Wool discharging method for light and shadow composite tailoring mode of clothes

A light and shadow and clothing technology, applied in the direction of sewing tools, etc., can solve the problems of inaccurate fur laying accuracy, confusion of clothing sewing parking spaces, and reduction of clothing product quality, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

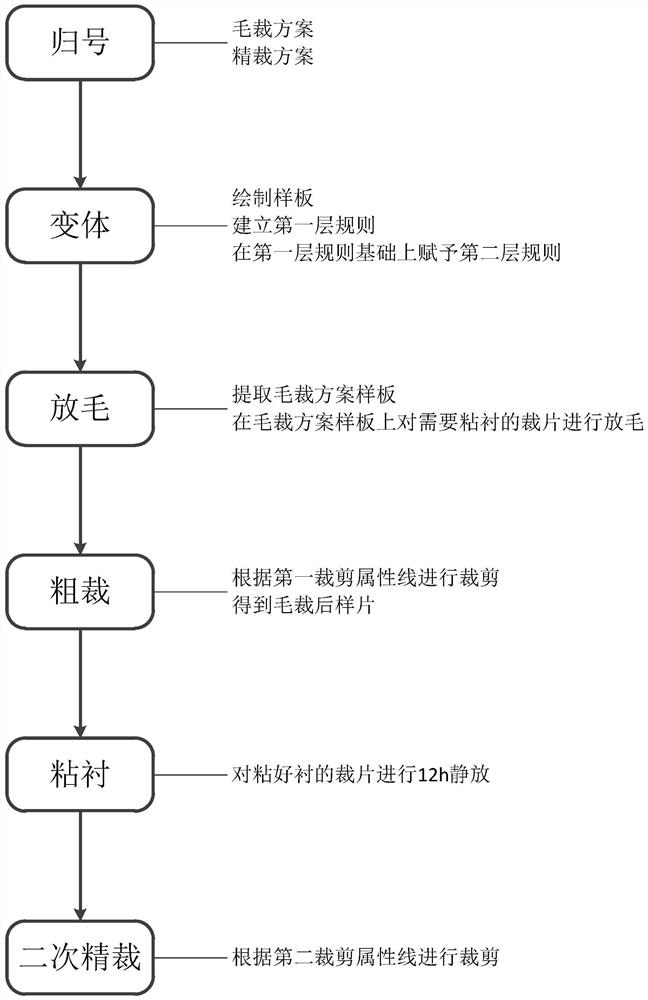

[0042] Such as figure 1 As shown, a kind of clothing light and shadow compound cutting mode of the present invention puts wool method comprises the following steps:

[0043] Step 1, numbering; refer to the specification table according to the order volume data, and sort out the order volume data;

[0044] Step 2, variant;

[0045] (1) Draw the model; the model painter draws the model according to the characteristics of the style;

[0046] (2) Establish the first layer of rules; according to the different models in the specification sheet, establish the first layer of rules for each reference point in the model;

[0047] (3) Establish the second layer of rules; according to the change rules of the special body shape, it is reflected in the establishment of the second layer of rules for each dimension, length, and parts with special body shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com