Chlorosulfenyl hydride superconducting material and preparation method thereof

A chlorine-sulfur-based hydride, superconducting material technology, applied in sulfur and halogen compounds, the usage of superconducting elements, superconducting devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

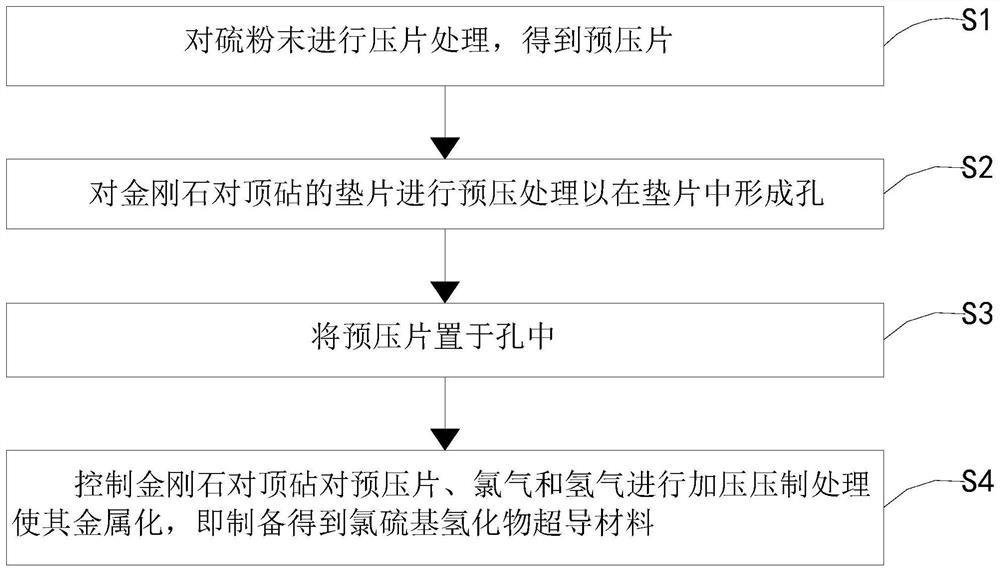

[0035] Based on the same inventive concept, the embodiment of the present application also provides a method for preparing a chlorosulfanyl hydride superconducting material, including the following steps:

[0036] Provide sulfur powder, chlorine and hydrogen;

[0037] Sulfur powder, chlorine gas and hydrogen gas are pressurized and pressed to make them metallized to obtain the chlorosulfur-based hydride superconducting material.

[0038] In some embodiments, the pressure of the pressurized pressing treatment is 90-200 GPa; the molar ratio of sulfur powder, chlorine gas and hydrogen gas is (1-2):(0.5-1):6.

[0039] Specifically, the superconducting transition temperature (that is, the superconducting critical temperature) that a superconducting material can achieve can be obtained by solving the Eliashberg equation. Usually, because it is too difficult to solve the Elieberger equation, the McMillan equation modified by Daines (equation 1 below) or the McMillan equation modifie...

Embodiment 1

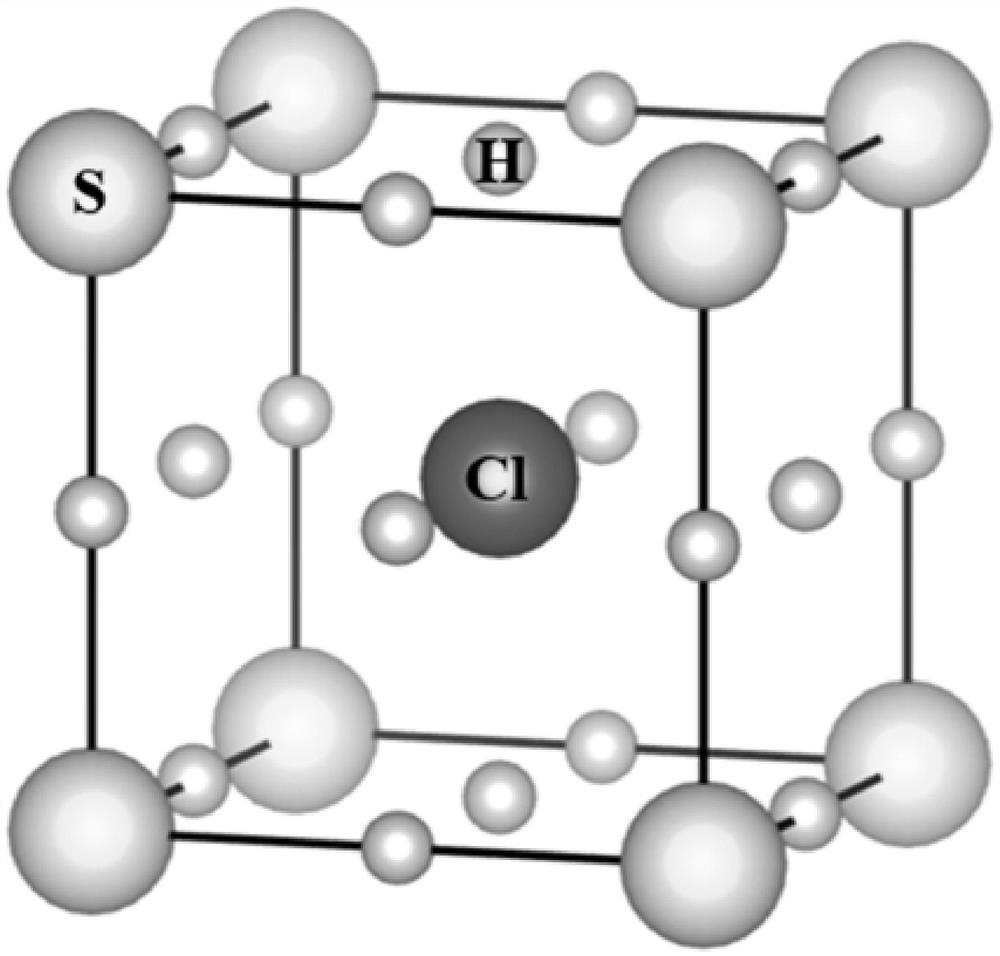

[0061] The embodiment of the present application provides a chlorosulfanyl hydride superconducting material whose chemical formula is ClSH 6 .

[0062] The preparation method of the above-mentioned chlorosulfur-based hydride superconducting material comprises the following steps:

[0063] S1. Perform tableting treatment on the sulfur powder to obtain pre-pressed tablets;

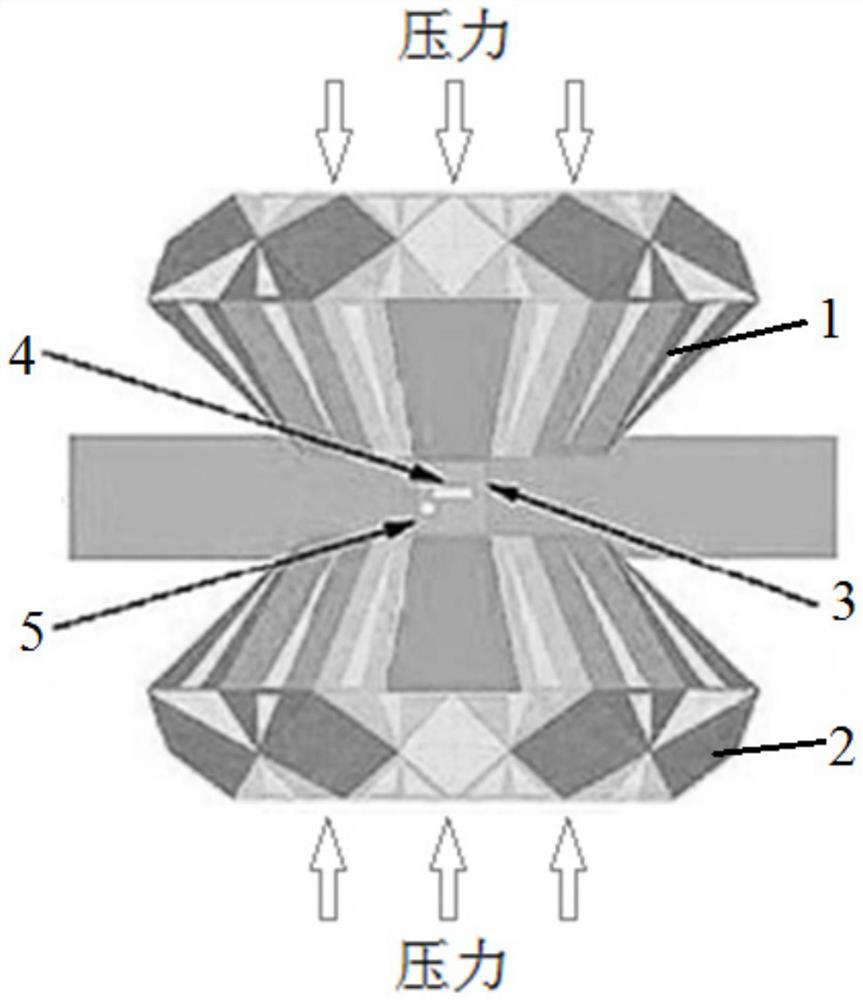

[0064] S2, pre-pressing the rhenium gasket of the diamond anvil to form holes in the gasket;

[0065] S3, placing the pre-pressed sheet in the hole;

[0066] S4. Use the gas sealing device to fill chlorine and hydrogen into the diamond counter-anvil, and control the diamond counter-anvil to pressurize the pre-pressed sheet, chlorine gas and hydrogen to make it metallized, and prepare a chlorosulfur-based hydride superconductor Material.

[0067] Among them, the molar ratio of sulfur powder, chlorine gas and hydrogen gas is 2:1:6, and the pressure controlled by pressurization is 90GPa.

[0068] The cryst...

Embodiment 2

[0072] The embodiment of the present application provides a chlorosulfanyl hydride superconducting material whose chemical formula is ClSH 6 .

[0073] The preparation method of the above-mentioned chlorosulfur-based hydride superconducting material comprises the following steps:

[0074] S1. Perform tableting treatment on the sulfur powder to obtain pre-pressed tablets;

[0075] S2, pre-pressing the rhenium gasket of the diamond anvil to form holes in the gasket;

[0076] S3, placing the pre-pressed sheet in the hole;

[0077] S4. Use the gas sealing device to fill chlorine and hydrogen into the diamond counter-anvil, and control the diamond counter-anvil to pressurize the pre-pressed sheet, chlorine gas and hydrogen to make it metallized, and prepare a chlorosulfur-based hydride superconductor Material.

[0078] Among them, the molar ratio of sulfur powder, chlorine gas and hydrogen gas is 2:1:6, and the pressure controlled by pressurization is 200GPa.

[0079] The crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com