Protective cover structure for machining equipment

A technology of mechanical processing and protective cover, which is applied in the field of protective cover, can solve the problems of gaps in the closure, occupying space, and ineffective closing between sliding doors, etc., so as to increase airtightness, increase airtightness and durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

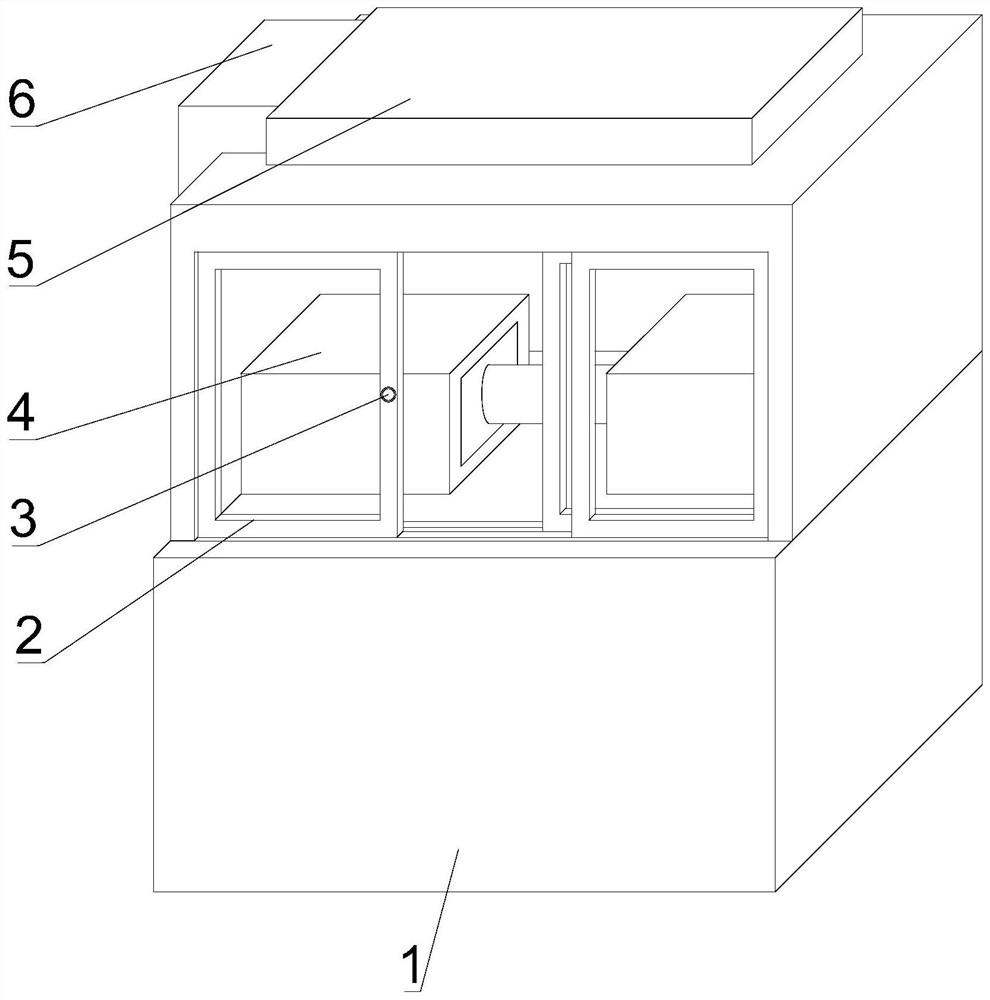

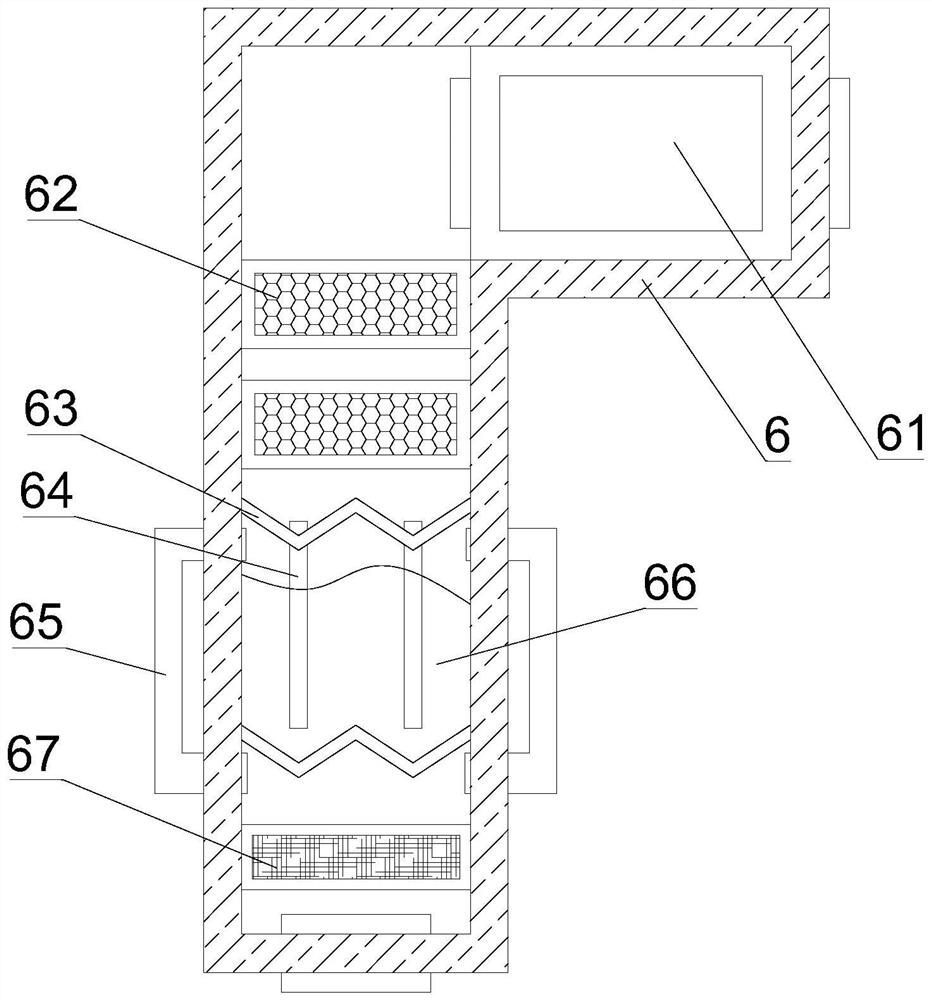

[0039] Such as Figure 1-7As shown, the present invention provides a protective cover structure for mechanical processing equipment, including a waste cooling device 1, a movable and closed protective glass door 2, a locking button 3, a material processor 4, a suction plate 5, and a purification air duct 6 and a workbench, a workbench is arranged on the top outer surface of the waste cooling device 1, a movable and closed protective glass door 2 is arranged on the outer surface of the workbench, and a locking button 3 is arranged on the outer surface of the movable and closed protective glass door 2, A material processor 4 is arranged on the outer surface of the workbench, a suction disk 5 is arranged on the top surface of the workbench, and a purification air guide pipe 6 is arranged on one side outer surface of the suction disk 5 .

[0040] In this embodiment, put the material on the workbench, close the mobile and closed protective glass door 2 and use the material processo...

Embodiment 2

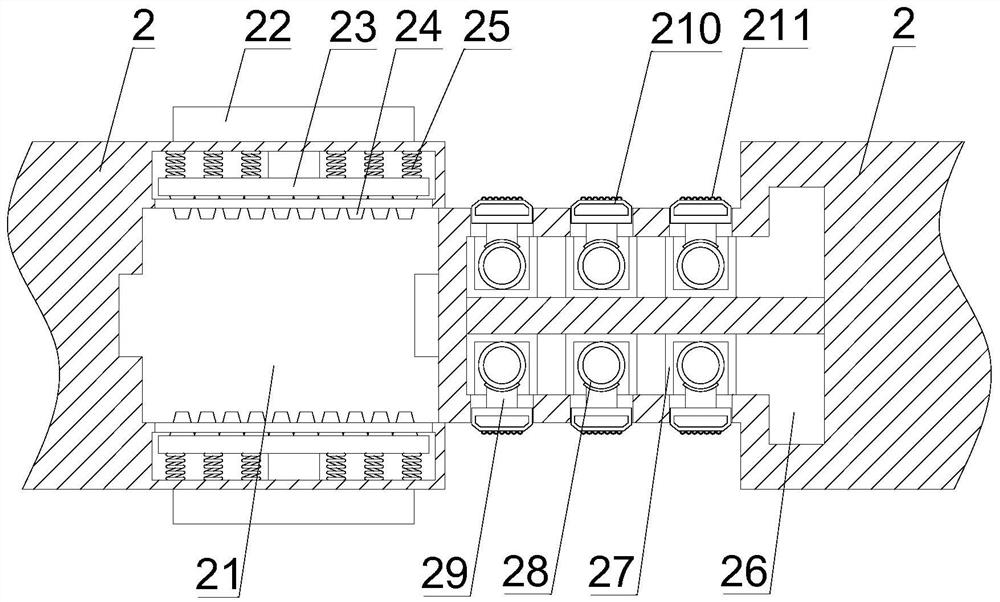

[0042] Such as Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a docking door frame is provided on one side of the outer surface of the movable and closed protective glass door 2, and a docking groove is provided on the outer surface of the docking door frame 21. The surface of the moving and closing protective glass door 2 is provided with a snap groove b1, and the outer surface of the snap groove b1 is provided with a protective glass b2, and the outer surface of the protective glass b2 is provided with a reinforced glass filament b3, and the butt joint groove 21 A pusher 22 is detachably installed on the outer surfaces of the upper and lower sides, and a push plate 23 is detachably connected to the output end of the pusher 22, and a trapezoidal extruded soft block is detachably connected to the outer surface of one side of the push plate 23 24. The outer surface of one side of the push plate 23 is provided...

Embodiment 3

[0045] Such as Figure 1-7 Shown, on the basis of embodiment 1, the present invention provides a kind of technical proposal: preferably, on the inner surface of both sides of the waste material cooling device 1, the waste material insulation board 11 is detachably connected, and the outer surface of the waste material insulation board 11 A gas-permeable layer 12 is provided, and the lower surface of the gas-permeable layer 12 is lapped with an air blowing head 13, and the top outer surface of the waste insulation plate 11 is detachably connected with a material guide inclined plate 14, and the right side of the waste cooling device 1 A rotator 15 is detachably installed on the outer surface of the side, and the output end of the rotator 15 is detachably connected with a rotating rod 16, and one end of the rotating rod 16 extends to the inner surface of the waste cooling device 1 and is movably overlapped on the guide swash plate On the outer surface of 14, an electromagnetic e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com