Adjustable stator blade and casing structure

A stator vane and casing technology, which is applied in the field of adjustable stator vane and casing structure, can solve problems such as torsional vibration and adjustable stator vane bending vibration, and achieve the effects of avoiding friction, eliminating interaction, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

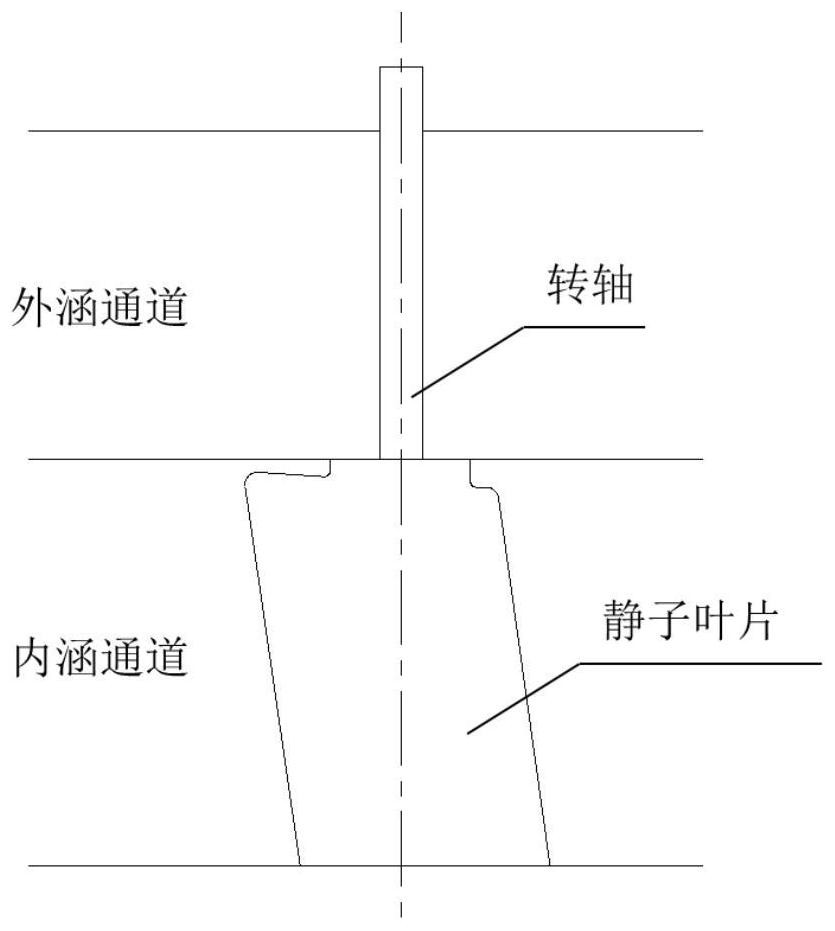

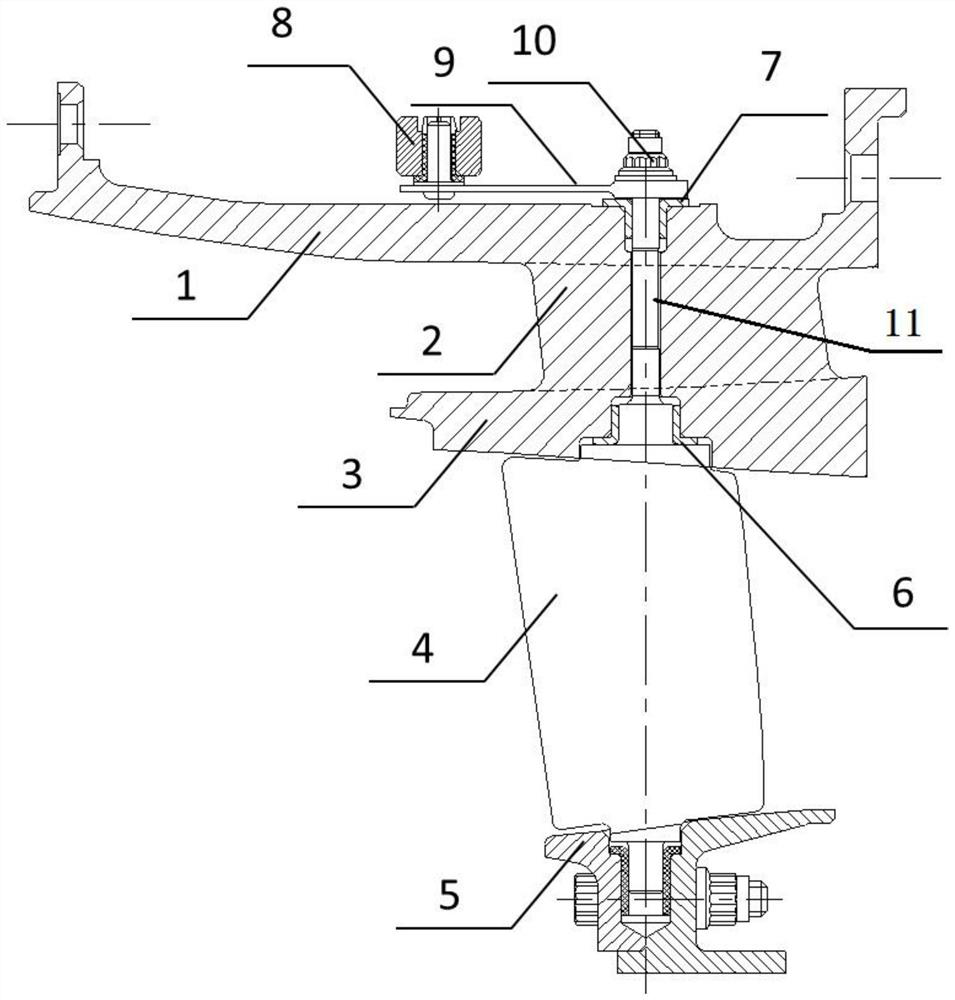

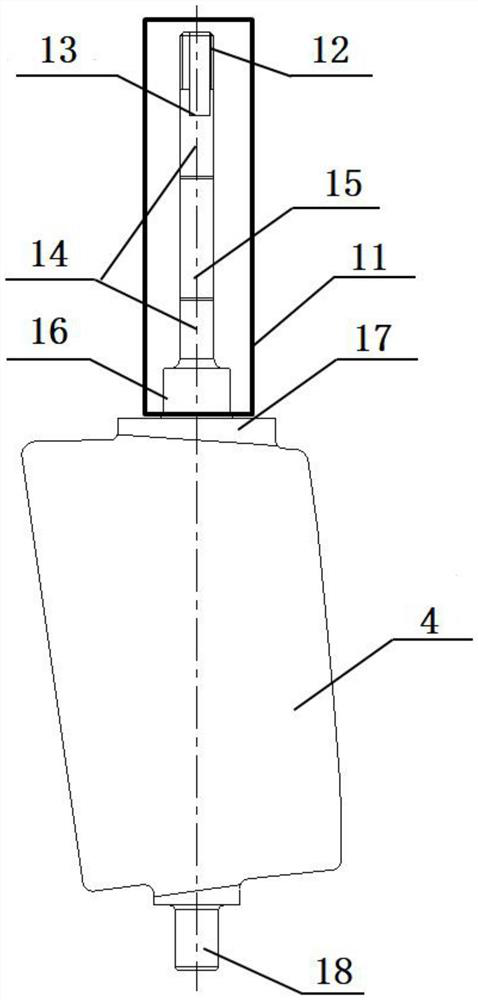

[0021] An adjustable stator vane and casing structure, such as figure 2 As shown, it includes adjustable stator vanes, inner casing 3 and outer casing 1. Both the inner casing 3 and the outer casing 1 are integral ring structures and coaxial with the axis of the compressor. The adjustable stator blades pass through the inner casing 3 and the outer casing 1 and protrude from the outer casing 1 . The inner side of the adjustable stator vane is provided with a stator inner ring 5, and the stator inner ring 5 and the adjustable stator vane are connected by bolts, an internal channel is formed between the inner casing 3 and the stator inner ring 5, and the inner casing 3 and the outer casing 1 Form the connotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com