High-brightness surface defect detection device based on micro-lens array projection

A micro-lens array and defect detection technology, applied in the field of defect detection, can solve the problems of unclear image boundary, limited projection distance, large equipment volume, etc., and achieve the effect of reducing the company's inspection cost, improving product quality, and long projecting distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

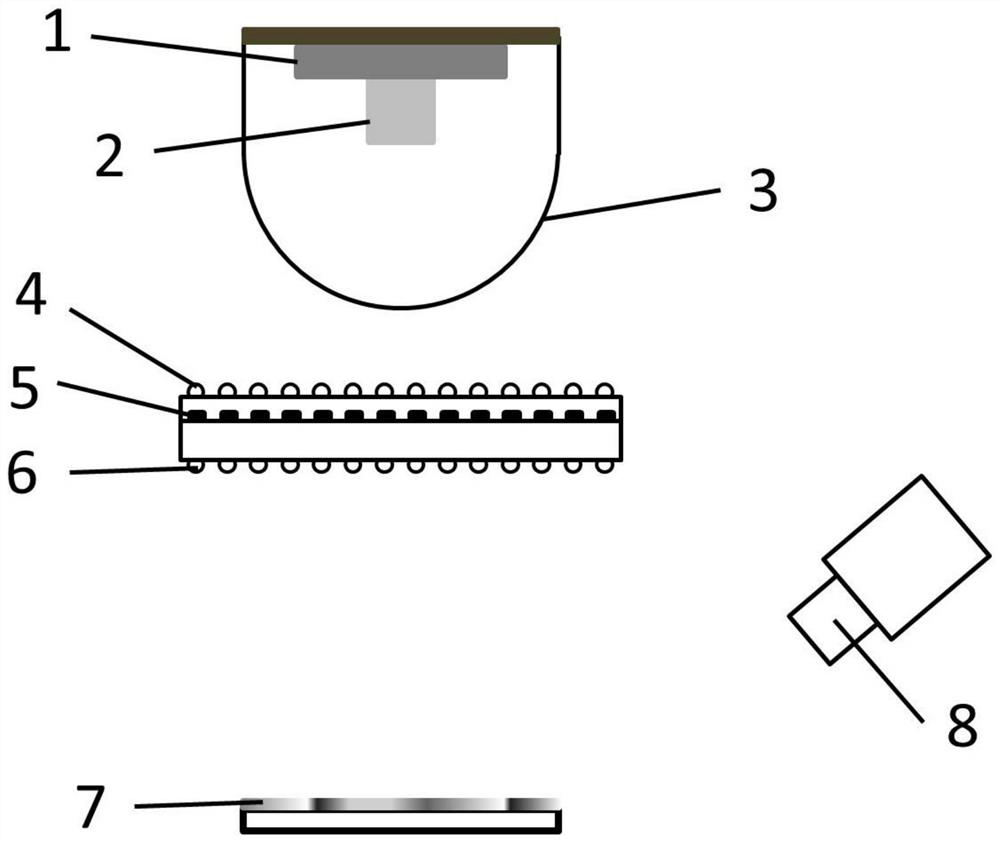

[0026] refer to figure 1 , a high-brightness surface defect detection device based on microlens array projection provided in this embodiment includes a circuit board 1, a light source 2, a collimator lens 3, a microlens array, a sample to be tested 7, and a camera 8; the light source 2 is installed on On the circuit board 1, the light source 2 is also equipped with a collimating lens 3, which can convert the scattered light emitted by the light source 2 into parallel light, and the light generated by the light source 2 is irradiated onto the sample 7 to be tested after passing through the microlens array;

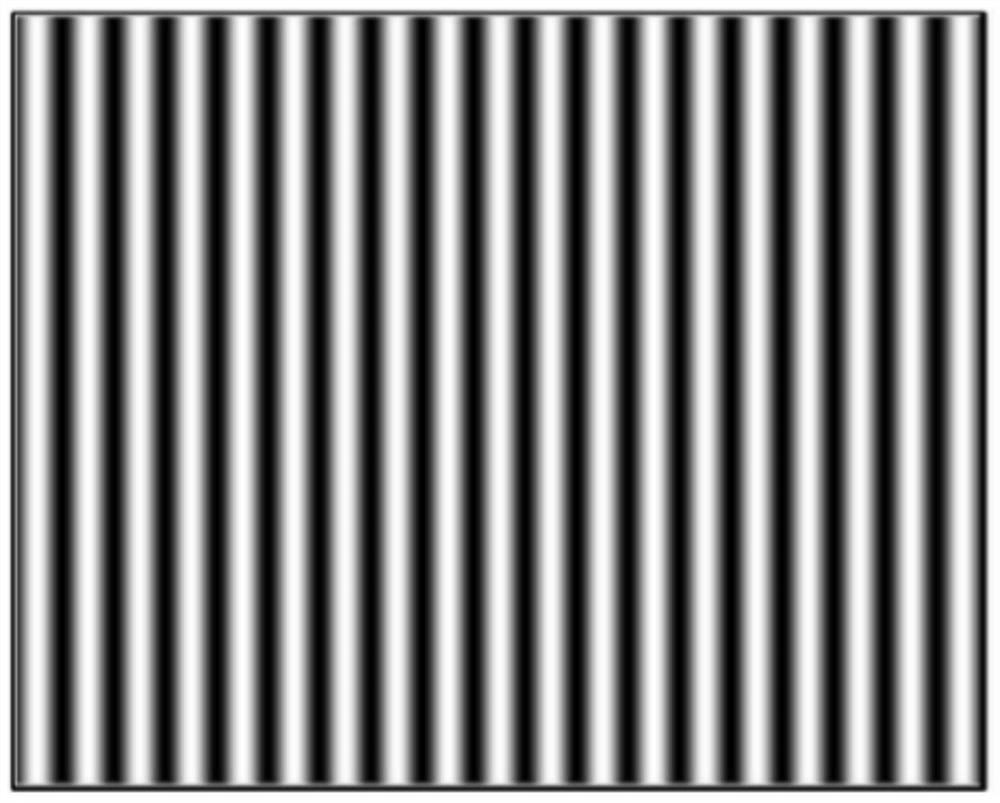

[0027] The microlens array combination comprises the first microlens array 4 and the second microlens array 6 and the stripe micropattern light-shielding layer 5 between the first lens array 4 and the second lens array 6, the first microlens array 4, the stripe micro The pattern light-shielding layer 5 and the second microlens array 6 are placed in sequence along the optica...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap