Photovoltaic panel underframe capable of automatically calibrating light source

A photovoltaic panel and automatic calibration technology, applied in the field of chassis, can solve the problems of low working efficiency of photovoltaic panels, easy accumulation of dust or debris, etc., to achieve the effect of avoiding residual dust and good dust protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

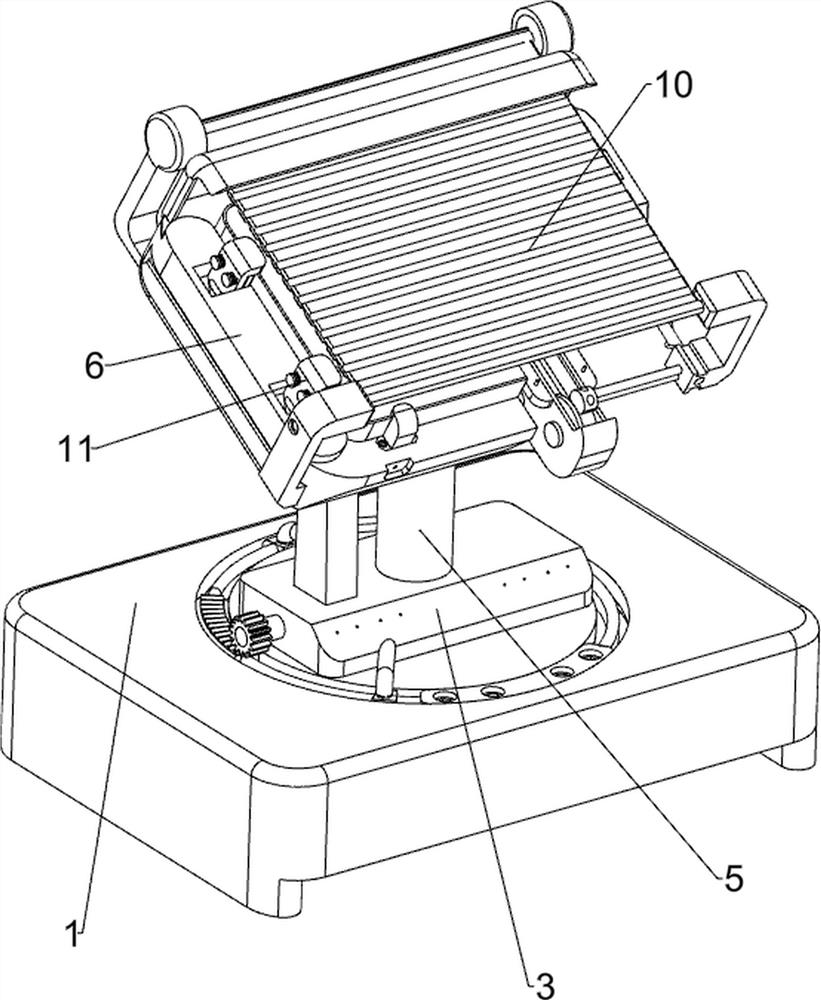

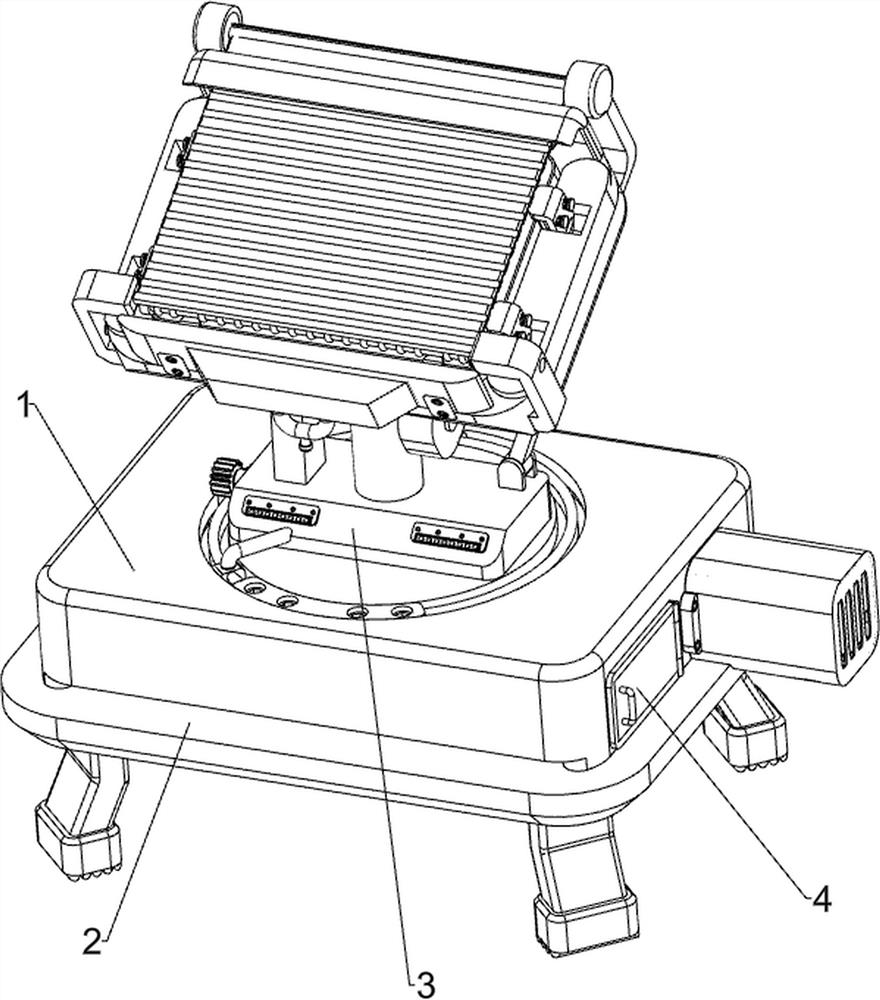

[0040] A photovoltaic panel chassis that automatically calibrates the light source, such as Figure 1-Figure 4 As shown, it includes a supporting bottom box 1, a fixed bottom plate 2, a rotating base 3, a first photoelectric sensor 41, a second photoelectric sensor 42, a vertical shaft 5, an installation bottom box 6, a photovoltaic panel 7, a driving mechanism 8 and a support Mechanism 9, the bottom of the support bottom box 1 is fixedly connected with a fixed bottom plate 2, the middle of the support bottom box 1 is rotated and provided with a vertical shaft 5, the bottom of the vertical shaft 5 is fixedly connected with a swivel seat 3, and the left side of the front side of the swivel seat 3 is fixedly connected There is a first photoelectric sensor 41, a second photoelectric sensor 42 is fixedly connected to the right part of the front side of the swivel base 3, and the top of the vertical rotating shaft 5 is connected with the installation bottom box 6 by bolts, and the i...

Embodiment 2

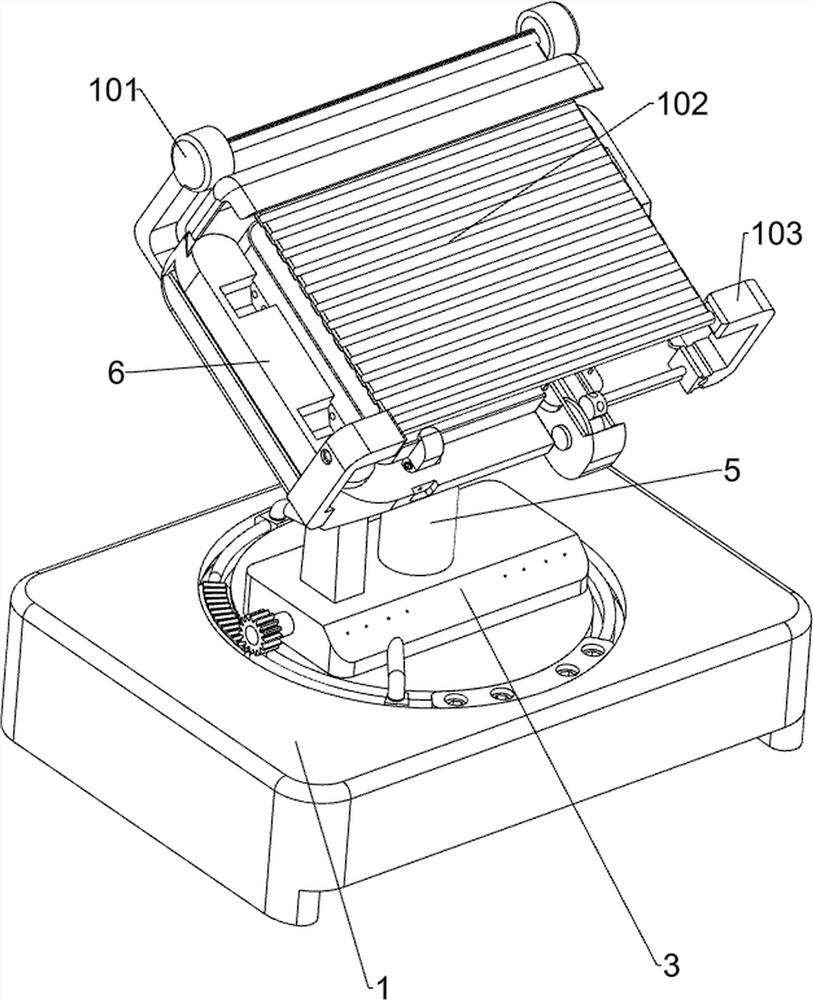

[0045] On the basis of Example 1, such as Figure 5-Figure 8 As shown, a dust-proof mechanism 10 is also included, and the dust-proof mechanism 10 includes a fixed short post 101, a dust-proof cloth 102, a lateral movement vertical block 103, a first positioning block 104, a second positioning block 105, an iron sliding rack 106, positioning magnetic frame 107, fixed guide rail 108, reversing shaft 109, driven gear 1010, transmission belt assembly 1011, third positioning block 1012, positioning belt assembly 1013, first connecting frame 1014, first reset guide rod 1015, The first back-moving spring 1016, the slotted rotating shaft 1017, the scroll spring 1018 and the fixed cross bar 1019, the left and right sides of the upper part of the rear side of the bottom box 6 are installed symmetrically and are connected with the fixed stub 101 by means of bolts, and the bottom box 6 left and right sides are all fixed. Connected with a first reset guide rod 1015, the first reset guide ...

Embodiment 3

[0050] On the basis of embodiment 1 and embodiment 2, such as Figure 13-Figure 15 As shown, a cleaning mechanism 12 is also included, and the cleaning mechanism 12 includes a cleaning sponge column 121, a first pressure sensor 122, a guide frame 123, a water pump 124, a water inlet pipe 125, a liquid replenishment pipe 126, a liquid storage barrel 127 and a liquid outlet pipe 128 A cleaning sponge column 121 is arranged in a rotating manner between the front parts of the horizontal movement vertical block 103, and the cleaning sponge column 121 can realize cleaning of the photovoltaic panel 7, and a first pressure sensor 122 is fixedly connected to the lower side of the left part of the installation bottom box 6, and the installation bottom box 6 The lower part is connected with a guide frame 123 by means of bolts, and the left side of the upper part of the installation bottom box 6 is connected with a water pump 124 by means of bolts. A water inlet pipe 125 is connected betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com