Plate rolling machine with anti-springback protection function

A plate rolling machine and anti-rebound technology, applied in the direction of cleaning method using gas flow, dust removal, forming tools, etc., can solve the problems of lack of lubrication structure, lack of anti-rebound structure, lack of auxiliary loading and unloading structure, etc., to achieve The effect of convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

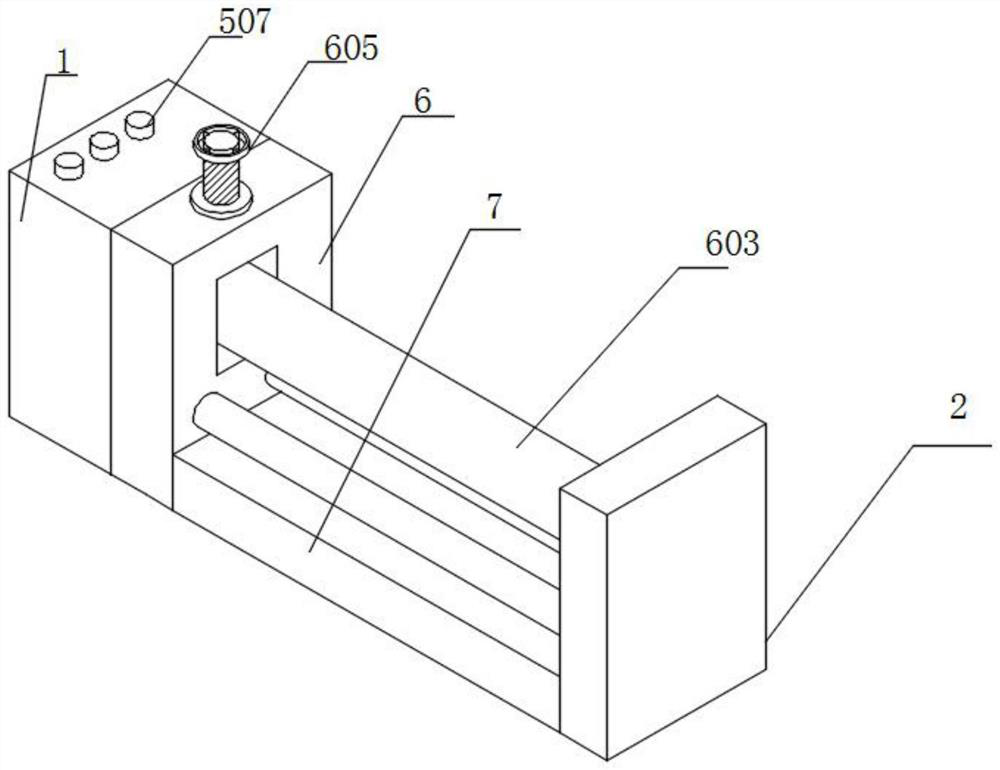

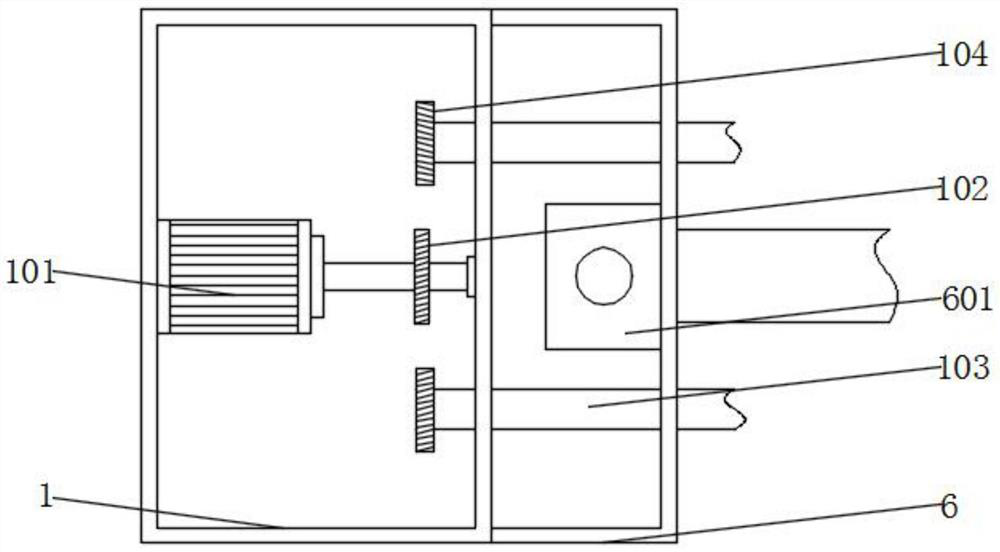

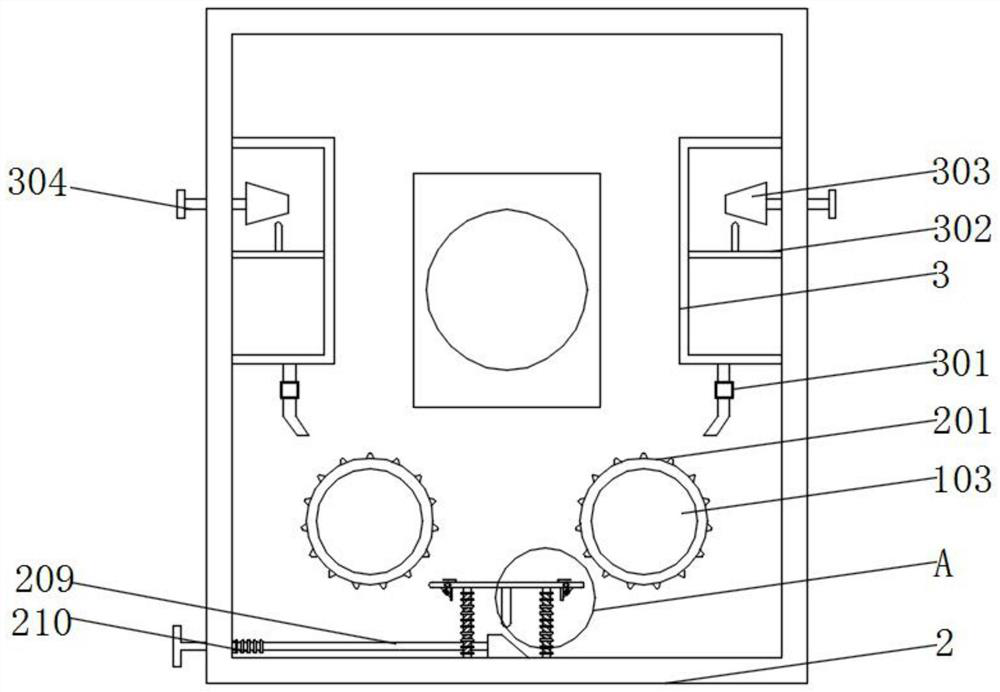

[0045] Example 2: see figure 1 , image 3 and Figure 4 , an embodiment provided by the present invention: a plate bending machine with anti-rebound protection, a ratchet 201 is installed on the inner wall of the holder 2, a spring column 202 is installed on the inner bottom wall of the holder 2, and the spring column 202 Limit plate 203 is installed on the top, and support column 204 is installed on the bottom of limit plate 203, and the two ends of limit plate 203 are all equipped with movable plate 206, and the top of limit plate 203 is equipped with L-shaped limit plate 205, and the limit The bottom of the plate 203 is equipped with a riser 207, the outer wall of the riser 207 is equipped with a first spring 208, and one end of the first spring 208 is connected with the bottom of the movable plate 206, and the outer wall of the fixture 2 is equipped with a moving bar 209, which moves The outer wall of the rod 209 is surrounded by a second spring 210, and a wedge block is...

Embodiment 3

[0046] Example 3: See Figure 5 and Figure 8 , an embodiment provided by the present invention: a plate rolling machine with anti-rebound protection, a lubricating pipe is installed on the bottom of the lubricator 3, a pressure valve 301 is installed on the outer wall of the lubricating pipe, and a pressure valve 301 is installed on the inner wall of the lubricator 3 Extrusion plate 302, extrusion rod is installed on the top of extrusion plate 302, bolt 304 is installed through the outer wall of lubricator 3, extrusion block 303 is installed on one end of bolt 304, lubricating cylinder 401 is installed on the bottom of lubrication box 4, The inner bottom wall of the lubricating cylinder 401 is installed with a striking rod 402, the outer wall of the striking rod 402 is surrounded by a third spring 403, the inner wall of the lubricating cylinder 401 is equipped with a sealing block 404, and the inner top wall of the lubricating cylinder 401 is equipped with a fourth spring. 4...

Embodiment 4

[0047] Example 4: See Figure 7, an embodiment provided by the present invention: a plate bending machine with anti-rebound protection, a gear shaft 501 is installed on the inner wall of the water level gauge 5, a conductive rod 502 is installed on the outer wall of the gear shaft 501, and the top of the water level gauge 5 A gear plate 503 is installed through it, the outer wall of the gear plate 503 is surrounded by a No. 2 spring 504, a floating ball 505 is installed on the top of the gear plate 503, a conductive plate 506 is installed on the inner bottom wall of the water level gauge 5, and the top of the drive box 1 is installed There is a warning light 507, the floating ball 505 inside the water level gauge 5 rises or falls with the liquid level, drives the gear plate 503 to move, the gear plate 503 drives the gear shaft 501 to rotate, when the content of lubricating oil decreases, the conductive rod 502 and the conductive The contact of the plate 506 causes the warning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com