Thin-walled pipe bending device

A pipe bending device and a technology for thin-walled pipes, which are applied in the field of pipe processing, can solve the problems of uneven surface of pipes and easy deformation, and achieve the effects of avoiding stretching, improving stretching ability, and avoiding pipe deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments and reference numerals:

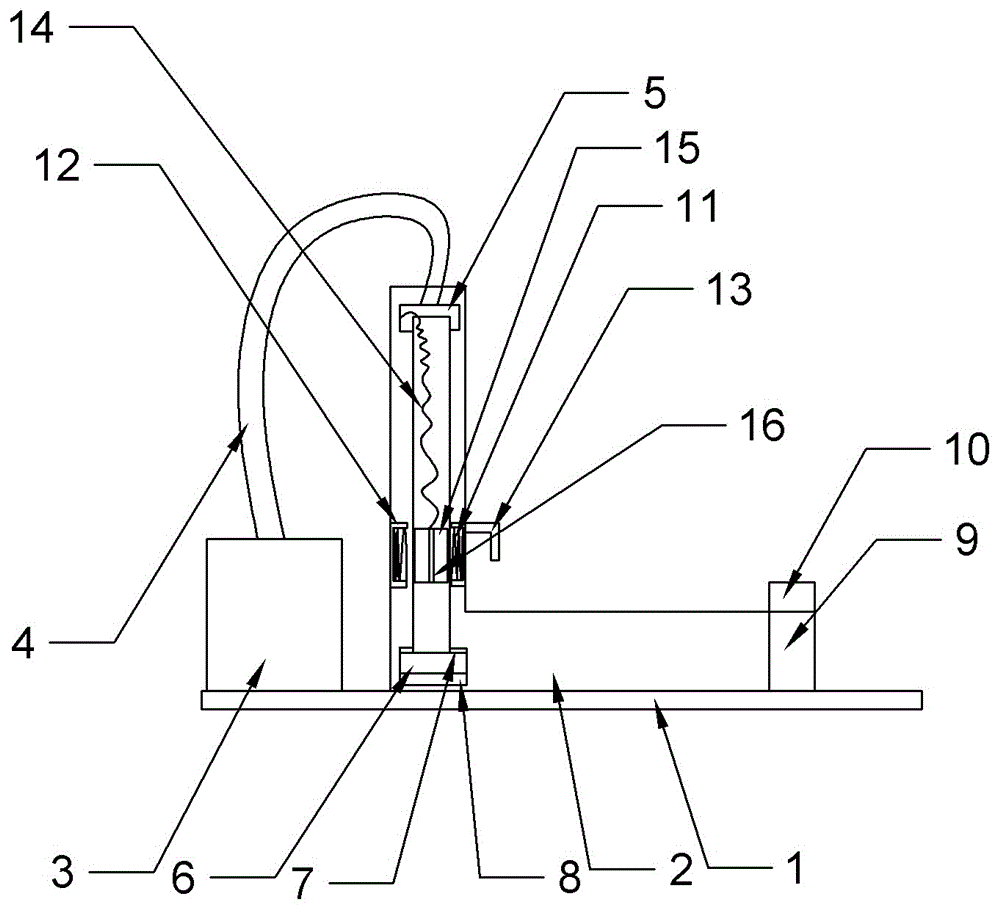

[0016] The reference signs in the drawings of the description include: workbench 1, forming mold 2, gas tank 3, hose 4, fixed cover 5, stretch cover 6, elastic sleeve 7, iron sheet 8, electromagnet 9, controller 10 , hot water pipe 11, housing 12, handle 13, spring 14, air bag 15, channel 16.

[0017] as attached figure 1 Shown: the pipe bending device for thin-walled pipes, including a workbench 1, a molding die 2 is fixedly installed on the top of the workbench 1, and the molding die 2 has an L-shaped structure, wherein the horizontal part and the vertical part of the molding die 2 are connected by threads , the pipe is stretched into the vertical part by the upper end of the molding die 2 . One side of the molding die 2 is provided with an air tank 3, the gas tank 3 is connected to the pipe through a hose 4, and one end of the hose 4 close to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com