Quick die changing device for forming machine

A molding machine, fast technology, applied in the field of rapid mold changing device, can solve the problems of time-wasting, consumption, unnecessary manpower, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

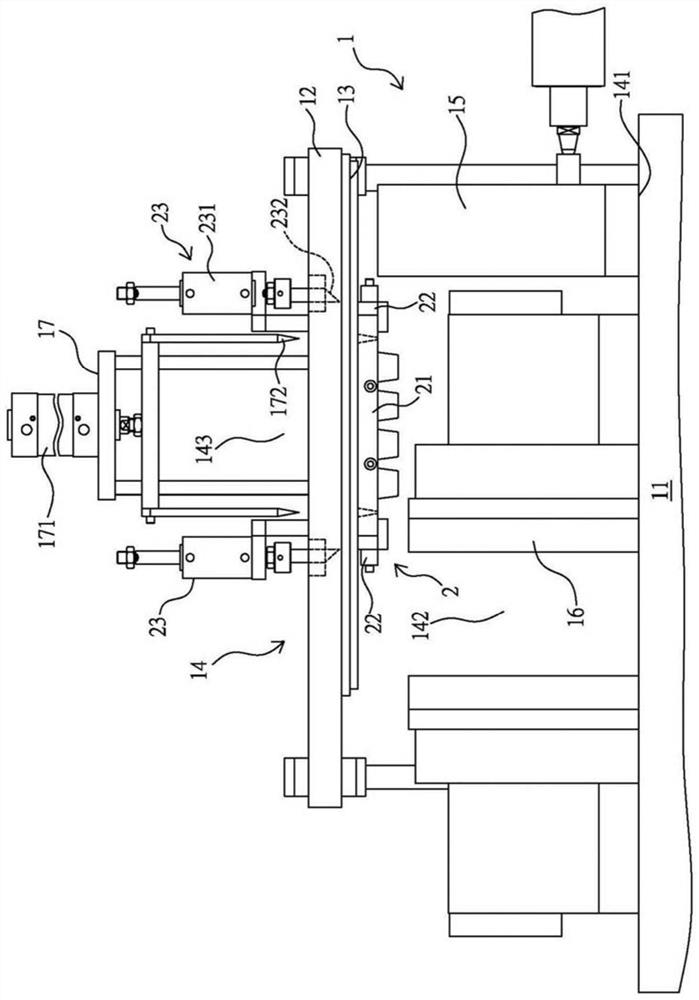

[0023] see figure 1 , which shows that the quick mold change device 2 provided by the embodiment of the present invention is installed on a molding machine 1, such as an elevating seat 12 above a worktable 11 of a vertical injection blow molding machine, and the bottom of the elevating seat 12 has a Lifting seat 12 is a turntable 13 that is lifted and lowered synchronously. Therefore this workbench 11 and this elevating seat 12 are provided with at least three operating stations 14 altogether, and these operating stations 14 include being located on this workbench 11 for an injection station 141 that an injection mold 15 is installed, for a A bottle blowing station 142 installed on the bottle blowing mold 16, and an ejection station 143 provided on the lifting base 12 for an ejection mechanism 17 to be installed.

[0024] If the molding machine 1 is a vertical injection molding machine, the workbench 11 and the lifting base 12 are provided with two operating stations 14, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com