A control system and method for energy-saving and non-stop maintenance of vacuum pump

A control system and control method technology, applied in pump control, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve the problems of affecting dust removal and filtering effect, weak permeability, small filtering area, etc., to prevent safety Hidden danger, good stability, easy to clean the filter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

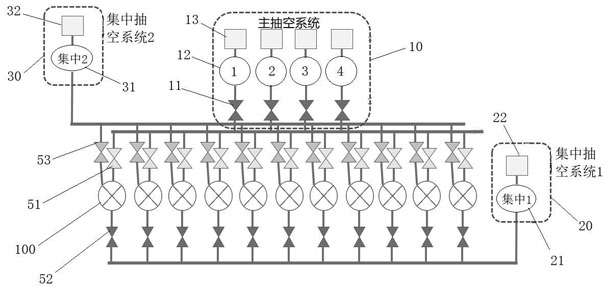

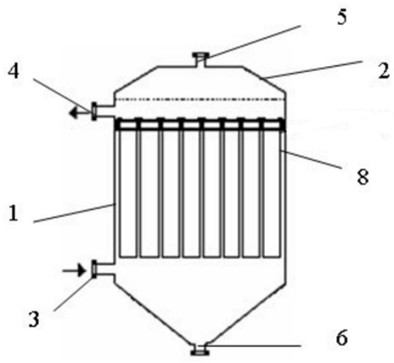

[0029] Below in conjunction with the accompanying drawings in the embodiments of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely

[0030] It should be noted that all directional indications (such as up, down, left, right, front, back...) in the embodiments of the present invention are only used for

[0031] In addition, in the present invention, the description related to "first", "second", etc. is only for the purpose of description, and should not be construed as referring to

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com