Method for laying ground tracks supported at intervals

A laying method and track technology, which is applied to track, track laying, track maintenance, etc., can solve the problems of heavy load, high installation tightness between rail and supporting steel plate, and difficult construction, so as to eliminate installation deviation and save strength Effects of waiting periods, efficient track laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Various embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

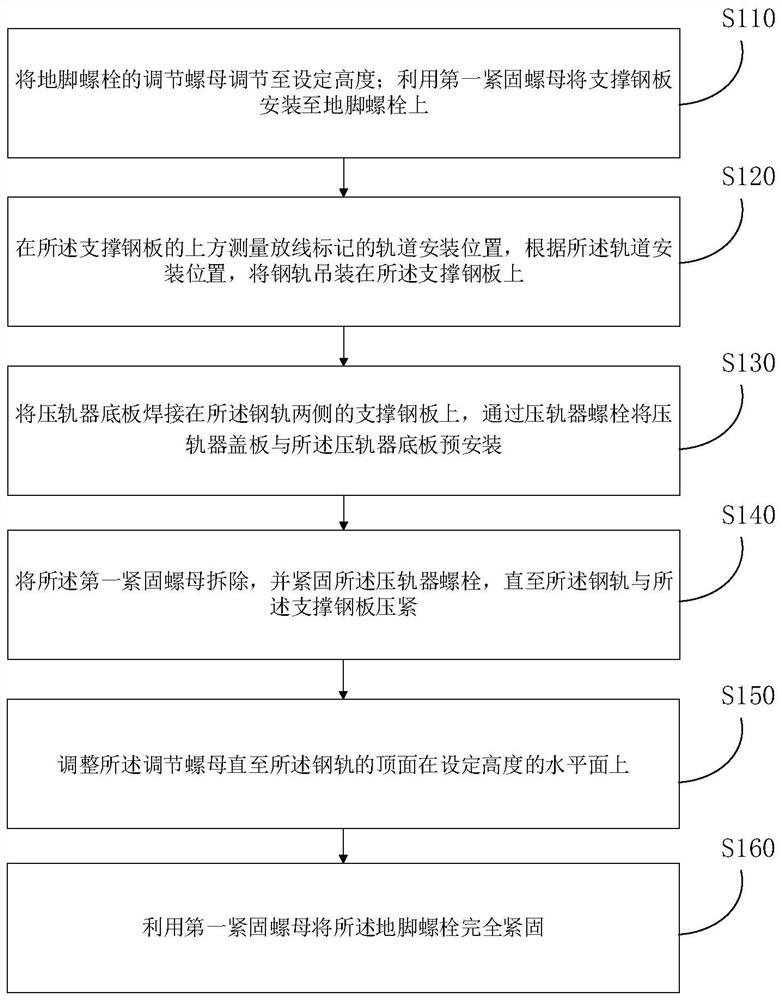

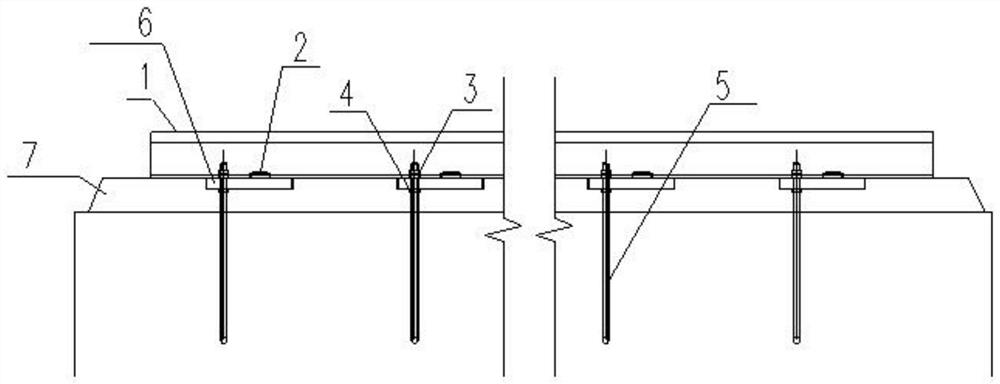

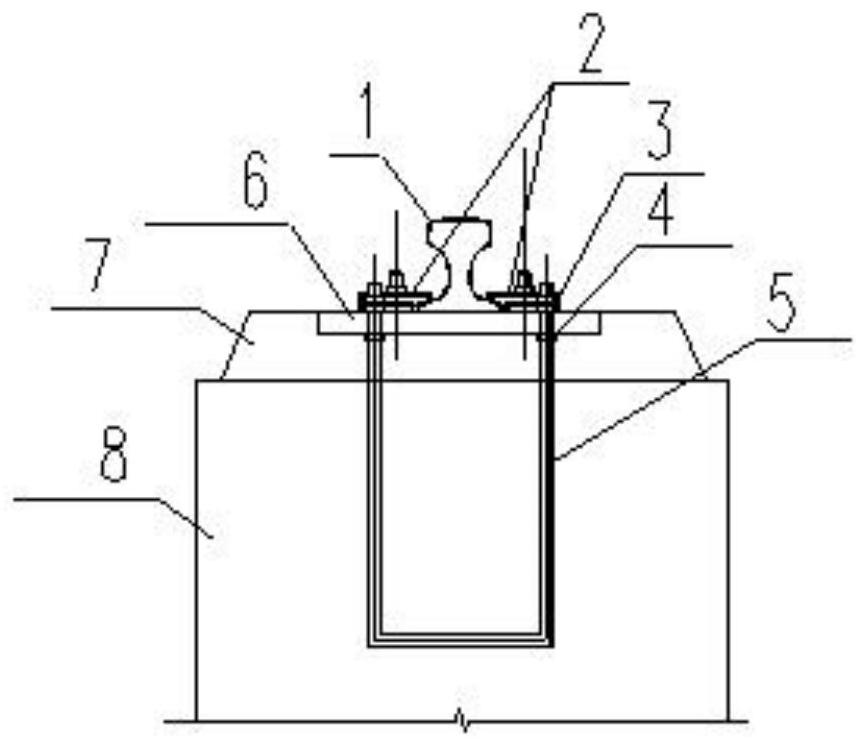

[0034] figure 1 The logical principles of the spaced-supported ground track laying method are described as a whole. Specifically, figure 1 It is a schematic diagram of the logical principle of the ground track laying method with spaced supports according to the embodiment of the present invention.

[0035] The ground track laying method with interval support includes steps S110-S160.

[0036] S110 , adjusting the adjusting nut 4 of the anchor bolt 5 to a set height; using the first fastening nut 3 to pre-install the anchor bolt 5 on the supporting steel plate 6 .

[0037] Specifically, the adjusting nut 4 of the anchor bolt 5 is adjusted to a uniform elevation, then after the bolt holes of each supporting steel plate 6 pass through the anchor bolt 5, a fastening nut 3 above the supporting steel plate 6 is screwed in earlier, and the Each supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com