Hard super-large plate lifting appliance

A super-large and spreader technology, applied in the field of spreaders, can solve the problems of inconvenient cost, different hard super-large disks, and increase the labor intensity of operators, so as to improve production efficiency, avoid pipe deformation, and simplify the operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

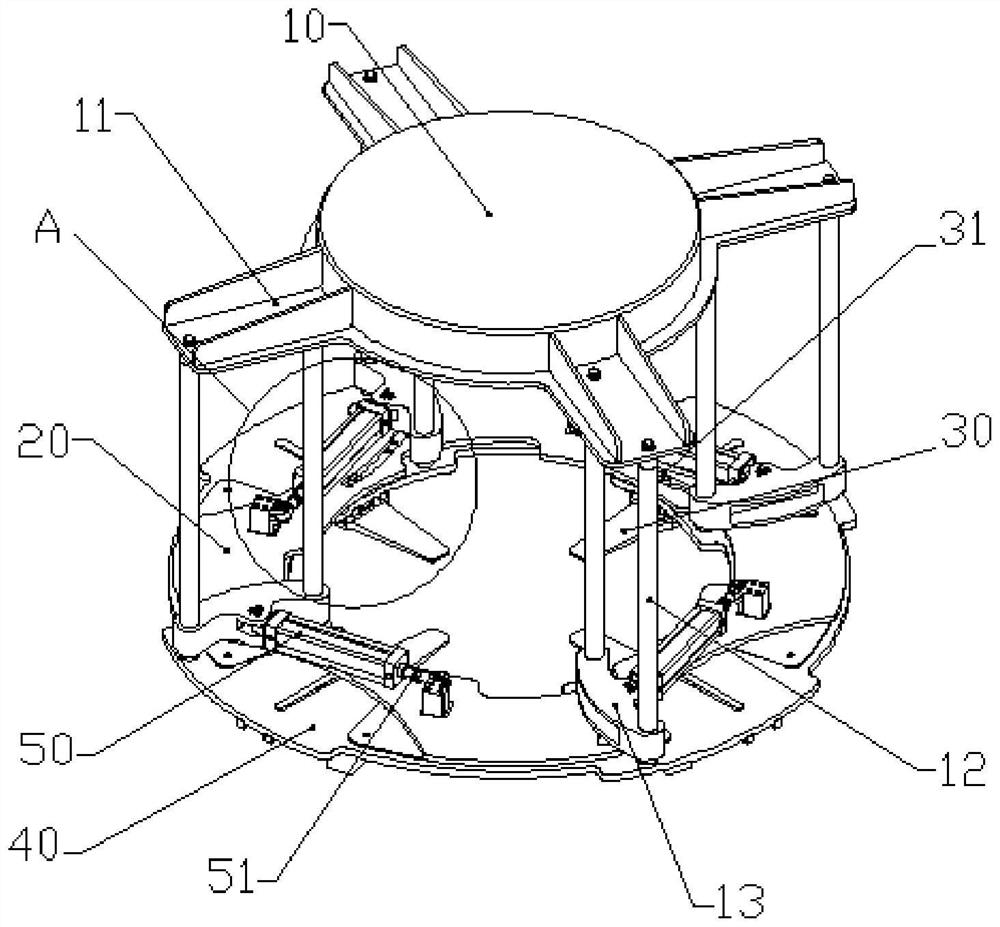

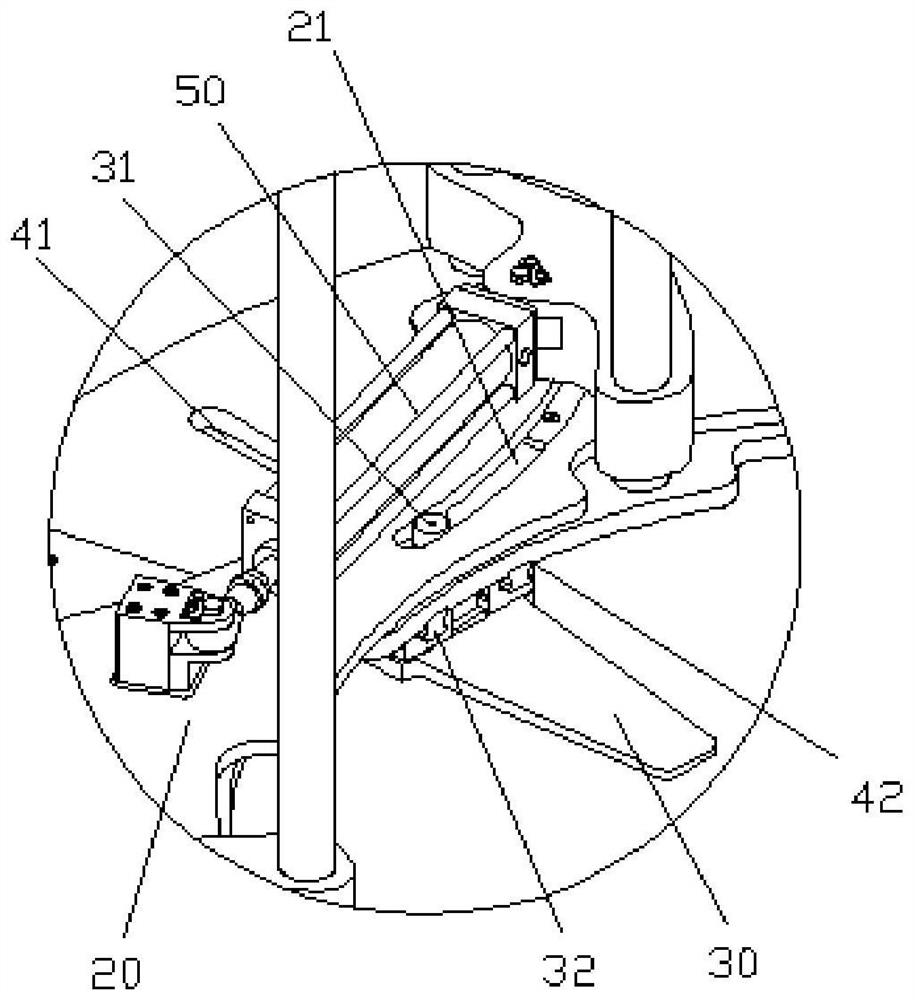

[0018] Example: such as figure 1 with figure 2 As shown, a kind of hard super-large dish spreader includes a hanger 10, a liner 40 and several support units, and the support unit includes a turntable 20, a long tongue plate 30 and a drive assembly, and the hanger 10 is connected with the The liner 40 is fixedly connected, and a cavity is opened inside the liner 40 , the turntable 20 is rotatably mounted on the liner 40 , and the long tongue 30 is slidably mounted on the liner 40 , so The drive assembly is connected to the turntable, and when the drive assembly drives the turntable to rotate, the turntable 20 can drive the long tongue plate 30 to extend out of the cavity of the liner or retract the liner. The liner 40 is located below the hanger 10, and the middle part of the liner is a cavity. Usually, the long tongue 30 is retracted in the liner. During operation, the external equipment lifts the hanger 10 and sets the spreader on the hard surface. The super-large hard dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com