Production equipment for efficiently cutting, bending and carrying insulating film

A technology for production equipment and insulating film, which is applied in the field of battery box film sticking, can solve the problems of not being able to meet the quality and cycle requirements of thermal film sticking, the safety of operators, and the difficulty of cleaning the insulating film, etc., so as to improve the efficiency of thermal film sticking and reduce labor costs. The effect of labor intensity and precise size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

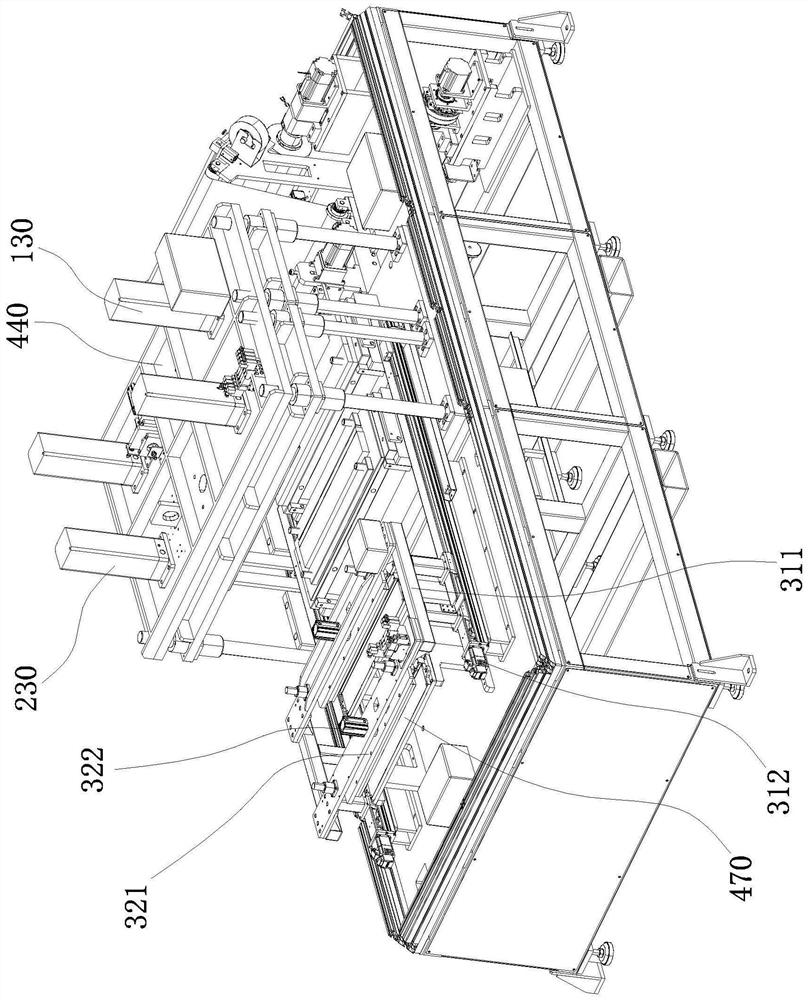

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

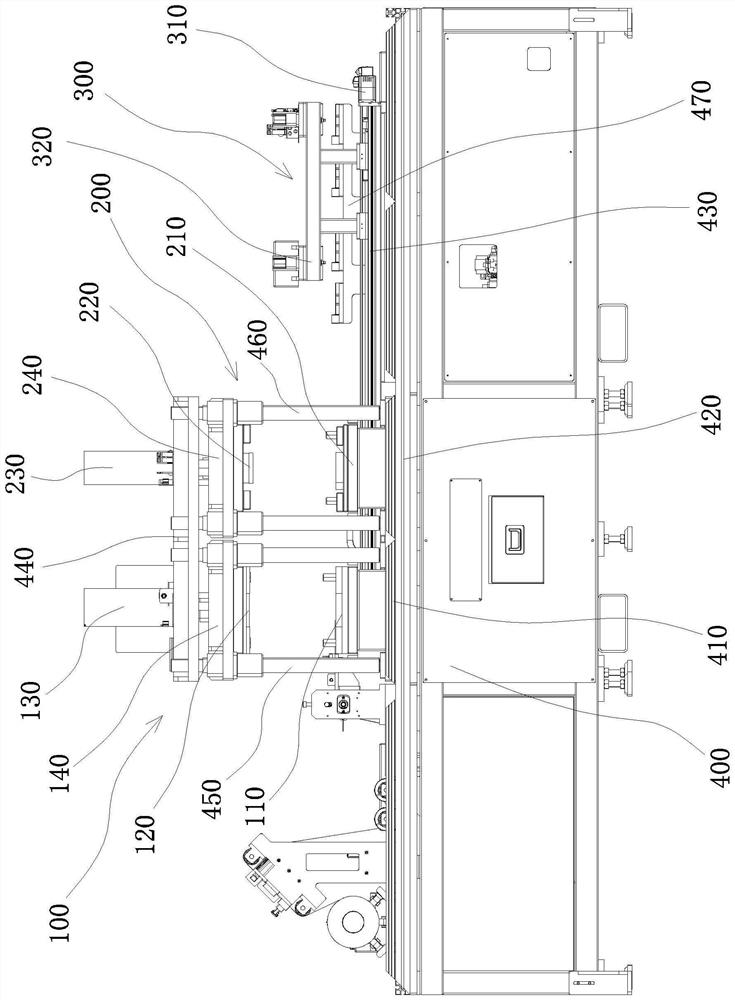

[0031] Such as Figure 1-4 As shown, a production equipment for efficient cutting, bending and handling of insulating films, including: a cutting mechanism 100, a bending mechanism 200, and a handling mechanism 300, through which the cutting mechanism 100 and the bending mechanism 200 can automatically realize insulation Cutting and bending of the film, and the insulating film can be transported by the transport mechanism 300, so that the insulating film can be transferred from the cutting mechanism 100 to the bending mechanism 200, and the insulating film can be taken away from the bending mechanism 200.

[0032] The cutting mechanism 100 includes a cutting template 110, a cutting knife 120 and a first driving element 130...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com