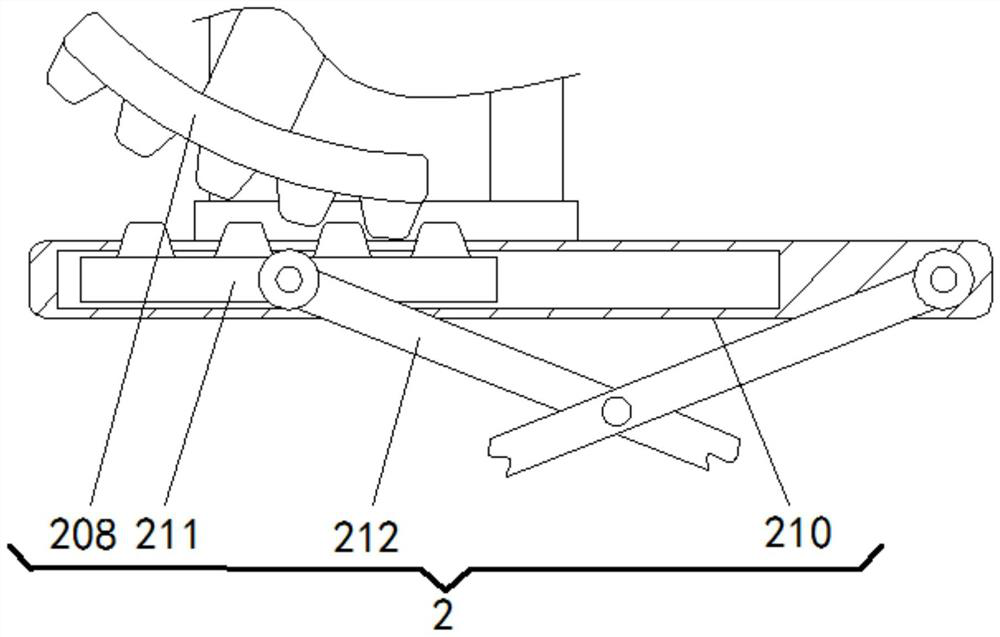

[0023] see figure 1 , 2 and 3, a rust-proof device for hardware and mechanical parts that is easy to remove air bubbles, including a sliding frame 1, the front end of the sliding frame 1 is movably connected with an adjustment mechanism 2, and the lower end of the adjustment mechanism 2 is fixedly connected with a positioning mechanism 3, and the adjustment mechanism 2 includes a positioning mechanism Block 201, first connecting rod 202, carrying bar 203, transmission gear 204, second connecting rod 205, driving gear 206, extension plate 207, swing rack 208, pole 209, positioning plate 210, tooth plate 211, hinged frame 212, movable plate 213, the rear end middle part of sliding frame 1 is fixedly connected with positioning block 201, the rear end of positioning block 201 is connected with first connecting rod 202 in rotation, the length of first connecting rod 202 and second connecting rod 205 are equal, Therefore, when the transmission gear 204 is driven to continue to rota...

Embodiment 2

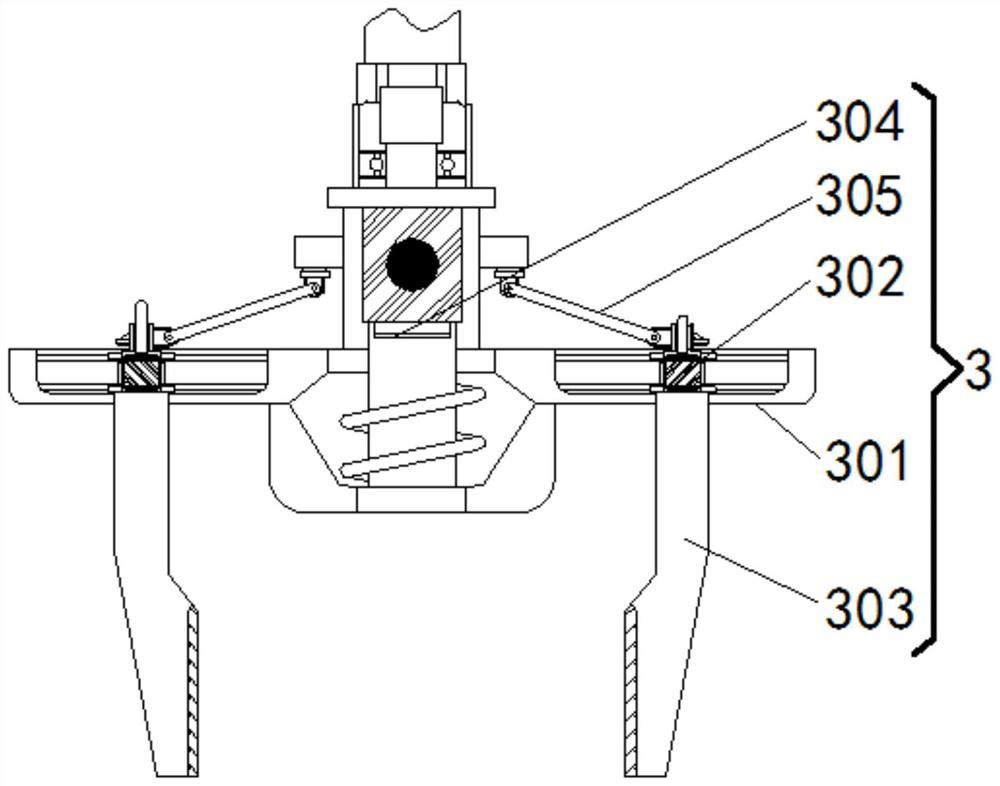

[0025] see figure 2 , a rust-proof device for hardware and mechanical parts that is convenient for removing air bubbles, including a sliding frame 1, the front end of the sliding frame 1 is movably connected with an adjustment mechanism 2, and the lower end of the adjustment mechanism 2 is fixedly connected with a positioning mechanism 3, and the positioning mechanism 3 includes a protective seat 301 , slider 302, abutment plate 303, telescopic column 304, pull rod 305, the protective seat 301 is fixedly connected to the lower end of the movable plate 213 and its quantity is designed to have at least three, so that a plurality of hardware parts can be respectively limited and lifted. While improving work efficiency, it can also prevent the parts from contacting each other to form interference. The left and right sides of the protective seat 301 are slidably connected with a slider 302, and the lower end of the slider 302 is fixedly connected with an abutment plate 303. The inn...

Embodiment 3

[0027] see Figure 1-4, a kind of antirust device for hardware and mechanical parts that is convenient for removing air bubbles, including a sliding frame 1, the front end of the sliding frame 1 is movably connected with an adjustment mechanism 2, and the adjustment mechanism 2 includes a positioning block 201, a first connecting rod 202, a carrying bar 203, a transmission Gear 204, second connecting rod 205, driving gear 206, extension plate 207, swing rack 208, pole 209, positioning plate 210, tooth plate 211, hinged frame 212, movable plate 213, the rear end middle part of sliding frame 1 is fixed A positioning block 201 is connected, and the rear end of the positioning block 201 is rotatably connected with a first connecting rod 202. The lengths of the first connecting rod 202 and the second connecting rod 205 are equal, so that when the transmission gear 204 is driven to rotate continuously, the first connecting rod 202 Restricted by the connecting rod 202 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com