Swing type laser welding device capable of finely adjusting focal length

A laser welding and swinging technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of defocus, welding spot size, energy unevenness, etc., achieve parallel exit light, avoid defocus problems, The effect of energy uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

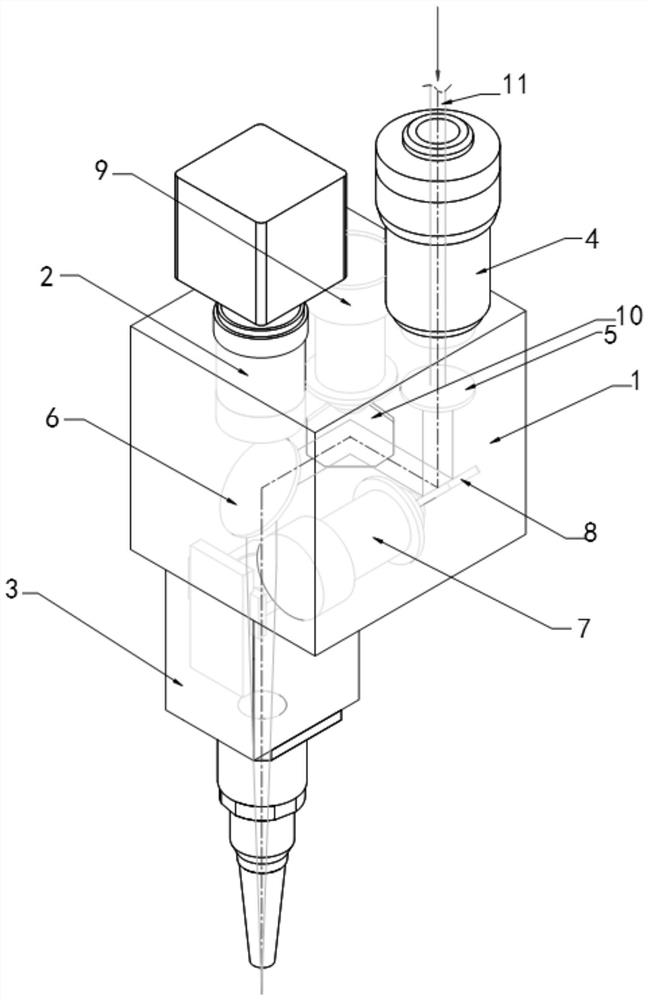

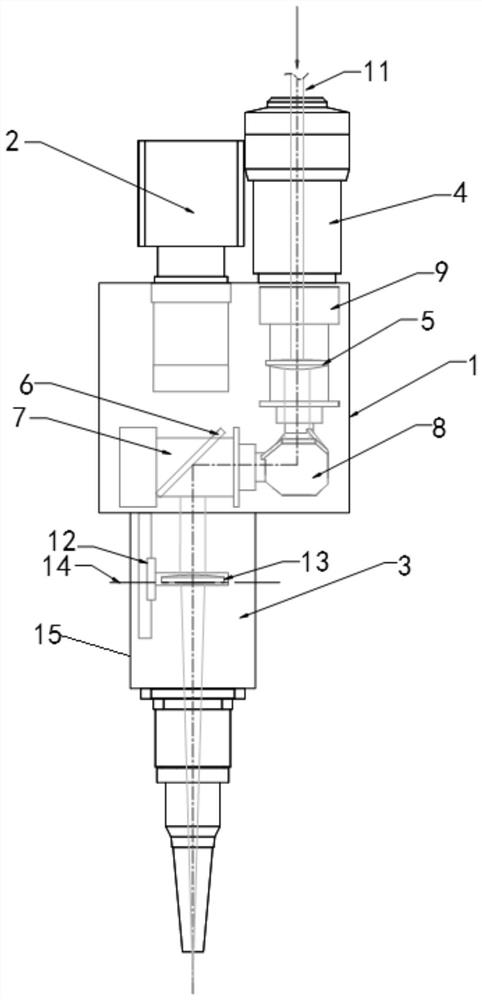

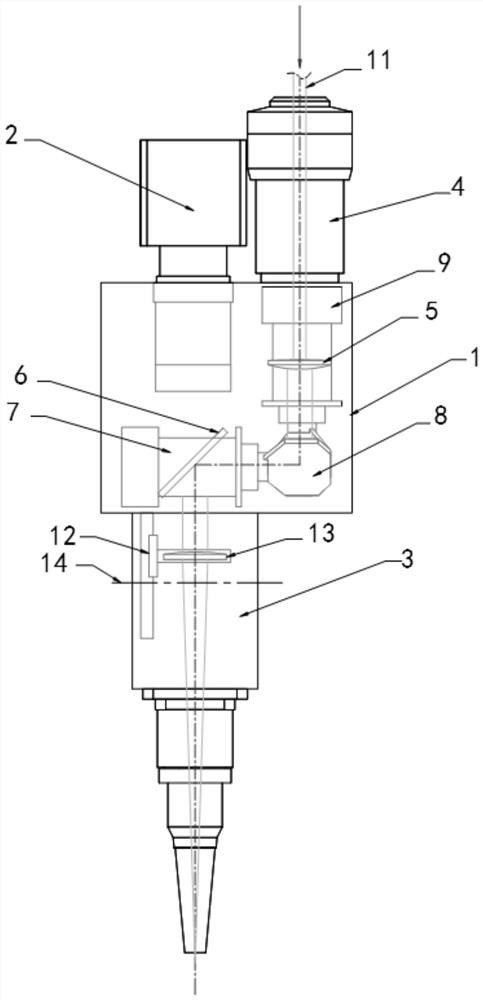

[0024] The invention provides a swing type laser welding device capable of finely adjusting the focal length, the structure is as follows figure 1 As shown, it includes a hollow support 1, a CCD camera 2 and a QBH fiber interface 4 are respectively arranged on the hollow support 1, and a laser focusing assembly 3 is arranged at the bottom of the hollow support 1 and directly below the CCD camera 2, and the hollow support 1 is provided with an X drive motor 7, a Y drive motor 9, a beam expander 5, and a fixed beam splitter 6. The X drive motor 7 and the Y drive motor 9 are respectively arranged on two different surfaces of the hollow support 1 and are different from each other. The surface is vertical, and the optical angle of the rotating shafts of X driving motor 7 and Y driving motor 9 does not exceed 24°. The mirror reflector 10, the beam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com