Corrosion-resistant lining reaction tank

A corrosion-resistant, reaction tank technology, applied in the field of reaction tanks, can solve the problems of low production efficiency, difficulty in equipping material distributors and agitators, etc., and achieve the effect of good distribution and enhanced reaction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

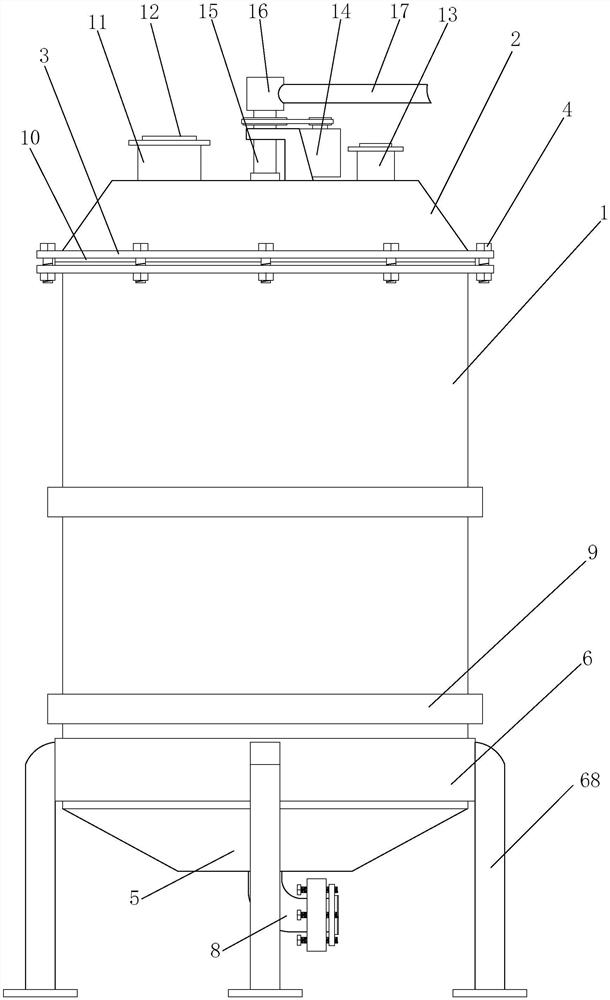

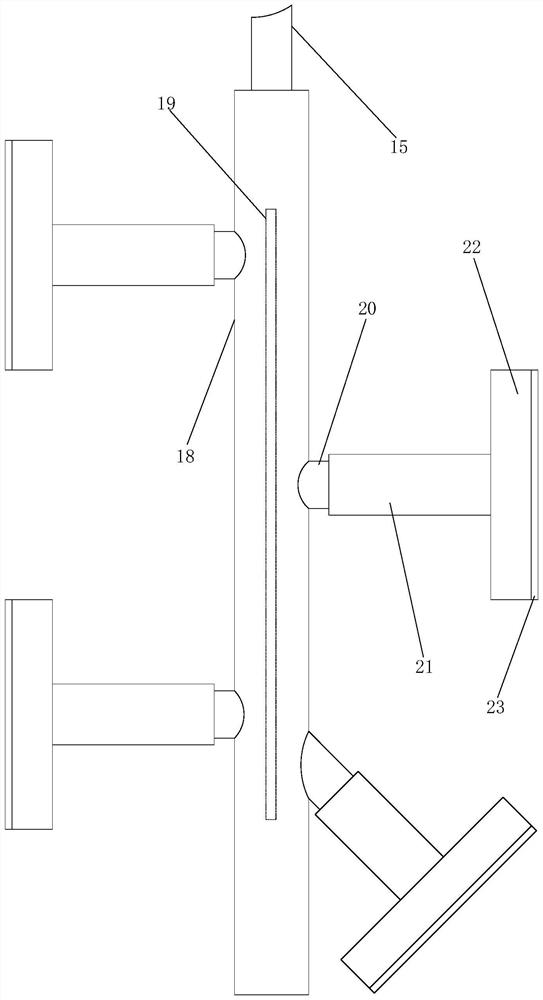

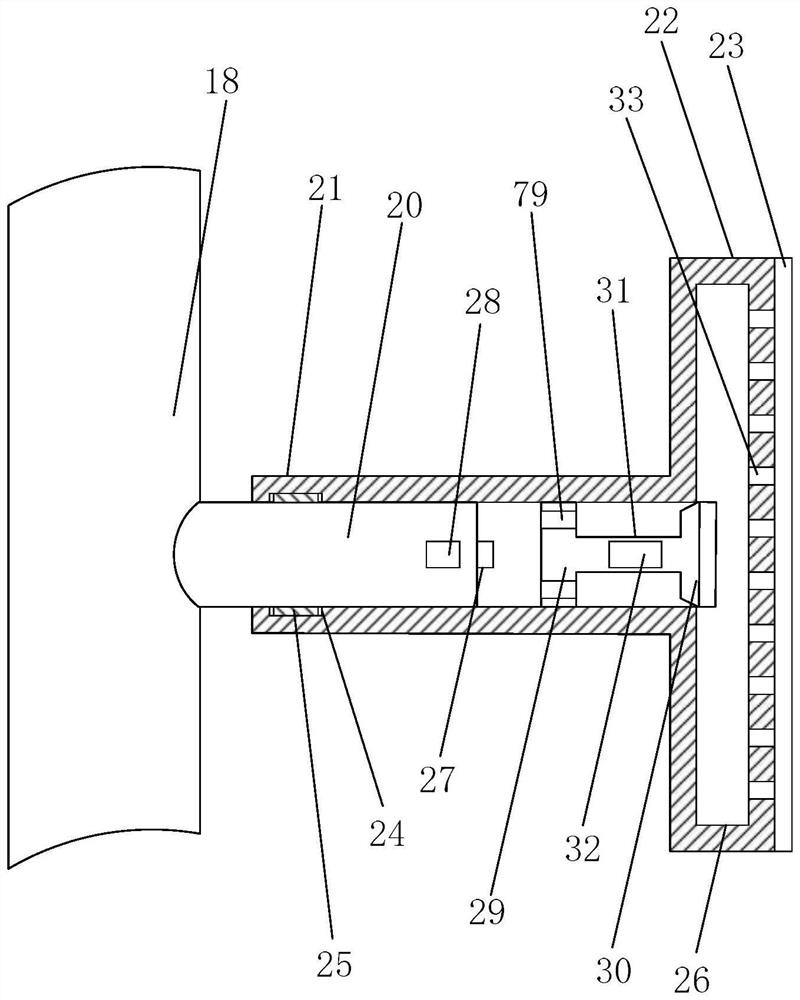

[0028] Such as Figure 1-10 As shown, the corrosion-resistant lined reaction tank disclosed in the present invention includes: a cylindrical tank body 1, a conical top cover 2, a corrosion-resistant distributor, a corrosion-resistant stirring and cleaning mechanism, and two distribution connectors;

[0029] A conical bottom 5 protrudes downward from the bottom of the cylindrical tank 1, and a discharge elbow 8 is connected to the conical bottom 5; the conical top cover 2 is sealed and installed on the cylindrical tank. 1, and on the conical top cover 2, there are main material inlets 11 and auxiliary material inlets 13; Corrosion-resistant lining layer 7, corrosion-resistant lining pipe 12 is arranged on the pipe inner wall of discharge elbow 8, main material inlet 11 and auxiliary material inlet 13; corrosion-resistant distributor is horizontally installed on the upper part of cylindrical tank body 1 Corrosion-resistant lining layer 7 of the main material and auxiliary mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com